Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pointer Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

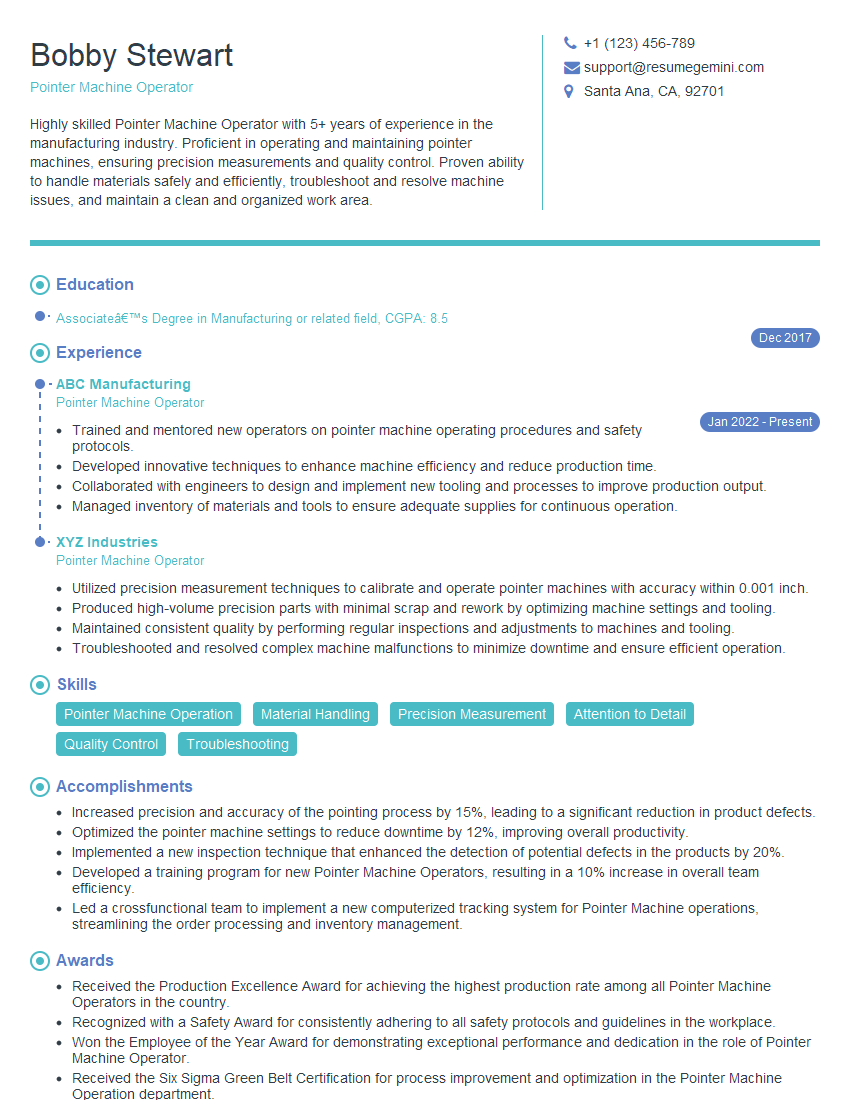

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pointer Machine Operator

1. What are the responsibilities of a Pointer Machine Operator?

As a Pointer Machine Operator, my primary responsibilities involve:

- Setting up and operating the Pointer Machine according to established procedures.

- Loading and unloading materials from the machine efficiently.

- Monitoring the machine’s operation and ensuring the production of high-quality products.

- Maintaining the machine and its components to prevent breakdowns and ensure optimal performance.

- Troubleshoot any issues that may arise during operation and resolve them promptly.

2. Explain the process of setting up a Pointer Machine for a new job.

- Obtain the job specifications: This includes details such as the material size, the desired pointer pattern, and any special requirements.

- Configure the machine settings: Adjust the machine’s speed, pressure, and pointer spacing based on the job specifications.

- Load the material: Place the material onto the machine’s table and secure it using clamps or a vacuum system.

- Test the setup: Run a short test cycle to ensure the machine is operating correctly and producing the desired results.

3. How do you ensure the accuracy and precision of the pointing process?

To ensure accuracy and precision, I follow these steps:

- Regularly calibrate the machine: This involves verifying and adjusting the machine’s settings using precision measurement tools.

- Use sharp and properly maintained pointers: Dull or damaged pointers can affect the quality of the pointing.

- Pay attention to the material’s grain and thickness: Different materials require different levels of pressure and pointer spacing to achieve optimal results.

- Monitor the process closely: I visually inspect the pointing pattern during operation to identify any deviations or inconsistencies.

4. What types of maintenance tasks are required for a Pointer Machine?

Regular maintenance is crucial to ensure the optimal performance and longevity of the Pointer Machine. I perform the following maintenance tasks:

- Daily cleaning: I clean the machine’s table, pointers, and other components to remove any debris or contaminants.

- Monthly lubrication: I lubricate moving parts such as bearings and gears to minimize friction and wear.

- Regular inspections: I check for any signs of wear or damage to the machine’s components, including belts, hoses, and electrical connections.

- Preventive maintenance: I perform scheduled maintenance tasks, such as replacing filters and tightening bolts, to prevent breakdowns and extend the machine’s lifespan.

5. How do you troubleshoot common problems that may occur during Pointer Machine operation?

Troubleshooting common problems is an essential aspect of my role. I follow a systematic approach to identify and resolve issues:

- Identify the problem: I observe the machine’s operation and identify any abnormal sounds, vibrations, or error messages.

- Check the machine settings: I verify that the settings are correct for the current job and make any necessary adjustments.

- Inspect the material: I check the material for any defects or inconsistencies that may be affecting the pointing process.

- Examine the pointers: I inspect the pointers for any signs of wear or damage and replace them if necessary.

6. What is the importance of safety when operating a Pointer Machine?

Safety is paramount when operating a Pointer Machine. I adhere to the following safety protocols:

- Wear appropriate personal protective equipment (PPE): This includes safety glasses, gloves, and earplugs.

- Keep the work area clean and organized: This helps prevent tripping hazards and promotes a safe working environment.

- Be aware of the machine’s moving parts: I maintain a safe distance and avoid reaching into the machine while it is operating.

- Follow lockout/tagout procedures: I ensure that the machine is properly isolated before performing any maintenance or repairs.

7. How do you handle variations in material thickness and hardness?

Variations in material thickness and hardness require adjustments to the machine’s settings and pointing process:

- For thicker materials: I increase the machine’s pressure and pointer spacing to ensure proper penetration.

- For harder materials: I use sharper pointers and increase the machine’s speed to achieve the desired pointing depth.

- For softer materials: I decrease the machine’s pressure and pointer spacing to avoid damaging the material.

8. What is the difference between single-pointing and multi-pointing?

- Single-pointing: Involves using a single pointer to create a series of individual points.

- Multi-pointing: Utilizes multiple pointers arranged in a pattern to create a continuous line or design.

9. How do you ensure the quality of the pointed products?

I follow these steps to ensure product quality:

- Visual inspection: I visually examine the pointed products for any imperfections or inconsistencies.

- Dimensional measurement: I use precision measuring tools to verify that the products meet the specified dimensions.

- Functional testing: I test the products to ensure they perform as intended.

10. How do you stay up-to-date with the latest advancements in Pointer Machine technology?

To stay current with industry advancements, I:

- Attend industry trade shows and conferences: This allows me to learn about new technologies and best practices.

- Read technical journals and articles: I stay informed about the latest research and developments in the field.

- Participate in online forums and discussion groups: I connect with other professionals and share knowledge about Pointer Machine technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pointer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pointer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pointer Machine Operators play a crucial role in the manufacturing process, operating complex pointer machines to produce intricate designs and patterns on a range of materials.

1. Machine Operation and Maintenance

The primary responsibility of a Pointer Machine Operator is to expertly operate and maintain pointer machines. This involves:

- Setting up and configuring the machine according to specified design requirements.

- Loading and unloading materials, ensuring proper alignment and positioning.

- Monitoring machine operations, adjusting settings as needed to achieve optimal results.

- Performing routine maintenance and troubleshooting to prevent breakdowns and ensure smooth functioning.

2. Interpretation of Design Specifications

Pointer Machine Operators must have a strong understanding of design specifications and technical drawings. They are responsible for:

- Interpreting complex designs and translating them into machine instructions.

- Identifying and rectifying any errors or inconsistencies in design specifications.

- Collaborating with engineers and designers to clarify requirements and ensure accurate execution.

3. Quality Control and Inspection

Pointer Machine Operators are responsible for maintaining high quality standards and ensuring the accuracy of produced parts. This involves:

- Inspecting finished products for defects, dimensional accuracy, and adherence to specifications.

- Identifying and rectifying any substandard products to meet quality standards.

- Maintaining detailed records of inspection results for quality assurance purposes.

4. Safety and Compliance

Pointer Machine Operators have a duty to maintain a safe work environment and comply with all applicable regulations and safety protocols. This includes:

- Following established safety procedures for machine operation and handling of materials.

- Wearing appropriate personal protective equipment (PPE) to minimize risk of injury.

- Maintaining a clean and organized work area to prevent accidents and hazards.

Interview Tips

Preparing for an interview for a Pointer Machine Operator position requires a combination of technical knowledge, practical experience, and effective communication skills.

1. Research the Company and Role

Thoroughly research the company’s products, services, and industry standing. In-depth knowledge of the specific role and its responsibilities will demonstrate your interest and preparedness.

- Review the company website, LinkedIn page, and any available press releases.

- Familiarize yourself with the job description and identify the key skills and experience required.

2. Highlight Relevant Experience

Focus on showcasing your relevant experience in operating pointer machines and handling similar responsibilities. Quantify your accomplishments with concrete examples and data.

- Emphasize your experience in setting up, calibrating, and maintaining pointer machines.

- Provide examples of successful projects where you interpreted design specifications and produced high-quality parts.

3. Demonstrate Technical Proficiency

Be well-versed in the technical aspects of pointer machine operation. Be prepared to answer questions about machine parameters, tooling, and safety procedures.

- Review common industry standards and best practices for pointer machine operation.

- Research different types of pointer machines and their capabilities.

4. Emphasize Quality and Safety

Highlight your commitment to quality control and safety. Explain how you ensure the accuracy and precision of produced parts while adhering to safety protocols.

- Share experiences where you identified and rectified quality defects.

- Discuss your knowledge of industry regulations and safety protocols related to pointer machine operation.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pointer Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.