Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rivet Sticker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

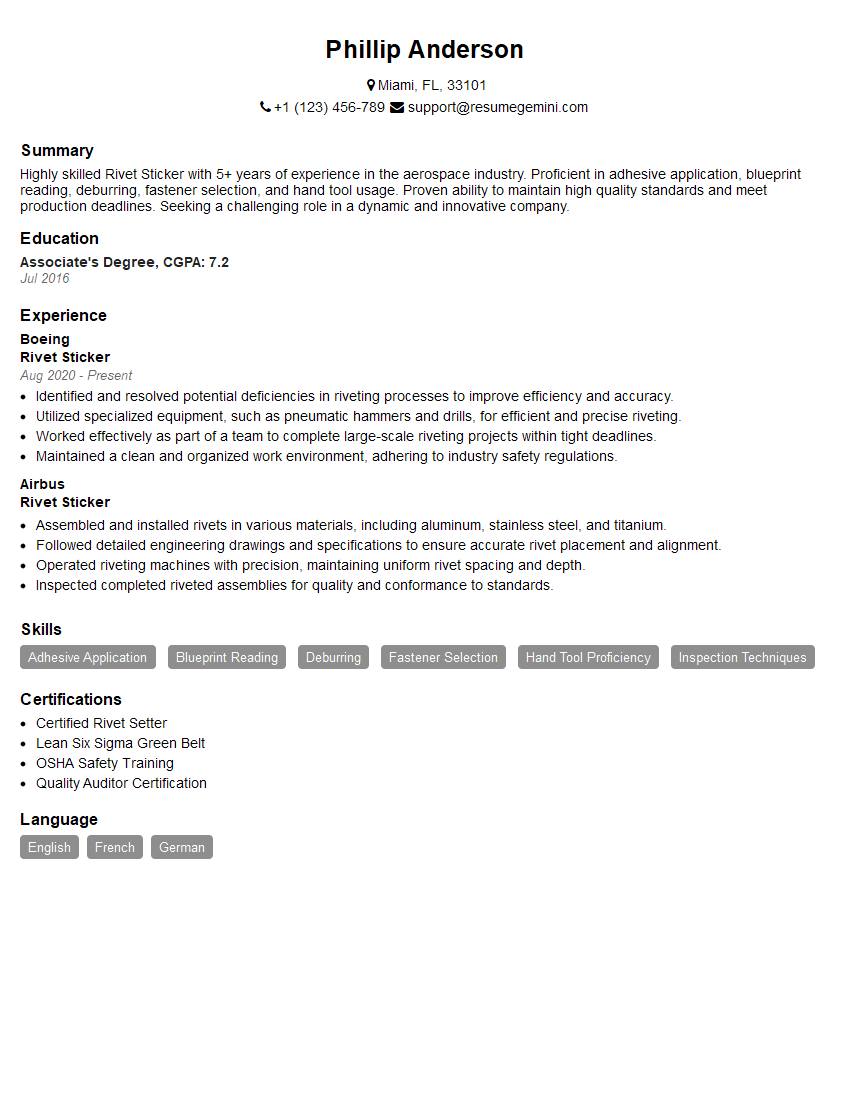

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rivet Sticker

1. What is the purpose of using a rivet gun?

A rivet gun is a power tool used to set rivets, which are permanent fasteners used to join two or more pieces of material together. Rivets are typically made of aluminum, steel, or stainless steel, and are available in a variety of sizes and shapes. A rivet gun uses compressed air or hydraulic pressure to drive the rivet into place, creating a strong and durable joint.

2. What are the different types of rivets?

There are several different types of rivets, including:

- Solid rivets: These are the most common type of rivet, and are made from a single piece of metal. They are usually installed using a rivet gun.

- Tubular rivets: These rivets are made from a hollow tube of metal, and are installed using a rivet gun. They are typically used in applications where a high level of strength is required.

- Split rivets: These rivets are made from two pieces of metal, which are joined together by a pin. They are installed using a rivet gun, and are typically used in applications where a high level of strength is required.

3. What are the different materials used to make rivets?

Rivets can be made from a variety of materials, including:

- Steel

- Aluminum

- Stainless steel

- Copper

- Brass

The material used to make a rivet will depend on the application in which it will be used. For example, steel rivets are commonly used in construction, while aluminum rivets are often used in aircraft construction.

4. What are the different sizes and shapes of rivets?

Rivets are available in a variety of sizes and shapes. The size of a rivet is determined by its diameter and length. The shape of a rivet can vary depending on the application in which it will be used. Some common rivet shapes include:

- Round

- Flat

- Oval

- Countersunk

- Domed

5. What are the different types of rivet guns?

There are several different types of rivet guns, including:

- Manual rivet guns: These rivet guns are operated by hand, and are typically used for small riveting jobs.

- Pneumatic rivet guns: These rivet guns are powered by compressed air, and are typically used for larger riveting jobs.

- Hydraulic rivet guns: These rivet guns are powered by hydraulic pressure, and are typically used for heavy-duty riveting jobs.

6. How do you choose the right rivet for a particular application?

The type of rivet that you choose for a particular application will depend on several factors, including:

- The materials that you are joining

- The thickness of the materials that you are joining

- The strength of the joint that you require

- The appearance of the joint

7. How do you install a rivet?

To install a rivet, you will need the following tools:

- A rivet gun

- The appropriate size and type of rivet

- A drill bit that is the same size as the diameter of the rivet

- A safety glasses

To install a rivet, follow these steps:

- Put on your safety glasses.

- Drill a hole in the materials that you are joining. The hole should be the same size as the diameter of the rivet.

- Insert the rivet into the hole. The head of the rivet should be flush with the surface of the material.

- Use the rivet gun to set the rivet. The rivet gun will squeeze the rivet, creating a strong and durable joint.

8. What are some common problems that you may encounter when installing rivets?

Some common problems that you may encounter when installing rivets include:

- The rivet is too large or too small for the hole.

- The rivet is not properly seated in the hole.

- The rivet is not properly set.

- The rivet breaks.

If you encounter any of these problems, you can try the following:

- Use a different size or type of rivet.

- Make sure that the rivet is properly seated in the hole.

- Use a different rivet gun.

- Replace the rivet.

9. What are some safety tips for installing rivets?

When installing rivets, it is important to follow these safety tips:

- Always wear safety glasses.

- Never point the rivet gun at anyone.

- Keep the rivet gun in good working condition.

- Use the proper size and type of rivet for the job.

- Make sure that the rivet is properly seated in the hole.

- Use a firm grip when setting the rivet.

- Never attempt to remove a rivet that has already been set.

10. Is there anything else I can help you with today?

I hope these questions have been helpful. If you have any other questions, please feel free to ask.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rivet Sticker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rivet Sticker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rivet Sticker is responsible for adhering rivets to various surfaces during the construction and repair of aircraft and other structures.

1. Adhering Rivets

The primary responsibility of a Rivet Sticker is to attach rivets to designated locations on aircraft or other structures using specialized tools and equipment.

- Accurately place rivets into pre-drilled holes

- Operate riveting machines to secure rivets in place

2. Inspecting Surfaces

Before adhering rivets, the Rivet Sticker inspects the work surface to ensure it is clean, free of debris, and ready for rivet placement.

- Examine surfaces for damage or imperfections

- Clean surfaces using approved methods

3. Maintaining Equipment

Rivet Stickers are responsible for maintaining the equipment they use, including riveting machines and other tools.

- Clean and lubricate equipment regularly

- Inspect equipment for malfunctions or damage

4. Following Safety Procedures

Rivet Stickers must adhere to strict safety protocols to minimize the risk of injury or damage to equipment.

- Wear appropriate personal protective equipment (PPE)

- Follow established work procedures and safety regulations

Interview Tips

To prepare for an interview for a Rivet Sticker position, candidates should focus on highlighting their technical skills, attention to detail, and safety awareness.

1. Research the Industry

Familiarize yourself with the industry and the specific company you are interviewing with. This demonstrates your enthusiasm and shows that you have taken the time to learn about the opportunity.

- Research the company’s history, products, and services

- Understand the current trends and challenges in the industry

2. Practice your Skills

Before the interview, practice operating riveting machines and other tools you may be required to use. This will boost your confidence and demonstrate your proficiency.

- Set up a practice area to simulate the work environment

- Practice adhering rivets accurately and securely

3. Prepare for Technical Questions

Be prepared to answer questions about your technical abilities and knowledge of riveting processes. Review common riveting techniques, materials, and safety procedures.

- Study different types of rivets and their applications

- Research industry standards and best practices for riveting

4. Emphasize Safety

Safety is paramount in the role of a Rivet Sticker. Highlight your commitment to following safety protocols and maintaining a safe work environment.

- Describe your experience with identifying and mitigating hazards

- Explain how you prioritize safety in your work

5. Show Attention to Detail

Attention to detail is crucial for a Rivet Sticker. In the interview, demonstrate your ability to work accurately and inspect surfaces thoroughly.

- Provide examples of your attention to detail in previous roles

- Explain how you ensure accuracy in your work

Next Step:

Now that you’re armed with the knowledge of Rivet Sticker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rivet Sticker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini