Feeling lost in a sea of interview questions? Landed that dream interview for Plastic Finisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plastic Finisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

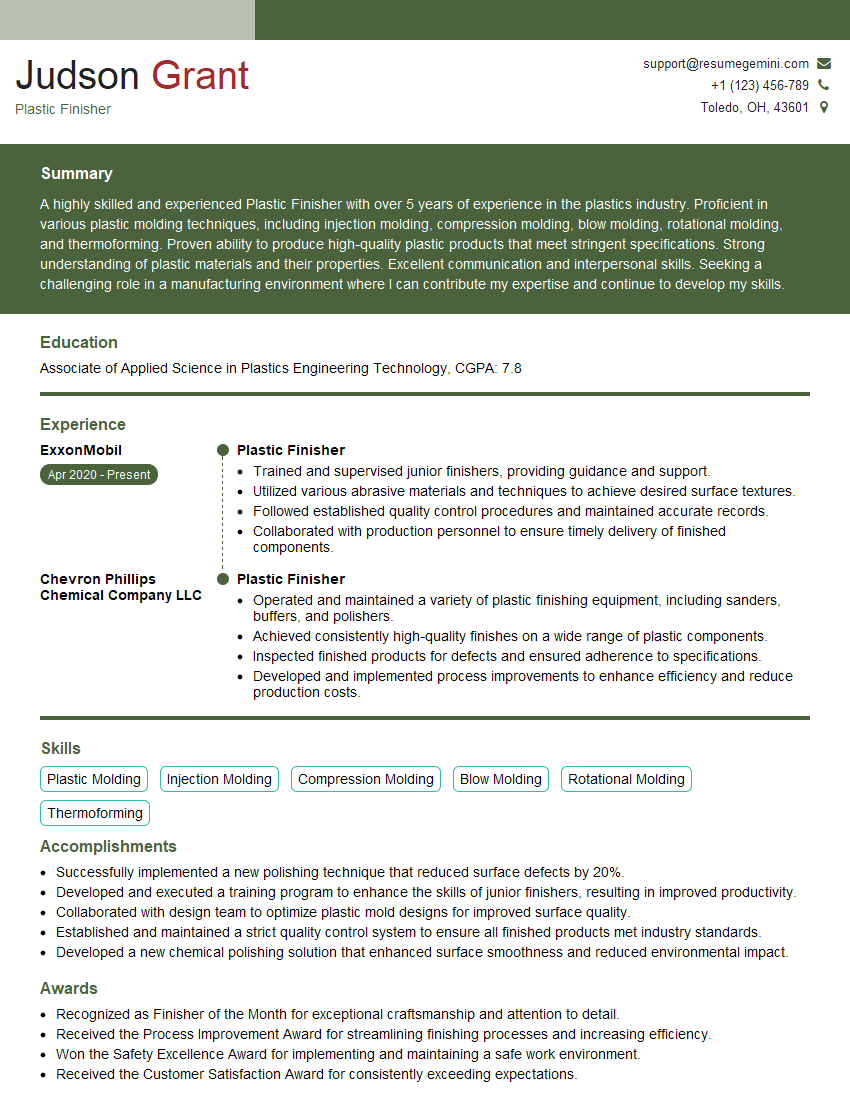

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Finisher

1. What are the different methods of plastic finishing?

- Mechanical finishing: This includes processes such as sanding, buffing, and polishing, which use abrasive materials to remove material from the plastic surface.

- Chemical finishing: This involves the use of chemicals to alter the surface properties of the plastic, such as etching, electroplating, and anodizing.

- Thermal finishing: This uses heat to change the surface properties of the plastic, such as annealing, heat treating, and welding.

2. What are the key factors to consider when selecting a plastic finishing method?

Surface finish requirements:

- The desired surface finish will determine the appropriate finishing method.

- For example, a smooth, glossy finish may require polishing, while a textured finish may require sanding.

Material properties:

- The type of plastic being finished will affect the choice of finishing method.

- For example, some plastics are more sensitive to heat than others.

Production volume:

- The number of parts being finished will influence the choice of finishing method.

- For example, high-volume production may require automated finishing processes.

3. What are the common defects that can occur during plastic finishing?

- Scratches and gouges

- Burns and discolorations

- Warpage and distortion

- Chemical contamination

- Surface imperfections

4. How do you ensure quality control in plastic finishing?

- Establish clear specifications and tolerances

- Use appropriate inspection and testing methods

- Monitor and adjust finishing processes as needed

- Document and maintain quality records

5. What are the latest trends in plastic finishing?

- Increased automation and robotics

- Development of new finishing materials and techniques

- Focus on sustainable and environmentally friendly processes

6. Describe your experience in using sanding equipment for plastic finishing.

I have extensive experience in using a variety of sanding equipment for plastic finishing, including orbital sanders, belt sanders, and disc sanders.

I am proficient in using these machines to achieve the desired surface finish, while minimizing material removal and avoiding defects.

I have also developed and implemented sanding processes to improve efficiency and productivity.

7. Explain how you would troubleshoot a problem with a plastic finishing process.

- Identify the problem and its potential causes

- Gather data and analyze the process

- Develop and test potential solutions

- Implement the solution and monitor its effectiveness

8. What is your understanding of the safety procedures for plastic finishing?

- Wear appropriate personal protective equipment (PPE)

- Operate equipment safely and according to manufacturer’s instructions

- Handle and dispose of chemicals properly

- Maintain a clean and organized work area

- Be aware of potential hazards and take appropriate precautions

9. How do you stay up-to-date with the latest advances in plastic finishing?

- Attend industry events and conferences

- Read trade publications and technical articles

- Participate in online forums and discussions

- Network with other professionals in the field

10. Why do you think you are the best candidate for this plastic finisher position?

- I have the skills, experience, and knowledge required to perform the job effectively.

- I am a highly motivated and results-oriented individual with a strong work ethic.

- I am eager to learn and grow in this role and contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Finishers are responsible for preparing, smoothing, and finishing plastic surfaces for manufacturing and production processes. They are part of the manufacturing team and work closely with engineers, designers, and other tradespeople to complete projects accurately and efficiently.

1. Preparing Surfaces

Plastic Finishers start by preparing the surface of the plastic, using techniques such as sanding, grinding, and polishing.

- Sanding involves using abrasive paper or cloth to smooth and remove imperfections from the plastic surface.

- Grinding is a more aggressive process that uses a rotating abrasive wheel to remove excess material and create a smooth finish.

- Polishing is a final step that uses a soft abrasive to create a glossy and reflective finish.

2. Cleaning and Inspecting

Once the surface is prepared, Plastic Finishers clean and inspect it to ensure it meets the required specifications and quality standards.

- Cleaning involves using solvents, detergents, and other cleaning agents to remove any contaminants or debris.

- Inspection involves visually checking the surface for any defects, such as scratches, dents, or voids.

3. Applying Coatings

In some cases, Plastic Finishers may also apply coatings to the surface of the plastic to enhance its properties.

- Coatings can be used to protect the plastic from UV radiation, chemicals, or scratches.

- They can also be used to improve the appearance of the plastic or to provide a specific texture.

4. Completing Projects

Plastic Finishers work closely with engineers and designers to complete projects on time and within budget.

- They may be responsible for assembling components, installing hardware, and ensuring that the finished product meets all specifications.

- They may also provide input on the design and development process to ensure that the final product is of the highest quality.

Interview Tips

Preparing for an interview for a Plastic Finisher position requires research, practice, and confidence. Review the job description and highlight your relevant skills and experience. Consider the following tips to enhance your chances of success.

1. Research the Company and Role

Learn about the company’s history, values, and the specific industry they operate in. Understand the responsibilities of the Plastic Finisher role and how it aligns with your capabilities.

- Visit the company website and read industry publications to gather information.

- If possible, connect with current or former employees on LinkedIn to gain insights.

2. Highlight Your Technical Skills

Emphasize your proficiency in plastic surface preparation techniques such as sanding, grinding, polishing, and cleaning. Quantify your experience with specific tools and equipment.

- Provide examples of projects where you successfully completed plastic finishing tasks.

- Mention any certifications or specialized training you have received.

3. Showcase Your Quality Assurance Mindset

Demonstrate your commitment to quality by explaining your attention to detail and adherence to industry standards. Highlight your experience in inspecting plastic surfaces for defects and ensuring that they meet specifications.

- Share examples of how you have identified and resolved quality issues in previous roles.

- Discuss your knowledge of quality control processes and best practices.

4. Articulate Your Teamwork Abilities

Plastic Finishers often work as part of a team in manufacturing and production environments. Emphasize your ability to collaborate with engineers, designers, and other tradespeople to complete projects efficiently.

- Provide examples of how you have worked effectively in a team setting.

- Highlight your communication and interpersonal skills.

5. Practice and Prepare

Practice answering common interview questions related to your skills, experience, and motivation. Prepare questions to ask the interviewer to demonstrate your interest and engagement. Research the industry and prepare talking points on current trends and advancements.

- Conduct mock interviews with a friend or family member.

- Dress professionally and arrive on time for the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastic Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!