Are you gearing up for an interview for a Machine Setter and Repairer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Machine Setter and Repairer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

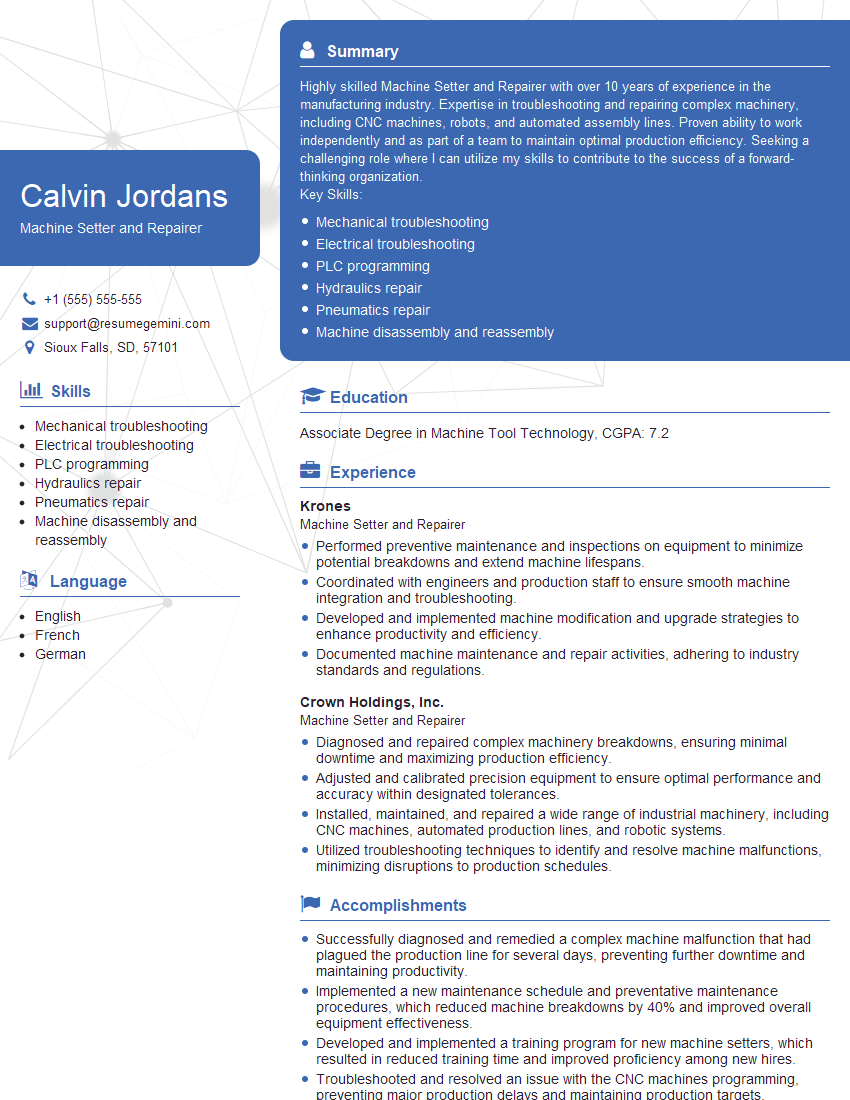

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Setter and Repairer

1. What are the key responsibilities of a Machine Setter and Repairer?

As a Machine Setter and Repairer, my key responsibilities include:

- Setting up and adjusting production machinery to meet specifications.

- Troubleshooting and repairing malfunctions.

- Performing preventive maintenance to ensure optimal machine performance.

- Inspecting and calibrating equipment to ensure accuracy and safety.

- Working with engineers and other technicians to identify and resolve technical issues.

2. Describe the different types of machines you have experience working with?

CNC Machines

- Experience in programming, operating, and maintaining CNC lathes, mills, and grinding machines.

- Proficient in using CAM software to generate toolpaths and optimize machine settings.

Injection Molding Machines

- Expertise in setting up, operating, and troubleshooting injection molding machines.

- Experience in mold design, process optimization, and quality control.

3. What safety precautions should be taken when working with machinery?

When working with machinery, I strictly adhere to the following safety precautions:

- Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Ensure that all machine guards are in place and functioning properly.

- Never attempt to clean or repair machinery while it is running.

- Follow lockout/tagout procedures to prevent accidental machine startup.

- Report any safety hazards or concerns promptly to supervisors or safety personnel.

4. What is your approach to troubleshooting machine malfunctions?

My approach to troubleshooting machine malfunctions involves a systematic and logical process:

- Identify the problem: Observe machine behavior, check error codes, and gather information from operators.

- Analyze the symptoms: Examine machine components, review settings, and consider possible causes.

- Determine the root cause: Use diagnostic tools, test equipment, and knowledge to pinpoint the underlying issue.

- Repair or replace: Implement necessary repairs or replacements using appropriate tools and techniques.

- Test and verify: Run test cycles to ensure the machine is functioning correctly and meets specifications.

5. How do you stay up-to-date with the latest advancements in machine technology?

To stay up-to-date with the latest advancements in machine technology, I engage in the following activities:

- Attend industry conferences and workshops.

- Read technical publications and online resources.

- Participate in online forums and discussion groups.

- Connect with other professionals in the field through social media.

- Seek opportunities for training and certification programs.

6. What are your strengths and weaknesses as a Machine Setter and Repairer?

Strengths:

- Strong technical skills in machine setup, adjustment, and troubleshooting.

- Experience with a variety of machine types, including CNC, injection molding, and automation systems.

- Excellent problem-solving and analytical abilities.

- Ability to work independently and as part of a team.

Weaknesses:

- Limited experience with some specialized machine technologies.

- Working under tight deadlines can sometimes lead to increased stress levels.

7. How do you handle situations where multiple machines require attention simultaneously?

When multiple machines require attention simultaneously, I prioritize tasks based on the following criteria:

- Urgency: Address critical issues that could lead to downtime or safety hazards first.

- Impact on production: Prioritize machines that have a significant impact on production goals.

- Availability of parts or resources: Consider the time and resources required to repair each machine.

- Safety: Immediately attend to any issues that pose a safety risk.

8. What is your experience with predictive maintenance techniques?

I have experience with the following predictive maintenance techniques:

- Vibration analysis: Monitoring machine vibrations to detect potential faults early.

- Thermography: Using thermal imaging to identify hotspots and potential electrical issues.

- Oil analysis: Analyzing oil samples to detect contamination, wear, and other signs of impending problems.

- Ultrasonic testing: Using ultrasonic waves to detect cracks, voids, and other material defects.

9. How do you ensure the accuracy and quality of your work?

To ensure the accuracy and quality of my work, I follow these practices:

- Thorough inspection: Carefully inspect machines, components, and settings before and after adjustments.

- Calibration and verification: Calibrate measuring instruments regularly and verify machine performance against established standards.

- Documentation: Maintain detailed records of all maintenance and repair activities, including machine settings, test results, and observations.

- Continuous improvement: Seek feedback from operators and supervisors to identify areas for improvement.

10. What are your career goals and how does this position align with them?

My career goal is to become a highly skilled and experienced Machine Setter and Repairer, specializing in advanced manufacturing equipment. This position aligns with my goals because it provides an opportunity to:

- Expand my knowledge of machine technologies.

- Develop my troubleshooting and repair skills.

- Contribute to the efficiency and productivity of a manufacturing organization.

- Advance my career through opportunities for growth and professional development.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Setter and Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Setter and Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Machine Setup and Operation

Prepare and set up machining equipment to ensure the production of high-quality components or products.

- Analyze engineering drawings and specifications to determine machine setups.

- Select and install cutting tools, fixtures, and accessories.

- Optimize cutting parameters and machine settings for maximum efficiency and precision.

- Monitor and adjust machine operation during production to maintain quality and productivity.

2. Machine Maintenance and Repair

Perform preventive maintenance and troubleshooting to keep machinery running smoothly.

- Lubricate and inspect machines to minimize wear and tear.

- Diagnose and resolve mechanical, electrical, and hydraulic issues.

- Repair or replace defective parts and components.

- Calibrate and align machines to ensure accuracy and repeatability.

3. Quality Control and Inspection

Inspect finished components and products to ensure they meet specifications and customer requirements.

- Use measuring tools and equipment to check dimensions, tolerances, and surface finishes.

- Identify any deviations or defects and take corrective actions.

- Maintain quality control records and report any non-conforming products.

- Participate in continuous improvement initiatives to enhance machine performance and product quality.

4. Safety and Compliance

Adhere to all safety regulations and company policies.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Maintain a clean and organized work environment.

- Dispose of hazardous materials properly.

Interview Tips

1. Research the Company and Position

Prior to the interview, thoroughly research the company and the specific role. This will demonstrate your interest and enthusiasm and allow you to ask informed questions.

- Visit the company’s website to learn about its values, mission, and products or services.

- Review the job description and identify the key responsibilities and skills required.

- Prepare questions that you can ask the interviewer to gain further insights into the position and company culture.

2. Highlight Your Skills and Experience

During the interview, clearly articulate your relevant skills and experience. Quantify your accomplishments whenever possible to provide tangible evidence of your abilities.

- Emphasize your expertise in machine setup, operation, and maintenance.

- Provide examples of how you have identified and resolved equipment issues in previous roles.

- Demonstrate your understanding of quality control procedures and inspection techniques.

- Highlight your commitment to safety and compliance.

3. Be Prepared to Answer Technical Questions

Machine Setter and Repairers are expected to possess a solid technical knowledge. Be prepared to answer questions about:

- Machine types and their capabilities.

- Cutting tool materials and selection.

- Machining processes and best practices.

- Preventive maintenance schedules and troubleshooting techniques.

- Quality assurance and inspection methods.

4. Ask Questions and Build Rapport

The interview is a two-way street. Ask thoughtful questions to demonstrate your genuine interest in the opportunity and to build rapport with the interviewer.

- Inquire about the immediate challenges facing the machine shop.

- Ask for details about the company’s growth plans and how the position fits into those plans.

- Share your ideas on how you can contribute to the team’s success.

- Thank the interviewer for their time and express your enthusiasm for the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Setter and Repairer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.