Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plastic Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plastic Worker so you can tailor your answers to impress potential employers.

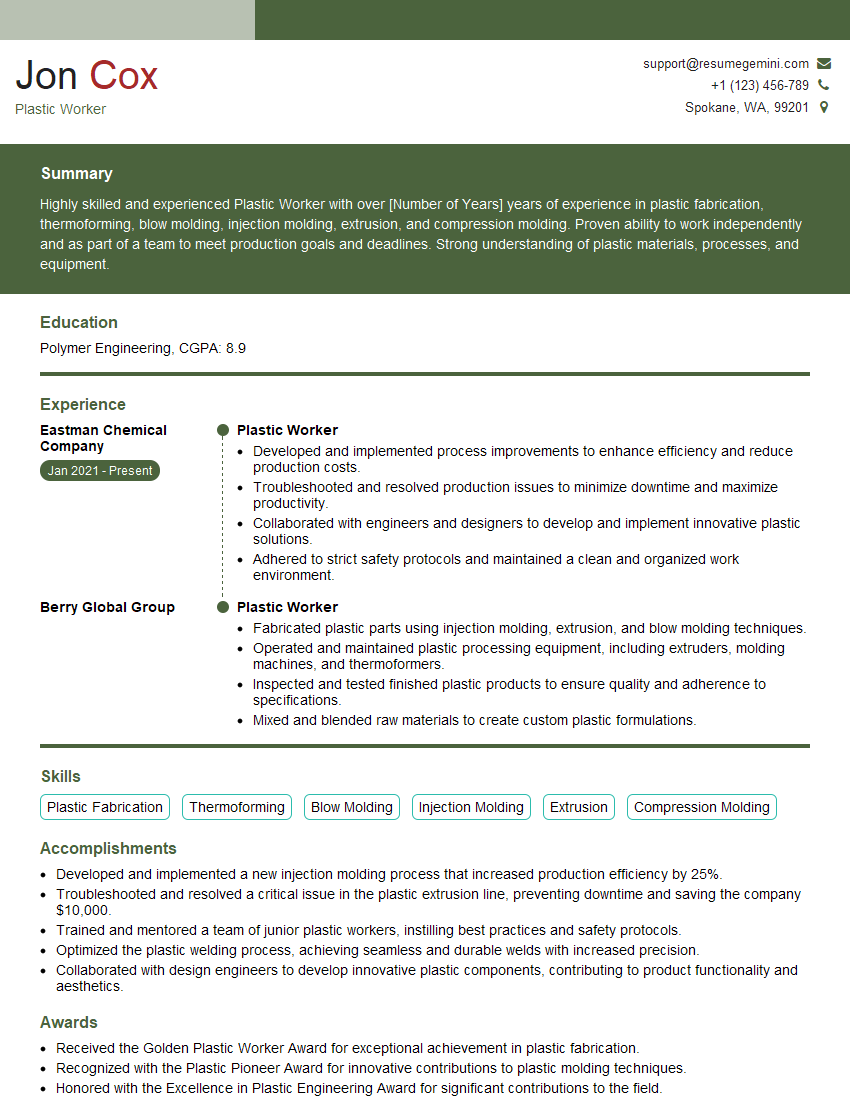

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Worker

1. What are the different types of plastics and their applications?

- Thermoplastics: These plastics can be repeatedly softened by heat and solidified by cooling, making them suitable for molding and shaping. Examples include polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC).

- Thermosets: These plastics undergo irreversible chemical changes upon heating, resulting in a rigid and durable structure. Examples include epoxy, polyester, and phenolic resins.

- Elastomers: These plastics exhibit rubber-like properties, making them flexible and elastic. Examples include natural rubber, synthetic rubber, and silicone.

- Bioplastics: These plastics are derived from renewable resources, such as plant materials or microorganisms. Examples include polylactic acid (PLA) and cellulose acetate.

2. Describe the process of injection molding and its advantages and disadvantages.

Advantages

- High precision and accuracy in producing complex shapes.

- Fast production rates due to automation.

- Suitable for mass production of identical parts.

- Good surface finish and dimensional stability.

Disadvantages

- High initial investment cost for molds and equipment.

- Limited to thermoplastics and requires high-pressure molding.

- Can produce sink marks and warpage if not properly controlled.

3. Explain the different methods of welding plastics and their applications.

- Heat welding: This method uses heat to melt and fuse plastic surfaces together. It can be done using hot air, ultrasonic waves, or electromagnetic radiation.

- Solvent welding: This method uses a solvent to dissolve the plastic surfaces, which then fuse together upon evaporation of the solvent.

- Mechanical welding: This method uses mechanical force to join plastic surfaces, such as by using staples, rivets, or screws.

4. What are the different types of plastic extrusion processes and their applications?

- Extrusion blow molding: This process involves extruding molten plastic into a tube, which is then inflated with air to form a hollow shape.

- Film extrusion: This process produces thin sheets of plastic by extruding molten plastic through a flat die.

- Pipe extrusion: This process produces continuous lengths of plastic pipe by extruding molten plastic through a circular die.

5. Describe the different types of plastic molding processes and their applications.

- Compression molding: This process involves placing a plastic powder or granules into a heated mold and applying pressure to form the desired shape.

- Transfer molding: This process involves injecting molten plastic into a heated mold under pressure.

- Rotational molding: This process involves placing plastic powder or granules into a heated mold, which is then rotated to distribute the plastic evenly and form the desired shape.

6. What are the different factors that affect the quality of plastic products?

- Raw material quality and purity

- Mold design and condition

- Processing parameters (temperature, pressure, speed)

- Additives and fillers

- Environmental conditions (humidity, temperature)

7. Explain the principles of plastic recycling and its importance.

- Plastic recycling involves reprocessing waste plastic materials to produce new plastic products.

- It is important for reducing plastic waste, conserving natural resources, and preventing pollution.

- Different types of plastics have different recycling processes, based on their chemical structure and properties.

8. Describe the different types of plastic testing methods and their applications.

- Mechanical testing: This includes tests to determine tensile strength, impact resistance, and flexural modulus.

- Thermal testing: This includes tests to determine melting point, glass transition temperature, and thermal conductivity.

- Electrical testing: This includes tests to determine electrical conductivity, dielectric strength, and insulation resistance.

9. What are the emerging trends and advancements in the plastics industry?

- Bioplastics and biodegradable plastics

- Additive manufacturing and 3D printing

- Plastic electronics and flexible devices

- Nanotechnology in plastics

10. Explain the importance of health and safety in the plastics industry.

- Plastic workers may be exposed to hazardous materials, such as solvents, chemicals, and dust.

- Proper ventilation, protective equipment, and safety protocols are essential to prevent accidents and health risks.

- Regular training and awareness programs are crucial for maintaining a safe work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Workers are responsible for a variety of tasks related to the production and maintenance of plastic products. Their duties may include:

1. Operating machinery

Plastic Workers use a variety of machines to create and modify plastic products. These machines may include injection molding machines, extruders, and thermoformers.

- Setting up and operating machinery

- Inspecting products for quality

- Making adjustments to machinery to ensure correct operation

2. Preparing raw materials

Plastic Workers prepare raw materials for use in the production process. This may involve mixing different types of plastics, adding colors or other additives, and preparing molds or forms.

- Mixing and blending different types of plastic

- Adding colors or other additives

- Preparing molds or forms for use in production

3. Inspecting products

Plastic Workers inspect products for quality and defects. They may use a variety of tools to check for things like cracks, scratches, or other imperfections.

- Using a variety of tools to check for defects

- Identifying and correcting defects

- Rejecting products that do not meet quality standards

4. Maintaining equipment

Plastic Workers are responsible for maintaining the equipment they use in the production process. This may involve cleaning, lubricating, and repairing machinery.

- Cleaning and lubricating machinery

- Repairing minor problems

- Reporting major problems to supervisors

Interview Tips

In order to ace an interview for a Plastic Worker position, it is important to be prepared and to know what the interviewer is looking for. Here are a few tips:

1. Research the company

Before you go to your interview, take some time to research the company. This will help you understand their business, their culture, and their values. It will also help you to tailor your answers to the interviewer’s questions.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work for the company

2. Practice your answers

Take some time to practice answering common interview questions. This will help you to feel more confident and prepared during your interview.

- Think about your skills and experience

- Prepare examples of your work

- Practice answering different types of questions

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and avoiding casual attire.

- Choose clothes that are appropriate for the job

- Make sure your clothes are clean and pressed

- Avoid wearing casual attire

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, call the interviewer to let them know.

- Plan your route ahead of time

- Give yourself extra time for traffic or other delays

- If you are running late, call the interviewer to let them know

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastic Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.