Feeling lost in a sea of interview questions? Landed that dream interview for Electrotyper Apprentice but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Electrotyper Apprentice interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

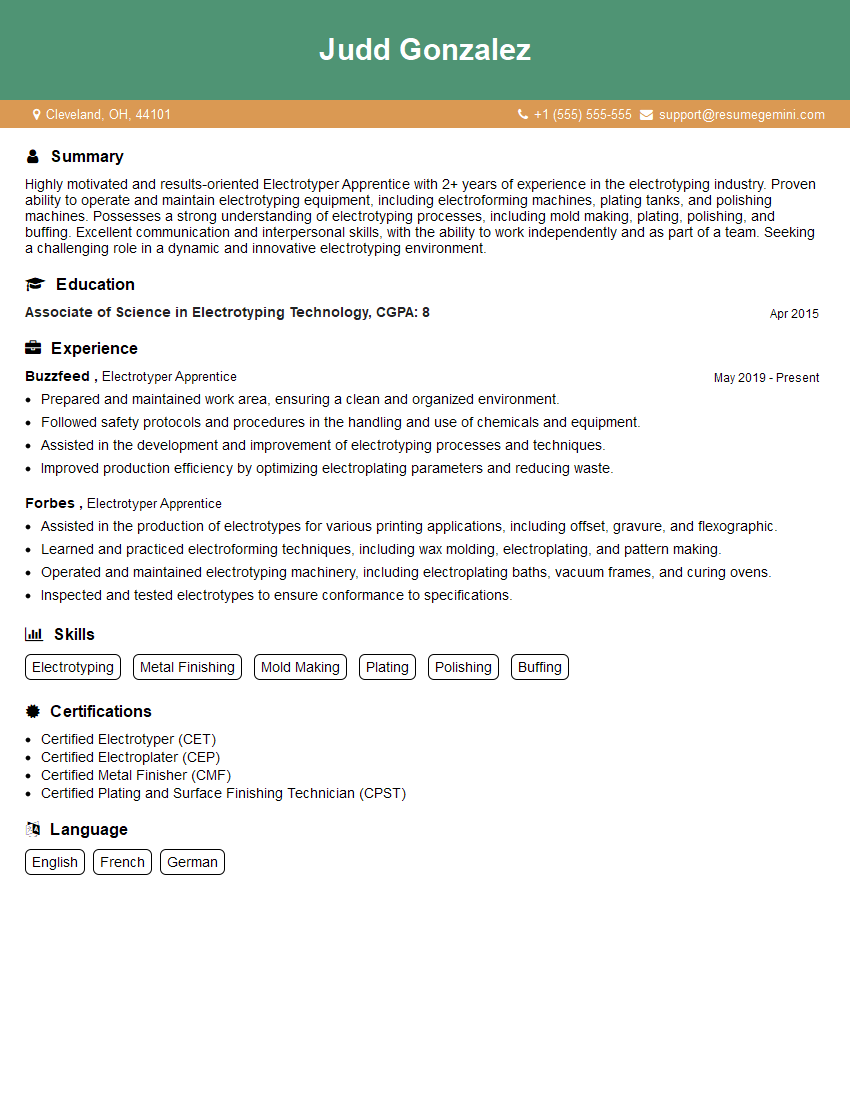

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrotyper Apprentice

1. Describe the electrotyping process.

Electrotyping is a process of creating a metal replica of an object by electroplating. The object to be copied is first coated with a conductive material, such as graphite or silver paint. The object is then placed in a bath of electrolyte, and an electric current is passed through the bath. The metal ions in the electrolyte are deposited on the conductive coating, creating a metal replica of the object.

2. What are the different types of electrotyping baths?

Acid baths

- Acid baths are the most common type of electrotyping bath. They are made up of a strong acid, such as sulfuric acid or hydrochloric acid, and a metal salt, such as copper sulfate or nickel sulfate.

- Acid baths produce a hard, durable metal coating.

Alkaline baths

- Alkaline baths are less common than acid baths. They are made up of a strong base, such as sodium hydroxide or potassium hydroxide, and a metal salt, such as copper sulfate or nickel sulfate.

- Alkaline baths produce a softer, more ductile metal coating.

3. What are the factors that affect the thickness of the electroplated coating?

- The current density

- The temperature of the bath

- The concentration of the metal salt in the bath

- The time of electroplating

4. What are the different applications of electrotyping?

- Electrotyping is used to create metal replicas of objects for a variety of purposes, including:

- Jewelry making

- Art and sculpture

- Industrial applications

- Medical applications

5. What are the safety precautions that must be taken when working with electrotyping baths?

- Electrotyping baths contain strong acids or bases, so it is important to wear gloves and eye protection when working with them.

- Electrotyping baths also produce hydrogen gas, which is flammable. It is important to work in a well-ventilated area and to keep the baths away from open flames.

6. What are the different types of electrotyping machines?

- There are two main types of electrotyping machines: manual and automatic.

- Manual machines are operated by hand, while automatic machines are controlled by a computer.

- Automatic machines are more efficient and precise than manual machines, but they are also more expensive.

7. What are the different types of electroplating metals?

- The most common electroplating metals are copper, nickel, and chromium.

- Copper is used for its high conductivity and corrosion resistance.

- Nickel is used for its hardness and wear resistance.

- Chromium is used for its high corrosion resistance and decorative appearance.

8. What are the different types of electrotyping molds?

- The most common electrotyping molds are made of wax, plastic, or metal.

- Wax molds are easy to make and inexpensive, but they are not as durable as plastic or metal molds.

- Plastic molds are more durable than wax molds, but they are more expensive.

- Metal molds are the most durable, but they are also the most expensive.

9. What are the different types of electrotyping finishes?

- The most common electrotyping finishes are bright, matte, and satin.

- Bright finishes are highly reflective, while matte finishes are non-reflective.

- Satin finishes are somewhere in between bright and matte finishes.

10. What are the different types of electrotyping equipment?

- The most common electrotyping equipment includes:

- Electroplating baths

- Electrotyping machines

- Electroplating metals

- Electrotyping molds

- Electrotyping finishes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrotyper Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrotyper Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Electrotyper Apprentice plays a crucial role in the electrotyping process, assisting experienced electrotypers in the production of metal duplicates of original forms.

1. Assisting in Mold Making

Apprentices help prepare the original form for electrotyping by applying a conductive coating and creating a mold using wax or other materials.

- Preparing the original form by cleaning and applying a conductive coating to ensure proper electrical conductivity.

- Creating a mold using materials such as wax or plastic to capture the details of the original form.

2. Electroplating and Finishing

Apprentices assist in electroplating the mold to create the metal duplicate and perform finishing operations to achieve the desired surface quality.

- Setting up and monitoring electroplating baths to deposit metal onto the mold, ensuring proper thickness and quality.

- Performing finishing operations such as polishing, buffing, and engraving to achieve the required surface finish and dimensional accuracy.

3. Maintenance and Inspection

Apprentices help maintain electrotyping equipment and inspect metal duplicates to ensure quality and accuracy.

- Performing routine maintenance tasks on electroplating equipment, such as cleaning and calibrating baths.

- Inspecting metal duplicates for defects, such as voids, cracks, or dimensional inaccuracies, and reporting any issues to the supervisor.

4. Safety and Environmental Compliance

Apprentices must adhere to safety regulations and maintain a clean and environmentally compliant work area.

- Following established safety protocols, including the proper handling and disposal of chemicals.

- Maintaining a clean and organized work area to minimize hazards and ensure efficient operations.

Interview Tips

Preparing thoroughly for an Electrotyper Apprentice interview can significantly increase your chances of success. Here are some valuable tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company’s history, products, and electrotyping industry trends. This will help you understand the company’s culture and the role of an Electrotyper Apprentice within the industry.

- Visit the company’s website to gather information about their business, mission, and products or services.

- Read industry publications and articles to stay updated on the latest advancements and challenges in electrotyping.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare your responses to highlight your relevant skills and experience. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Tell me about your experience in mold making.

- Describe a time when you had to troubleshoot an electroplating issue.

- How do you ensure the quality and accuracy of metal duplicates?

3. Emphasize Your Technical Skills and Knowledge

Highlight your technical skills in electrotyping, including electroplating, mold making, and metal finishing. If you have any certifications or training in these areas, be sure to mention them.

- Describe your understanding of the electrotyping process and the different techniques involved.

- Discuss your experience with electroplating equipment and materials.

- Explain your knowledge of safety regulations and environmental compliance in electrotyping.

4. Show Your Passion and Commitment

Convey your enthusiasm for electrotyping and your desire to learn and grow in the field. Express your commitment to delivering high-quality work and contributing to the company’s success.

- Explain why you are interested in electrotyping and what drew you to this apprenticeship program.

- Describe your career aspirations and how this apprenticeship aligns with your future goals.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Electrotyper Apprentice, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Electrotyper Apprentice positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.