Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Trimmer Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

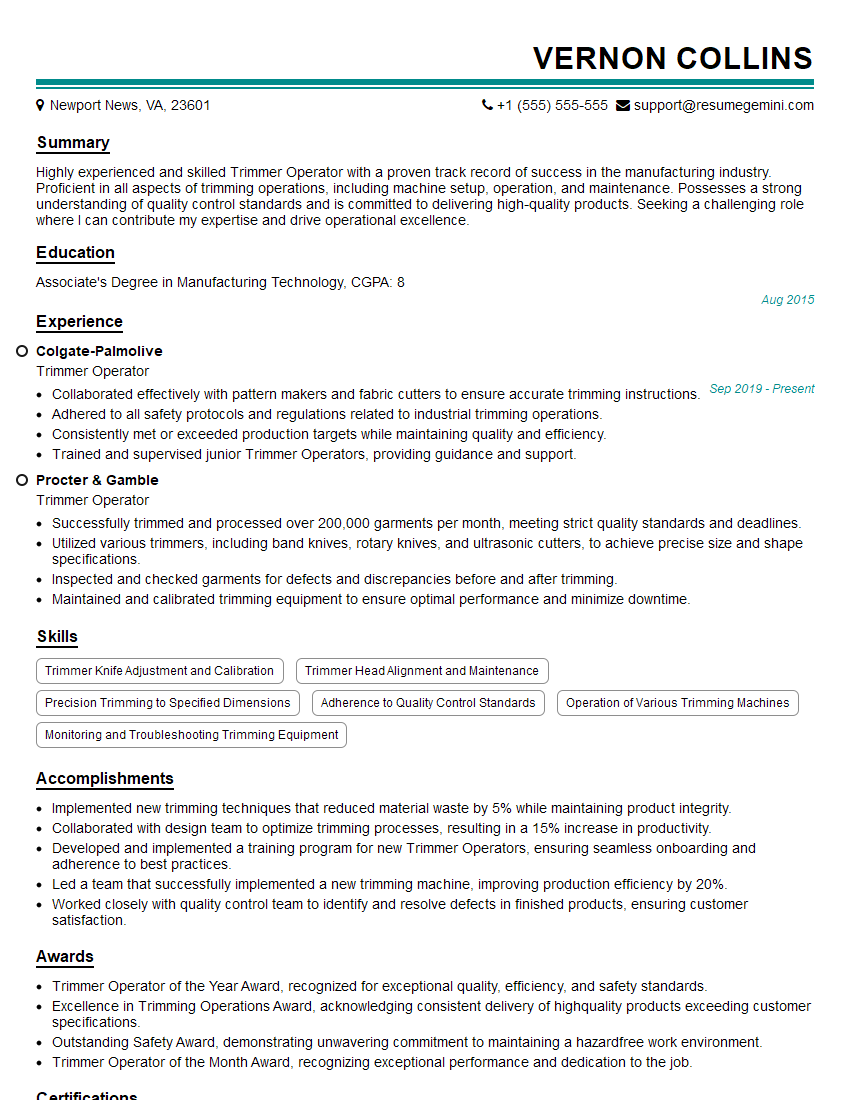

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trimmer Operator

1. Describe the process of trimming and finishing knitwear products?

The process of trimming and finishing knitwear products involves several steps:

- Inspecting the garments: Checking for any defects or imperfections.

- Cutting loose threads: Removing any excess threads or yarn that may have come loose during the knitting process.

- Trimming excess fabric: Cutting away any excess fabric around the edges of the garment, such as around the seams or neckline.

- Finishing the edges: Using various techniques such as overlocking, hemming, or serging to reinforce the edges and prevent fraying.

- Pressing and steaming: Using heat and steam to shape and smooth the garment, giving it a professional finish.

2. What types of trimming machines are used in the industry?

Knitting machines

- Flat knitting machines

- Circular knitting machines

- Warp knitting machines

Trimming machines

- Band knife trimming machines

- Rotary knife trimming machines

- Laser trimming machines

3. What factors should be considered when selecting the right trimming method?

When selecting the right trimming method for a specific knitwear product, several factors should be taken into account:

- Fabric type: The type of fabric, its thickness, and its stretchiness will influence the choice of trimming technique.

- Desired finish: The desired look and feel of the finished garment will dictate the specific trimming method used.

- Production volume: The scale of production and the required speed of trimming will impact the choice of machine and method.

- Cost considerations: The cost of the equipment, labor, and materials involved in each trimming method should be considered.

4. How do you ensure the quality of trimmed knitwear products?

Ensuring the quality of trimmed knitwear products involves several steps:

- Regular machine maintenance: Keeping trimming machines well-maintained and calibrated ensures accurate and consistent trimming.

- Quality control checks: Implementing quality control checks throughout the trimming process, including inspecting garments at various stages for defects.

- Operator training: Providing thorough training to operators on proper trimming techniques and equipment handling.

- Process standardization: Establishing standardized trimming procedures and guidelines to maintain consistency across products.

5. What are the common challenges faced in the trimming process and how can they be overcome?

Common challenges in the trimming process include:

- Fabric puckering or distortion: This can be minimized by using the appropriate trimming technique and tension settings for the specific fabric.

- Uneven trimming: Ensuring proper machine calibration and operator training can help achieve consistent and even trimming.

- Trimming too close to the seam: Careful handling and attention to detail are essential to avoid trimming too close to the seam, which can weaken the garment.

- Excessive thread or yarn removal: Proper machine adjustment and operator training can prevent excessive removal of threads or yarn, maintaining the integrity of the garment.

6. What safety precautions should be followed when operating trimming machines?

- Wear appropriate safety gear: Including safety glasses, gloves, and earplugs.

- Keep work area organized: To prevent tripping hazards and ensure a safe working environment.

- Follow lockout/tagout procedures: When servicing or cleaning machines, to prevent accidental startup.

- Be aware of sharp blades: Handle knives and other sharp tools with care and keep them properly guarded.

- Report any malfunctions or concerns: Promptly report any issues with machines or equipment to ensure timely maintenance and repairs.

7. Describe your experience in troubleshooting and resolving issues with trimming machines.

In my previous role, I was responsible for troubleshooting and resolving various issues with trimming machines, including:

- Blade dullness: Identified and replaced dull blades to ensure clean and precise trimming.

- Tension problems: Adjusted tension settings to prevent fabric puckering or uneven trimming.

- Motor malfunctions: Collaborated with maintenance technicians to diagnose and repair motor issues.

- Electrical faults: Followed electrical diagrams and used diagnostic tools to identify and resolve electrical problems.

- Software errors: Troubleshooted software issues and performed necessary updates or reprogramming.

8. How do you stay updated with the latest advancements in trimming technology?

- Attending industry conferences and exhibitions: To learn about new machines, techniques, and best practices.

- Reading industry publications and online resources: To stay informed about technological developments and trends.

- Participating in training and workshops: To enhance skills and knowledge on new trimming technologies.

- Networking with industry professionals: To exchange ideas and learn about innovative approaches.

9. How do you handle working in a fast-paced production environment?

- Prioritizing tasks: Identifying the most critical tasks and allocating time accordingly.

- Maintaining focus and concentration: Staying focused on the task at hand to avoid errors and ensure accuracy.

- Communicating effectively: Coordinating with colleagues and supervisors to ensure smooth workflow and timely completion of projects.

- Utilizing time management techniques: Implementing strategies such as the Pomodoro technique to optimize productivity.

- Remaining calm under pressure: Maintaining composure and making sound decisions even in stressful situations.

10. Why are you interested in this Trimmer Operator position?

I am eager to join your organization as a Trimmer Operator because:

- My passion for textiles and garment production: I have always been fascinated by the intricate processes involved in creating knitwear products.

- My technical skills and experience: My proven proficiency in trimming and finishing techniques aligns well with the requirements of this role.

- My commitment to quality and precision: I take pride in delivering high-quality products and am meticulous in my attention to detail.

- My eagerness to learn and grow: I am keen on expanding my knowledge and skills in the field of trimming and am eager to contribute to your team.

- My enthusiasm for working in a fast-paced environment: I thrive in dynamic and challenging work settings and am confident in my ability to perform efficiently under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trimmer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trimmer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

A Trimmer Operator is responsible for a variety of tasks related to trimming and finishing products across various industries, ranging from manufacturing to retail. Their role involves performing repetitive operations using specialized equipment to achieve specific quality standards.

1. Trimming and Finishing:

The primary responsibility of a Trimmer Operator is to trim excess material and finish products to meet specifications. This may involve using various tools and equipment, including knives, scissors, and trimmers.

- Precisely cut or trim materials according to specified dimensions and tolerances.

- Remove burrs, sharp edges, or imperfections to improve product aesthetics and functionality.

2. Quality Control:

Trimmer Operators play a crucial role in ensuring product quality. They are responsible for inspecting and verifying the accuracy and completeness of trimmed products.

- Inspect products for defects, inconsistencies, or deviations from specifications.

- Identify and correct errors, ensuring that products meet quality standards.

3. Equipment Operation and Maintenance:

Trimmer Operators are proficient in operating and maintaining trimming equipment. This includes performing routine cleaning, adjusting settings, and troubleshooting minor issues.

- Operate trimming machines efficiently and safely, following established procedures.

- Perform basic equipment maintenance and repairs to minimize downtime and ensure optimal performance.

4. Production Support:

Trimmer Operators contribute to the overall production process by maintaining a consistent work pace and supporting other team members.

- Work in a fast-paced environment, meeting production targets and deadlines.

- Assist with material handling, setup, and other tasks as required.

Interview Preparation Tips:

To ace the interview for a Trimmer Operator position, it’s crucial to be well-prepared and demonstrate your skills and experience. Here are some preparation tips to help you succeed:

1. Research the Company and Position:

Take the time to learn about the company’s background, values, and specific requirements for the Trimmer Operator role. This will help you tailor your responses and highlight your qualifications.

2. Practice Answering Common Interview Questions:

Prepare for questions related to your experience, skills, and knowledge of trimming operations and equipment. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Showcase Your Attention to Detail and Accuracy:

Trimmer Operators must have a keen eye for detail and high precision in their work. Highlight your ability to identify and correct errors, and provide examples of your accuracy and attention to quality.

4. Emphasize Your Equipment Proficiency:

Familiarity with trimming equipment is essential for this role. Describe your experience operating different types of trimmers, and explain how you ensure their optimal performance and efficiency.

5. Highlight Your Communication and Teamwork Skills:

Trimmer Operators often work in production environments with other team members. Demonstrate your ability to communicate effectively, collaborate with others, and contribute to a cohesive work atmosphere.

6. Prepare Questions for the Interviewer:

Asking intelligent questions at the end of the interview shows your interest and engagement. Prepare questions related to the company’s production process, safety procedures, or opportunities for professional development.

Next Step:

Now that you’re armed with the knowledge of Trimmer Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Trimmer Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini