Feeling lost in a sea of interview questions? Landed that dream interview for Torsion Spring Coiling Machine Setter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Torsion Spring Coiling Machine Setter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

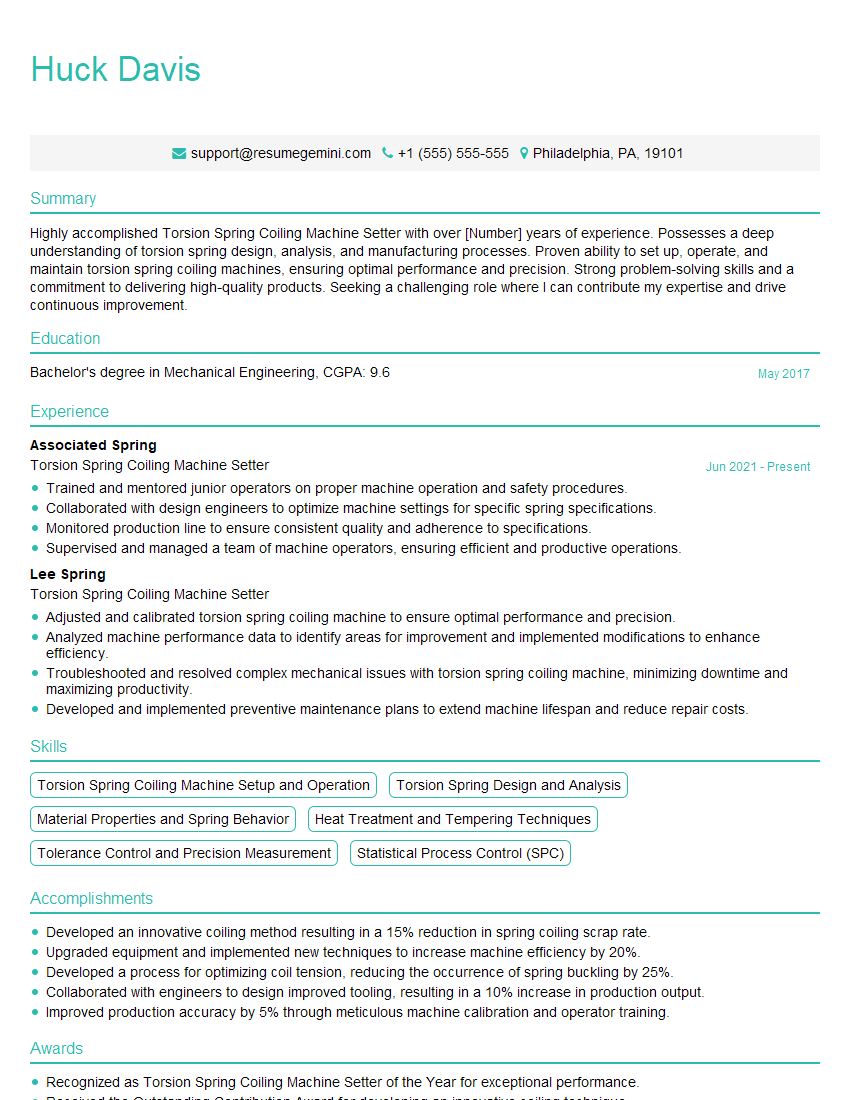

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Torsion Spring Coiling Machine Setter

1. What are the key responsibilities of a Torsion Spring Coiling Machine Setter?

As a Torsion Spring Coiling Machine Setter, my key responsibilities include:

- Setting up and operating torsion spring coiling machines

- Adjusting machine settings to produce springs that meet specifications

- Troubleshooting and repairing machine malfunctions

- Maintaining a clean and organized work area

- Following safety procedures

2. What are the different types of torsion springs?

Compression springs

- Used to store energy and release it when compressed

- Typically made from round wire

- Can be open or closed

Extension springs

- Used to store energy and release it when extended

- Typically made from round wire

- Can be open or closed

Torsion springs

- Used to store energy and release it when twisted

- Typically made from flat wire

- Can be open or closed

3. What are the factors that affect the performance of a torsion spring?

The following factors can affect the performance of a torsion spring:

- Material

- Wire diameter

- Coil diameter

- Number of coils

- Pitch

- End configuration

4. What are the common problems that can occur with torsion springs?

The following are some common problems that can occur with torsion springs:

- Spring breakage

- Spring distortion

- Spring fatigue

- Spring corrosion

5. What are the safety precautions that should be taken when working with torsion springs?

The following safety precautions should be taken when working with torsion springs:

- Wear safety glasses

- Wear gloves

- Use caution when handling springs

- Do not attempt to repair or modify springs

- Follow all manufacturer’s instructions

6. What are the different types of materials used to make torsion springs?

The following are some of the most common materials used to make torsion springs:

- Steel

- Stainless steel

- Brass

- Copper

- Aluminum

7. What are the different types of end configurations for torsion springs?

The following are some of the most common end configurations for torsion springs:

- Open ends

- Closed ends

- Hooked ends

- Looped ends

- Threaded ends

8. What is the difference between a right-hand and a left-hand torsion spring?

A right-hand torsion spring is wound in a clockwise direction, while a left-hand torsion spring is wound in a counterclockwise direction.

9. What is the purpose of a torsion spring?

Torsion springs are used to store energy and release it when twisted. They are commonly used in a variety of applications, such as watches, clocks, and toys.

10. What is the difference between a compression spring and a torsion spring?

Compression springs are designed to resist compression, while torsion springs are designed to resist twisting. Compression springs are typically used to store energy and release it when compressed, while torsion springs are typically used to store energy and release it when twisted.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Torsion Spring Coiling Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Torsion Spring Coiling Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Torsion Spring Coiling Machine Setter plays a crucial role in ensuring the efficient and precise production of torsion springs, which are widely used in various industries. Their key job responsibilities encompass:

1. Machine Setup and Calibration

Setting up and calibrating torsion spring coiling machines to meet specific spring design specifications, including wire diameter, coil diameter, pitch, and length.

- Installing and adjusting tooling, such as mandrels, coiling heads, and tensioning devices, to achieve desired spring dimensions.

- Programming machine parameters, including speed, tension, and dwell time, to optimize spring performance.

2. Production Monitoring and Quality Control

Monitoring the coiling process and making necessary adjustments to ensure consistent spring quality and adherence to specifications.

- Inspecting springs for defects, such as burrs, cracks, or dimensional inaccuracies, using precision measuring tools and gauges.

- Performing periodic maintenance on machines and tooling to minimize downtime and ensure smooth operation.

3. Troubleshooting and Problem Solving

Identifying and resolving machine malfunctions, spring defects, or production issues promptly and effectively.

- Analyzing spring dimensions, machine settings, and material properties to determine the root cause of problems.

- Implementing corrective actions, such as adjusting machine parameters, replacing worn components, or modifying spring designs, to restore production efficiency.

4. Continuous Improvement and Training

Seeking opportunities to improve processes, reduce waste, and enhance machine performance.

- Identifying areas for improvement through data analysis, feedback from downstream processes, or industry best practices.

- Participating in training programs to stay abreast of advancements in torsion spring coiling technology and techniques.

Interview Tips

To ace an interview for a Torsion Spring Coiling Machine Setter position, candidates should focus on showcasing their technical skills, problem-solving abilities, and commitment to quality.

1. Research the Company and Position

Thoroughly research the company, its products, and the specific requirements of the Torsion Spring Coiling Machine Setter role. This will demonstrate your interest in the position and help you tailor your answers to the interviewer’s expectations.

2. Practice Common Interview Questions

Prepare for common interview questions related to your experience in torsion spring coiling, machine setup, quality control, and troubleshooting. Practice answering these questions clearly and concisely, showcasing your technical knowledge and problem-solving approach.

3. Highlight Your Technical Expertise

Emphasize your understanding of torsion spring design, machine operation, and quality control standards. Provide specific examples of how you have used your skills to improve production efficiency or resolve technical issues in previous roles.

4. Showcase Your Troubleshooting Abilities

Describe instances where you successfully diagnosed and resolved complex problems related to torsion spring coiling machines or spring defects. Explain the steps you took to identify the root cause and implement effective solutions.

5. Discuss Your Commitment to Quality

Demonstrate your commitment to producing high-quality torsion springs by highlighting your attention to detail, adherence to specifications, and involvement in continuous improvement initiatives.

6. Ask Insightful Questions

During the interview, ask thoughtful questions about the company’s production processes, quality standards, and opportunities for professional development. This shows your engagement and interest in the role and the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Torsion Spring Coiling Machine Setter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!