Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wire Mesh Knitter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

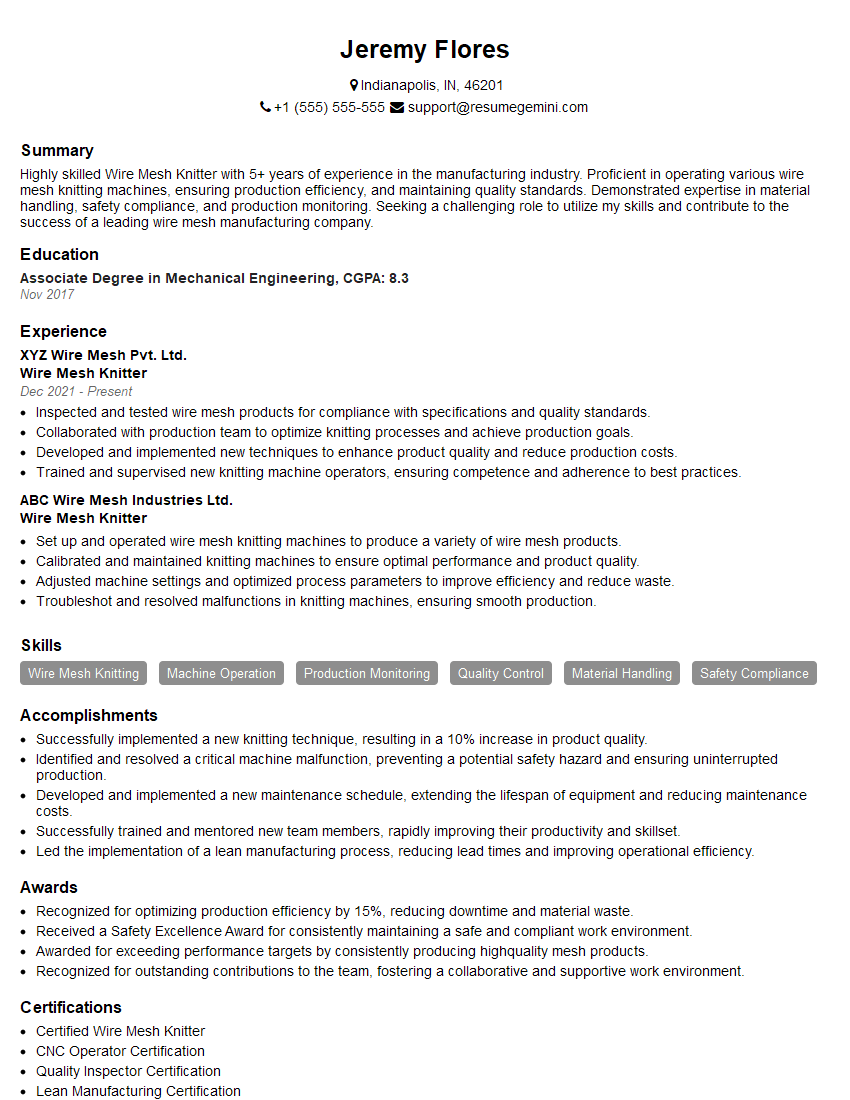

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Mesh Knitter

1. What are the essential properties of wire used for mesh knitting?

- Tensile strength: The wire must withstand the forces involved in knitting without breaking.

- Ductility: The wire must be able to bend without breaking, allowing for the formation of loops.

- Weldability: The wire must be capable of being welded to form strong joints between individual loops.

- Corrosion resistance: The wire should resist corrosion to maintain the integrity of the mesh in various applications.

2. Describe the different types of wire mesh knit patterns and their applications.

Plain weave

- Simple and versatile pattern formed by alternating rows of alternating loops.

- Applications: Filters, screens, fencing.

Twill weave

- More complex pattern with diagonal ribs.

- Applications: Conveyor belts, automotive parts.

Dutch weave

- Open and airy pattern with skip stitches.

- Applications: Architectural facades, decorative elements.

3. How do you determine the mesh size and wire diameter for a specific application?

- Consider the intended use and required filtration, separation, or other properties.

- Calculate the mesh opening size based on the desired particle size or flow rate.

- Determine the wire diameter based on the required strength, flexibility, and corrosion resistance.

- Refer to standard mesh size charts for guidance.

4. What is the role of heat treatment in wire mesh knitting?

- Increases the strength and hardness of the wire.

- Improves the wire’s resistance to corrosion and wear.

- Can alter the wire’s ductility and weldability.

- Heat treatment parameters vary depending on the specific wire material and desired properties.

5. Explain the process of wire mesh annealing.

- Controlled heating and cooling of the wire to relieve internal stresses and increase ductility.

- Involves raising the wire to a specific temperature and holding it for a period of time.

- Slow cooling allows the wire structure to rearrange, reducing brittleness.

- Annealing improves the wire’s flexibility and weldability.

6. What are the safety precautions to consider while operating a wire mesh knitting machine?

- Wear appropriate protective gear, including gloves, safety glasses, and earplugs.

- Inspect the machine regularly and keep it well-maintained.

- Follow proper wire handling and storage procedures.

- Be aware of moving parts and avoid entrapment.

- Receive proper training and follow established safety protocols.

7. Describe the different types of knitting needles used in wire mesh knitting machines.

- Single-hook needles: Form basic loops.

- Multi-hook needles: Create more complex patterns.

- Compound needles: Combine features of both single-hook and multi-hook needles.

- Sinker bars: Aid in loop formation and mesh stability.

8. How do you troubleshoot common problems encountered during wire mesh knitting?

- Broken wires: Check wire quality, tension, and machine settings.

- Missed stitches: Adjust needle alignment, tension, or knitting speed.

- Mesh distortion: Ensure proper machine calibration and tension.

- Welding defects: Inspect welding parameters, wire preparation, and contact surfaces.

- Corrosion: Use corrosion-resistant wire or apply protective coatings.

9. Explain the importance of quality control in wire mesh knitting.

- Ensures consistency, durability, and performance of the mesh.

- Includes inspections of wire quality, mesh dimensions, weld strength, and overall appearance.

- Non-destructive testing methods, such as ultrasonic testing, can be employed for quality assessment.

- Quality control measures help meet customer specifications and industry standards.

10. What are the emerging trends and advancements in wire mesh knitting technology?

- Computer-aided design and manufacturing (CAD/CAM) systems for precise mesh creation.

- Automated knitting machines for improved efficiency and accuracy.

- Development of new materials and alloys for enhanced performance.

- Smart meshes with integrated sensors for various applications.

- Research on advanced weaving techniques and novel mesh structures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Mesh Knitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Mesh Knitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wire Mesh Knitters perform a crucial role in the manufacturing industry by operating specialized machinery to create wire mesh products. These professionals possess a unique set of skills in wire mesh knitting, ensuring the production of high-quality and durable materials for various applications.

1. Wire Mesh Production

The primary responsibility of Wire Mesh Knitters is to operate and maintain wire mesh knitting machines. They must have a thorough understanding of the knitting process, including the different types of knitted meshes and the parameters that influence their properties.

- Set up and operate knitting machines to produce wire mesh of specified dimensions and patterns.

- Monitor and adjust machine settings to ensure proper knitting tension, stitch density, and mesh quality.

2. Machine Maintenance

Wire Mesh Knitters are responsible for maintaining the knitting machines they operate in optimal condition. This includes regular cleaning, lubrication, and minor repairs to prevent breakdowns and ensure smooth operation.

- Perform routine maintenance tasks, such as cleaning, oiling, and replacing worn parts on knitting machines.

- Identify and troubleshoot machine malfunctions, and take corrective actions to minimize downtime.

3. Quality Control

Wire Mesh Knitters play a vital role in ensuring the quality of the wire mesh products produced. They inspect the finished mesh for defects, such as broken wires, missed stitches, and uneven patterns.

- Inspect wire mesh for defects, such as broken wires, missed stitches, or uneven patterns.

- Reject or rework non-conforming mesh to maintain product quality standards.

4. Material Handling

Wire Mesh Knitters are responsible for handling and storing raw materials and finished products in a safe and organized manner. This involves loading and unloading materials, transporting mesh coils and rolls, and maintaining proper inventory levels.

- Load and unload wire spools and finished wire mesh products.

- Maintain proper inventory levels of raw materials and finished products.

Interview Tips

To ace the interview for a Wire Mesh Knitter position, it is important to prepare thoroughly and demonstrate your skills and experience in the following areas:

1. Technical Expertise

Interviewers will be interested in your knowledge of wire mesh knitting machines, the types of knitted meshes, and the quality standards for these products. Highlight your understanding of the knitting process, including the parameters that influence the properties of the mesh.

- Review the basics of wire mesh knitting and the different types of knitted meshes.

- Research the industry standards and specifications for wire mesh products.

2. Practical Experience

Employers value candidates who have hands-on experience operating wire mesh knitting machines. Emphasize your experience in setting up and running machines, troubleshooting problems, and maintaining a clean and efficient work environment.

- Quantify your accomplishments and provide specific examples of your productivity and efficiency.

- Be prepared to discuss your experience in using specific types of knitting machines.

3. Quality Control Mindset

Wire Mesh Knitters are expected to be quality-conscious and committed to producing high-quality products. Highlight your attention to detail and your ability to identify and resolve defects in the wire mesh.

- Describe your understanding of quality control processes and your commitment to meeting industry standards.

- Share examples of how you have contributed to improving product quality in previous roles.

4. Safety Awareness

Working with wire mesh knitting machines can involve potential hazards. Demonstrate your awareness of safety protocols and your commitment to maintaining a safe work environment.

- Review the safety guidelines and regulations for operating wire mesh knitting machines.

- Be prepared to discuss your experience in following safety procedures and working in a safe manner.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wire Mesh Knitter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wire Mesh Knitter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.