Feeling lost in a sea of interview questions? Landed that dream interview for Electrical Discharge Machine Setup Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Electrical Discharge Machine Setup Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

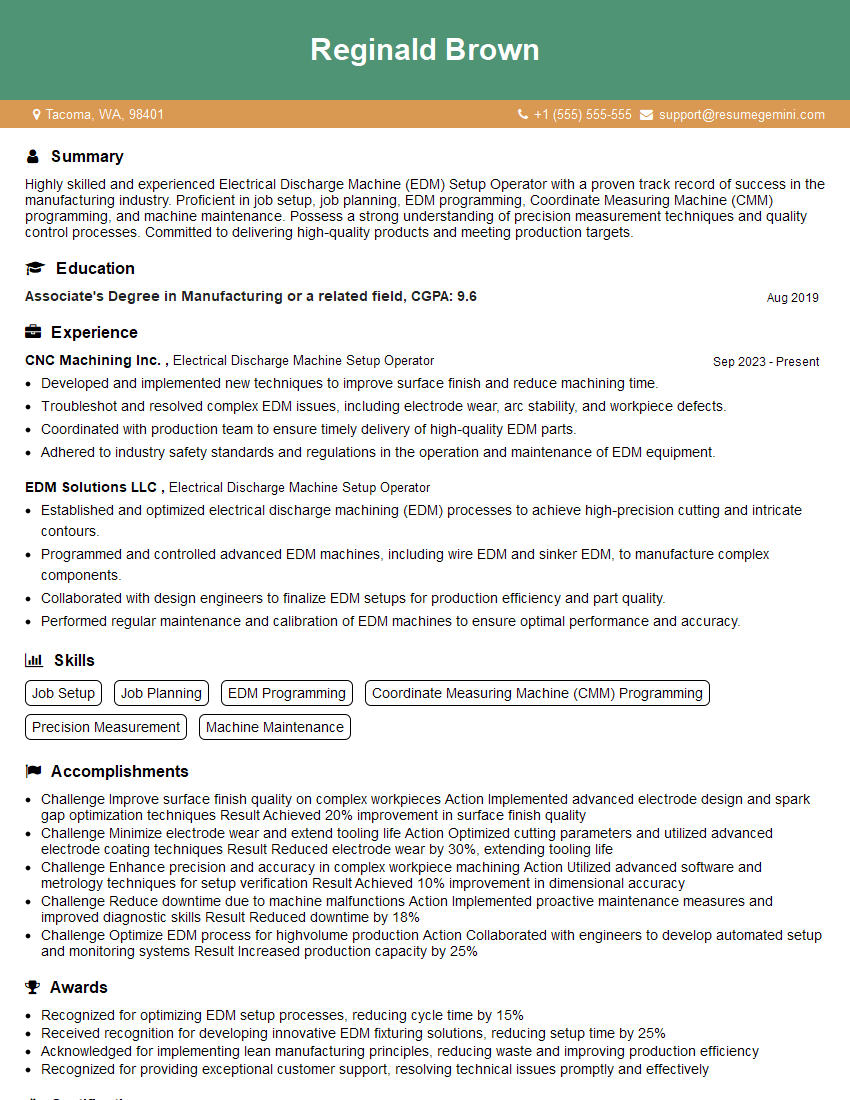

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrical Discharge Machine Setup Operator

1. Explain the process of setting up an Electrical Discharge Machine?

Setting up an Electrical Discharge Machine involves the following steps:

- Mounting the workpiece securely on the worktable.

- Installing the appropriate electrode and setting its position.

- Setting the machine parameters such as voltage, current, and pulse duration.

- Establishing the correct dielectric fluid level and flow rate.

- Conducting a test run to verify the setup and make any necessary adjustments.

2. Describe the different types of electrodes used in Electrical Discharge Machining?

Graphite electrodes

- Most commonly used due to their high conductivity and low cost.

- Suitable for roughing and finishing operations.

Copper electrodes

- Offer better surface finish and precision.

- Higher electrical conductivity than graphite.

Tungsten electrodes

- Used for high-precision and small-scale applications.

- Durable and resistant to wear.

3. How do you ensure the accuracy and repeatability of parts produced using Electrical Discharge Machining?

Ensuring accuracy and repeatability in EDM involves:

- Precise setup of the workpiece and electrode.

- Calibration and maintenance of the machine.

- Using high-quality electrodes and dielectric fluid.

- Optimizing machine parameters for each application.

- Implementing quality control measures and inspections.

4. What are the safety considerations when operating an Electrical Discharge Machine?

Safety considerations for EDM operation include:

- Wear appropriate personal protective equipment (PPE).

- Ensure proper ventilation to remove dielectric fumes.

- Keep the work area clean and free of debris.

- Use insulated tools when handling electrodes.

- Follow lockout/tagout procedures before performing maintenance.

5. How do you troubleshoot common problems encountered during Electrical Discharge Machining?

Troubleshooting common EDM problems involves:

- Identifying the symptoms of the problem.

- Checking the machine parameters and settings.

- Inspecting the electrode and workpiece.

- Verifying the dielectric fluid level and condition.

- Consulting technical documentation or seeking assistance from experienced personnel.

6. What are the advantages and limitations of Electrical Discharge Machining?

Advantages:

- Can machine complex and intricate shapes.

- Suitable for machining hard and brittle materials.

- Produces high-precision and high-quality surfaces.

- Low cutting forces, minimizing workpiece deformation.

Limitations:

- Relatively slow process compared to traditional machining.

- Limited depth of cut.

- Can be expensive due to electrode wear and dielectric fluid consumption.

7. How do you stay up-to-date with the latest advancements in Electrical Discharge Machining technology?

I stay updated with the latest advancements in EDM technology by:

- Attending industry conferences and exhibitions.

- Reading technical journals and industry publications.

- Participating in online forums and discussion groups.

- Seeking training and certification from manufacturers and industry experts.

8. Describe a specific project where you successfully applied Electrical Discharge Machining to solve a manufacturing challenge?

In a recent project, I used EDM to create a complex mold for a medical device. The mold required high precision and a smooth surface finish. Traditional machining methods were not able to achieve the desired results. By using EDM, I was able to accurately machine the mold and produce parts that met the required specifications.

9. What are your career goals and aspirations as an Electrical Discharge Machine Setup Operator?

My career goal is to become a highly skilled and experienced EDM setup operator, capable of handling complex and demanding projects. I aspire to contribute my expertise to the manufacturing industry and help organizations achieve their production goals and quality standards.

10. How do you manage working in a fast-paced and demanding manufacturing environment?

In a fast-paced manufacturing environment, I prioritize tasks, work efficiently, and maintain a high level of focus. I am adaptable and can quickly switch between different projects. I also communicate effectively with my team to ensure smooth operations and minimize disruptions. By leveraging my time management skills and commitment to quality, I am able to meet deadlines and exceed expectations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrical Discharge Machine Setup Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrical Discharge Machine Setup Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrical Discharge Machine Setup Operators are responsible for setting up, operating, and maintaining Electrical Discharge Machines (EDMs) to produce precision parts according to specifications.

1. Setup and Operation

Set up and operate EDMs to produce precision parts according to specifications and blueprints.

- Select and install appropriate electrodes and tooling.

- Set machine parameters, such as power, voltage, and pulse duration.

2. Maintenance and Repair

Maintain and repair EDMs to ensure optimal performance and production efficiency.

- Lubricate and clean machines regularly.

- Troubleshoot and repair electrical and mechanical issues.

3. Quality Control

Inspect finished parts to ensure they meet specifications and quality standards.

- Use precision measuring instruments to verify dimensions and tolerances.

- Perform quality control checks throughout the production process.

4. Documentation and Reporting

Document and report machine performance, production data, and any issues or maintenance activities.

- Maintain records of machine settings, tooling used, and production quantities.

- Report any deviations from specifications or production targets.

Interview Tips

To prepare for an Electrical Discharge Machine Setup Operator interview, candidates should:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Research the specific job requirements and responsibilities.

- Visit the company website and review their mission statement, values, and products.

- Read online reviews and articles about the company to gain insights into its culture and reputation.

2. Practice Your Answers to Common Interview Questions

Prepare answers to common interview questions, such as:

- Tell me about your experience with Electrical Discharge Machines.

- How do you ensure the quality of the parts you produce?

- What are your strengths and weaknesses as an Electrical Discharge Machine Setup Operator?

3. Prepare to Demonstrate Your Skills

If possible, be prepared to demonstrate your skills on an Electrical Discharge Machine during the interview. This could involve setting up the machine, operating it, or troubleshooting a problem.

- Practice operating an Electrical Discharge Machine before the interview.

- Bring a portfolio of your work, such as samples of parts you have produced.

4. Dress Professionally and Arrive on Time

Make a good first impression by dressing professionally and arriving on time for the interview. This shows that you are respectful of the interviewer’s time and that you take the position seriously.

- Wear clean and pressed business attire.

- Arrive at the interview location at least 15 minutes early.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Electrical Discharge Machine Setup Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.