Are you gearing up for a career in Scarfing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Scarfing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

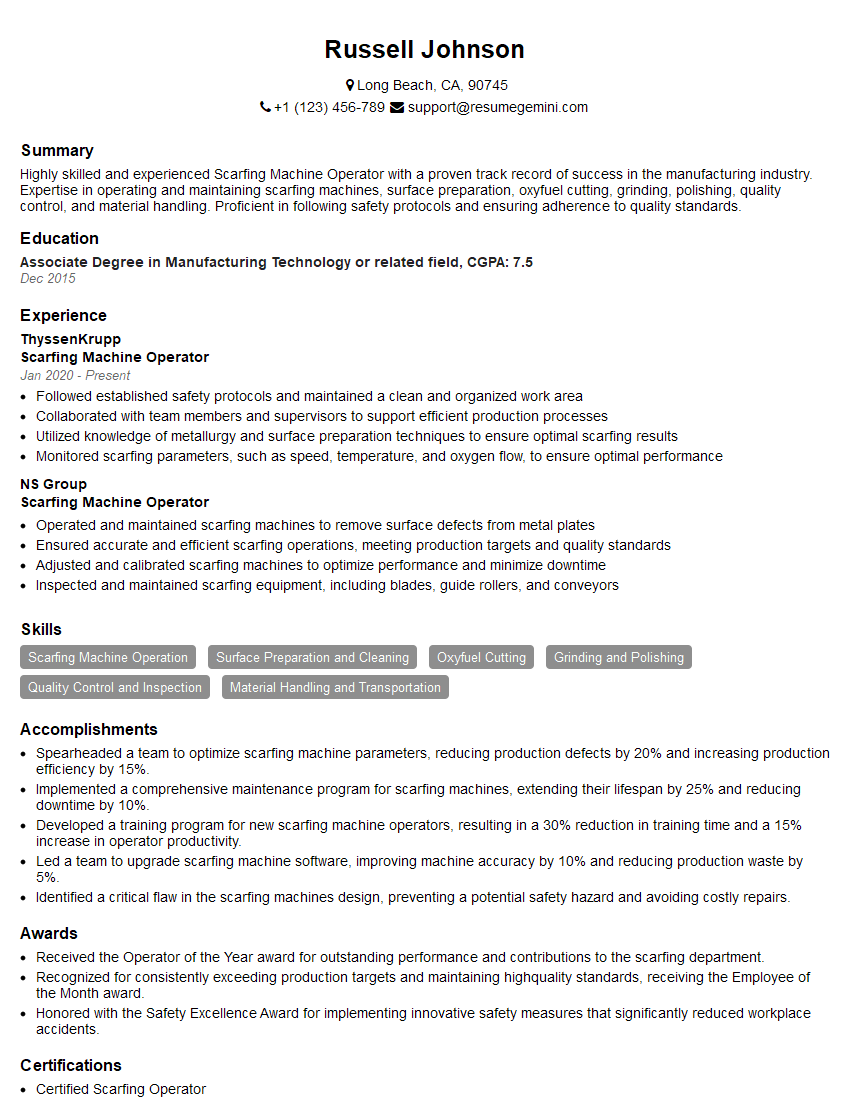

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scarfing Machine Operator

1. What are the key operating principles of a scarfing machine?

- Understanding of the oxy-fuel gas cutting process

- Knowledge of the machine’s mechanical and electrical systems

- Ability to control and manipulate the cutting torch accurately

2. Describe the different types of scarfing tips and when they are used.

- Round tip: General-purpose tip for most scarfing applications

- Pointed tip: For narrower cuts and precision work

- Square tip: For wider cuts and removing large amounts of material

3. How do you maintain the scarfing machine to ensure optimal performance?

- Regular cleaning and inspection of the torch and cutting head

- Replacement of worn or damaged parts as needed

- Calibration and adjustment of the machine’s settings

4. Explain the safety precautions that must be followed when operating a scarfing machine.

- Wearing proper personal protective equipment (PPE)

- Ensuring adequate ventilation in the work area

- Handling and storing oxygen and fuel gases safely

5. How do you determine the appropriate cutting speed and oxygen pressure for different materials?

- Reference to manufacturer’s specifications or industry standards

- Trial and error to achieve optimal results

- Consideration of the material thickness and composition

6. What are the different types of scarfing defects and how can they be prevented?

- Gouging: Caused by excessive heat or improper torch angle

- Undercut: Occurs when the torch is too far from the workpiece

- Excessive slag: Indicates insufficient oxygen pressure

7. How do you troubleshoot common scarfing machine problems?

- Loss of cutting power: Check for clogged tips or gas supply issues

- Excessive smoke: Adjust oxygen pressure or check for contaminated gases

- Machine overheating: Ensure proper cooling system functioning

8. What techniques can be used to improve the efficiency of scarfing operations?

- Optimizing cutting parameters (speed, oxygen pressure, torch angle)

- Minimizing workpiece movement during cutting

- Utilizing automation and robotics for repetitive tasks

9. Describe the quality assurance procedures involved in scarfing operations.

- Visual inspection for defects and dimensional accuracy

- Nondestructive testing (NDT) for internal flaws

- Compliance with industry standards and customer specifications

10. How do you stay updated with the latest advancements in scarfing technology?

- Attend industry conferences and training sessions

- Read trade publications and technical articles

- Consult with equipment manufacturers and suppliers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scarfing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scarfing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Scarfing Machine Operators are responsible for operating and maintaining scarfing machines, which are used to remove surface defects from metal. They work in a variety of industries, including steel mills, foundries, and fabrication shops.

1. Operate Scarfing Machines

Scarfing Machine Operators must be able to operate scarfing machines safely and efficiently. They must also be able to adjust the machine settings to accommodate different types of metal and defects.

- Load and unload metal into the scarfing machine

- Operate the scarfing machine to remove defects from metal

- Adjust the machine settings to accommodate different types of metal and defects

2. Maintain Scarfing Machines

Scarfing Machine Operators are also responsible for maintaining their machines. They must be able to identify and troubleshoot problems, and make necessary repairs.

- Clean and lubricate the scarfing machine

- Inspect the scarfing machine for wear and tear

- Troubleshoot and repair problems with the scarfing machine

3. Quality Control

Scarfing Machine Operators must be able to inspect the quality of their work. They must be able to identify and correct any defects in the metal.

- Inspect the metal after scarfing to ensure that all defects have been removed

- Identify and correct any defects in the metal

4. Safety

Scarfing Machine Operators must be aware of the safety hazards associated with their work. They must be able to follow safety procedures and wear appropriate protective gear.

- Follow safety procedures when operating the scarfing machine

- Wear appropriate protective gear, such as gloves, safety glasses, and a hard hat

Interview Tips

Preparing for a Scarfing Machine Operator interview can be daunting, but with the right preparation, you can increase your chances of landing the job. Here are a few tips:

1. Research the Company

Before you go to your interview, take some time to research the company. This will help you learn about their culture, values, and products or services. You can find this information on the company website, social media pages, and news articles.

- Visit the company website

- Follow the company on social media

- Read news articles about the company

2. Know Your Resume

Make sure you know your resume inside and out. This means being able to talk about your skills, experience, and qualifications. You should also be prepared to answer questions about your resume, such as why you are interested in the job and why you think you are the best candidate.

- Review your resume carefully

- Be prepared to talk about your skills, experience, and qualifications

- Prepare answers to common interview questions

3. Practice Your Answers

Once you have prepared your answers, it is important to practice them. This will help you feel more confident and prepared during the interview. You can practice with a friend, family member, or career counselor.

- Practice answering common interview questions

- Practice with a friend, family member, or career counselor

- Record yourself practicing so you can see how you come across

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job. You should also make sure your hair is neat and your shoes are polished.

- Wear clean, pressed clothes

- Dress appropriately for the job

- Make sure your hair is neat and your shoes are polished

5. Be Yourself

The most important thing is to be yourself during your interview. Employers want to know who you are and what you are like to work with. So be honest, be yourself, and let your personality shine through.

- Be honest

- Be yourself

- Let your personality shine through

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Scarfing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!