Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Nickel Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

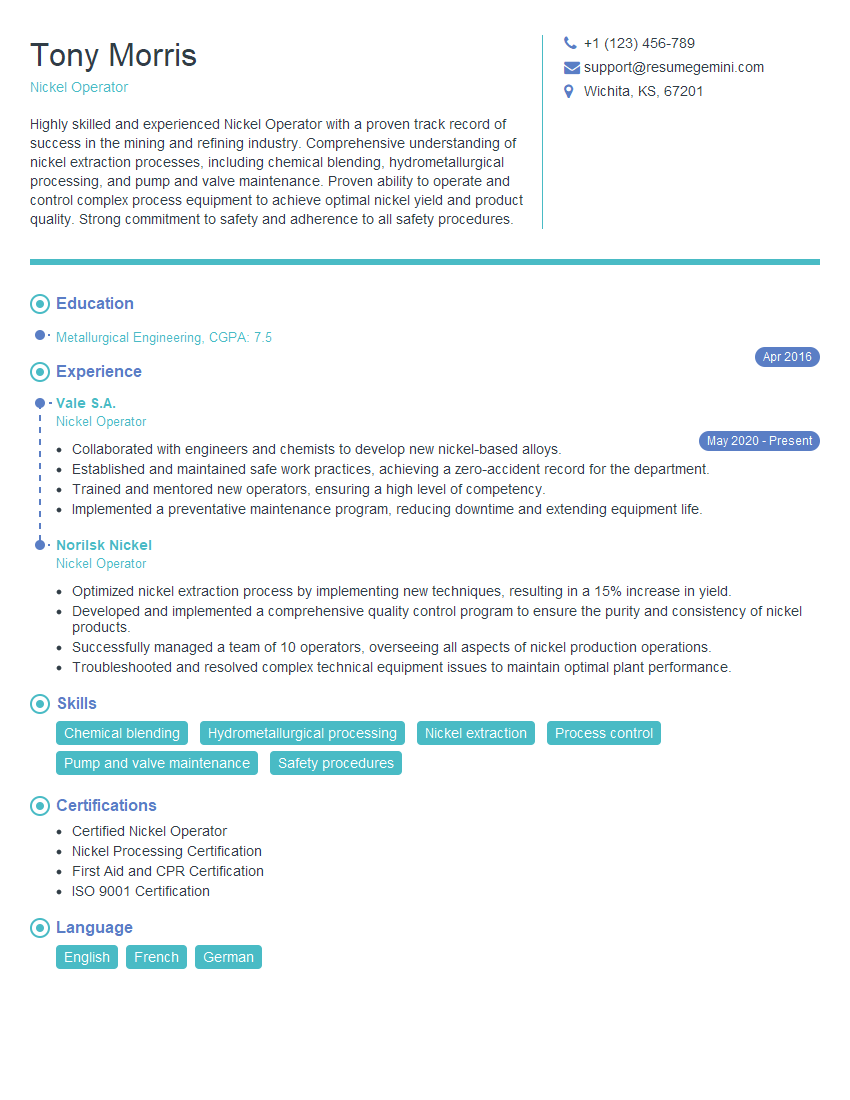

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nickel Operator

1. What are the primary responsibilities of a Nickel Operator?

The primary responsibilities of a Nickel Operator typically include:

- Monitoring and controlling the nickel refining process to ensure optimal production

- Maintaining and calibrating process equipment, including pumps, valves, and instruments

- Troubleshooting and resolving process issues and equipment malfunctions

- Adhering to safety regulations and procedures to ensure a safe and compliant work environment

2. Describe the key technical skills required to be successful in this role?

Process Knowledge

- Thorough understanding of the nickel refining process and its various stages

- Familiarity with the equipment and instrumentation used in nickel refining

Troubleshooting Abilities

- Ability to identify and diagnose process issues quickly and accurately

- Experience in resolving equipment malfunctions and optimizing process performance

Safety Compliance

- In-depth knowledge of safety regulations and procedures in the nickel refining industry

- Commitment to maintaining a safe and compliant work environment

3. How do you stay updated with the latest advancements in nickel refining technology?

To stay updated with the latest advancements in nickel refining technology, I regularly engage in the following practices:

- Attending industry conferences and workshops

- Reading technical journals and research papers

- Consulting with experts in the field

- Participating in online forums and discussion groups

4. What are the challenges you anticipate facing as a Nickel Operator, and how do you plan to overcome them?

Some challenges I anticipate facing as a Nickel Operator include:

- Process optimization: Continuously improving process efficiency and reducing production costs

- Equipment maintenance: Ensuring the reliability and availability of process equipment

- Safety compliance: Maintaining a safe and compliant work environment

To overcome these challenges, I plan to:

- Leverage my technical expertise to identify and implement process improvements

- Develop a proactive maintenance plan to minimize equipment downtime

- Stay informed about the latest safety regulations and best practices

5. What are your strengths and weaknesses as they relate to this role?

Strengths

- Strong understanding of the nickel refining process

- Proven troubleshooting and problem-solving skills

- Excellent communication and interpersonal skills

Weaknesses

- Limited experience with specific nickel refining equipment

- Still developing knowledge of the latest safety regulations

6. What is your understanding of the principles of electrorefining in nickel production?

Electrorefining is a key process in nickel production, where impure nickel is purified through electrolysis. My understanding of its principles includes:

- Nickel anodes are dissolved in an electrolyte solution, releasing nickel ions

- Nickel ions are deposited onto pure nickel cathodes, forming high-purity nickel

- Impurities remain in the electrolyte or form anode slimes

7. How would you prioritize tasks in a fast-paced nickel refining environment?

In a fast-paced nickel refining environment, I would prioritize tasks based on the following criteria:

- Safety: Any tasks related to safety would have the highest priority

- Production: Tasks critical to maintaining or increasing production would be next in priority

- Maintenance: Preventive maintenance tasks would be scheduled regularly to minimize downtime

- Administrative: Non-urgent administrative tasks would be handled as time permits

8. What are the environmental considerations and regulations that apply to nickel refining operations?

Nickel refining operations must comply with various environmental regulations to minimize their impact on the environment. These include:

- Air pollution control to reduce emissions of sulfur dioxide and particulate matter

- Water treatment to remove heavy metals and other contaminants

- Waste management to properly dispose of hazardous materials

9. Describe your experience in working with automated control systems in a nickel refining plant.

In my previous role as a Nickel Operator, I was responsible for monitoring and controlling the nickel refining process using an automated control system. My experience includes:

- Maintaining and calibrating sensors and transmitters

- Troubleshooting and resolving control system issues

- Optimizing process parameters to improve efficiency

10. How do you ensure the quality of nickel products produced in a refining operation?

Ensuring the quality of nickel products involves the following steps:

- Regular sampling and testing of nickel products

- Monitoring process parameters to identify deviations from specifications

- Implementing corrective actions to maintain product quality

- Adhering to established quality control procedures

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nickel Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nickel Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Controlling and Monitoring Plant Operations

Operate and maintain nickel processing equipment, including furnaces, crushers, and conveyors.

- Adjust process parameters to optimize production and minimize waste.

- Monitor equipment for proper functionality and make necessary adjustments.

- Troubleshoot and resolve operational issues.

2. Ensuring Product Quality

Ensure adherence to quality standards and specifications.

- Conduct routine inspections and tests on nickel products.

- Identify and correct defects in the production process.

- Maintain records of quality control measures.

3. Health, Safety, and Environmental Compliance

Adhere to all applicable health, safety, and environmental regulations.

- Follow proper safety protocols and wear appropriate protective gear.

- Monitor emissions and ensure compliance with environmental standards.

- Handle hazardous materials in accordance with regulations.

4. Team Collaboration and Communication

Collaborate effectively with other team members and supervisors.

- Communicate information about process status and any potential issues.

- Provide training and support to less experienced operators.

- Participate in problem-solving and improvement initiatives.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips and hacks to help you ace your interview for a Nickel Operator position:

1. Research the Company and Role

Before the interview, take the time to thoroughly research the company and the specific role you are applying for. This will give you a good understanding of their business, values, and the specific tasks and responsibilities involved in the job.

- Visit the company’s website to learn about their history, mission, products/services, and culture.

- Read industry news and articles to stay informed about the latest trends and developments in the nickel industry.

- Review the job description thoroughly to understand the key requirements and expectations of the role.

2. Practice Your Answers to Common Interview Questions

There are certain interview questions that are commonly asked in most Nickel Operator interviews. By practicing your answers to these questions in advance, you can become more confident and articulate during the interview.

- Tell me about your experience in operating nickel processing equipment.

- Describe a situation where you had to troubleshoot and resolve a complex operational issue.

- How do you ensure that nickel products meet quality standards and specifications?

- What are your strengths and weaknesses as a Nickel Operator?

- Why are you interested in working for our company?

3. Highlight Your Skills and Experience

During the interview, make sure to highlight your skills and experience that are relevant to the job requirements. Be specific and provide examples to support your claims.

- Emphasize your experience in operating and maintaining nickel processing equipment.

- Provide examples of how you have ensured product quality and met stringent industry standards.

- Discuss your knowledge of health, safety, and environmental regulations and how you have ensured compliance in your previous roles.

4. Ask Thoughtful Questions

At the end of the interview, you will typically be given an opportunity to ask questions. This is your chance to show the interviewer that you are engaged, interested, and have given the interview some thought.

- Ask about the company’s growth plans and future prospects.

- Inquire about opportunities for professional development and advancement within the organization.

- Ask about the company’s commitment to sustainability and environmental responsibility.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nickel Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!