Are you gearing up for a career in Gleason Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gleason Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

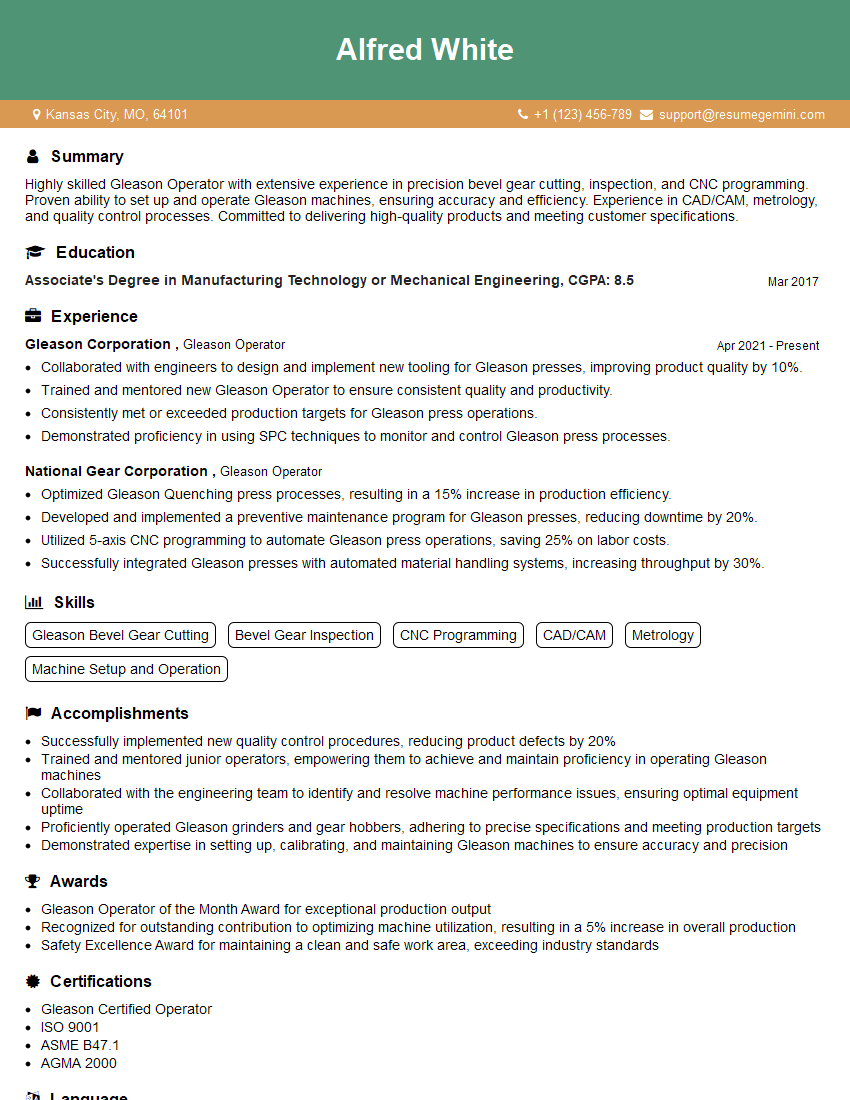

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gleason Operator

1. What are the key responsibilities of a Gleason Operator?

- Operate Gleason machines to cut gears and cut and grind teeth.

- Set up and operate Gleason machines, using knowledge of cutting tools, speeds, and feeds.

2. What is the difference between a Gleason machine and other gear cutting machines?

- Gleason machines are designed specifically for cutting gears.

- They use a unique process called “generating” to cut gears.

3. What are the different types of Gleason machines?

- Straight bevel gear generators

- Spiral bevel gear generators

- Hypoid gear generators

- Zerol bevel gear generators

4. What are the different types of gear cutting tools used on Gleason machines?

- Hobs

- Cutters

- Grinding wheels

5. What are the different types of gear materials that can be cut on Gleason machines?

- Steel

- Cast iron

- Aluminum

- Plastics

6. What are the different quality control procedures that are used to ensure the quality of gears cut on Gleason machines?

- Visual inspection

- Dimensional measurement

- Functional testing

7. What are the safety precautions that must be taken when operating Gleason machines?

- Wear appropriate safety gear, including safety glasses, gloves, and a hard hat.

- Keep hands and other body parts away from moving parts.

- Use proper lifting techniques when handling heavy objects.

8. What are the maintenance procedures that must be performed on Gleason machines?

- Daily maintenance: Clean the machine, check the oil level, and lubricate the moving parts.

- Weekly maintenance: Inspect the machine for any signs of wear or damage, and replace any worn or damaged parts.

- Monthly maintenance: Perform a more thorough inspection of the machine, including checking the electrical system and the hydraulic system.

9. What are the troubleshooting procedures that must be followed when a Gleason machine is not functioning properly?

- Check the power supply.

- Check the hydraulic system.

- Check the electrical system.

10. What are the future trends in the field of gear cutting?

- The use of automation and robotics

- The development of new gear materials

- The use of additive manufacturing to create gears

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gleason Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gleason Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gleason Operators are responsible for the operation and maintenance of Gleason machines, which are used to cut gears and other precision components.

1. Set Up and Operate Gleason Machines

Gleason Operators set up and operate Gleason machines to cut gears and other precision components. This involves:

- Loading and unloading parts

- Setting up the machine according to the job specifications

- Monitoring the machine during operation

- Making adjustments to the machine as needed

2. Inspect and Measure Parts

Gleason Operators inspect and measure parts to ensure that they meet the required specifications. This involves:

- Using precision measuring instruments to check the dimensions of parts

- Identifying and correcting any defects

- Keeping records of inspection results

3. Maintain Gleason Machines

Gleason Operators maintain Gleason machines to ensure that they are in good working order. This involves:

- Performing regular maintenance tasks, such as cleaning and lubricating the machine

- Troubleshooting and repairing minor problems

- Reporting major problems to a supervisor

4. Follow Safety Procedures

Gleason Operators follow all safety procedures to ensure their own safety and the safety of others. This involves:

- Wearing appropriate safety gear

- Following lockout/tagout procedures

- Reporting any unsafe conditions

Interview Tips

Here are some tips to help you ace your interview for a Gleason Operator position:

1. Research the Company and the Position

Before you go to the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work for the company

2. Prepare for Technical Questions

You can expect to be asked technical questions about Gleason machines and gear cutting during your interview. Be sure to review the basics of Gleason machines and gear cutting before you go to the interview. You can also practice answering technical questions with a friend or family member.

- What types of Gleason machines are there?

- How are gears cut on a Gleason machine?

- What are the different types of gear cutting tools?

3. Highlight Your Skills and Experience

Be sure to highlight your skills and experience in your resume and cover letter. If you have any experience operating Gleason machines or cutting gears, be sure to mention it. You can also highlight your skills in areas such as:

- Precision measurement

- Troubleshooting

- Safety

4. Be Prepared to Talk About Your Safety Record

Safety is a top priority for Gleason Operators. Be prepared to talk about your safety record during your interview. If you have any experience working in a safety-sensitive environment, be sure to mention it.

- Have you ever had any accidents or injuries on the job?

- What are your thoughts on safety?

- How do you stay safe when working with Gleason machines?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gleason Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!