Are you gearing up for an interview for a Job Lithographer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Job Lithographer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

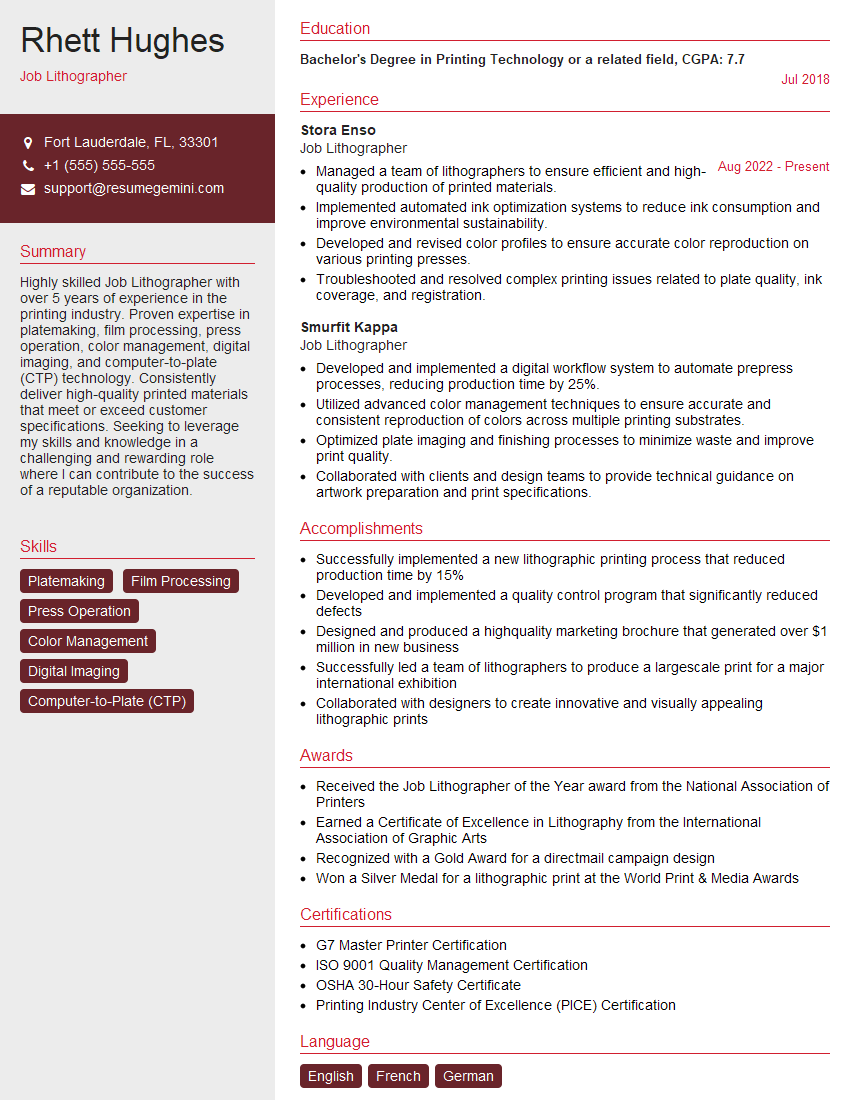

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Job Lithographer

1. How do you ensure color accuracy during the lithographic printing process?

To ensure color accuracy during the lithographic printing process, I follow these steps:

- Proofing and Pre-Press: I conduct thorough pre-press proofing to verify color reproduction and make any necessary adjustments to the digital files.

- Color Calibration: I calibrate the printing press and equipment regularly using spectrophotometers and densitometers to achieve accurate color matching.

- Use of Standard Ink Colors: I use standard ink colors and mix them according to the specified Pantone or CMYK values to ensure consistency.

- On-Press Color Control: During printing, I monitor the ink density, color balance, and registration closely and make real-time adjustments as needed.

- Post-Press Verification: After printing, I perform post-press checks to ensure that the final printed materials meet the desired color requirements.

2. Describe the different types of lithographic printing plates and their uses.

Positive Plates

- Image areas are receptive to ink and non-image areas are water receptive.

- Used for general commercial printing, brochures, posters, and packaging.

Negative Plates

- Non-image areas are ink receptive and image areas are water receptive.

- Suitable for printing newspapers, magazines, and books.

Bi-Metallic Plates

- Combine the properties of both positive and negative plates.

- Provide excellent ink transfer and image stability, ideal for high-quality offset printing.

CTP (Computer-to-Plate) Plates

- Laser-engraved plates that eliminate the need for film and manual platemaking.

- Offer high precision and reproducibility.

3. Explain the process of dampening in lithography.

Dampening in lithography involves applying a water-based solution to the non-image areas of the printing plate.

- Purpose: To keep the non-image areas water receptive and prevent them from attracting ink.

- Methods: Using a dampening system on the printing press or manually applying water with a dampening roller.

- Variables: Dampening solution composition (pH, conductivity), water temperature, and dampening roller settings.

- Importance: Proper dampening ensures sharp image reproduction and prevents ink smearing.

4. Describe the role of ink in lithographic printing.

Ink in lithographic printing plays a crucial role in transferring the image from the plate to the substrate.

- Properties: Lithographic inks are oil-based and have specific rheological characteristics for optimal transfer.

- Types: Ink formulations vary depending on the substrate, printing speed, and desired results.

- Application: Ink is applied to the image areas of the printing plate and transferred to the substrate during the printing process.

- Ink-Water Balance: Controlling the balance between ink and water on the plate is essential for achieving the desired image quality.

5. How do you troubleshoot common lithographic printing problems, such as ghosting and slurring?

To troubleshoot common lithographic printing problems:

- Ghosting: Caused by excessive moisture on the non-image areas. I adjust the dampening system, check for plate contamination, and ensure proper ink-water balance.

- Slurring: Occurs when the image appears elongated or distorted. I inspect the plate for damage, adjust the impression pressure, and check the press settings.

- Mottling: Caused by uneven ink distribution. I troubleshoot by checking the ink viscosity, cleaning the rollers, and adjusting the fountain settings.

- Tinting: Occurs when color is transferred to non-image areas. I examine the plate for scratches or contamination, check the dampening system, and adjust the ink-water balance.

6. What are the advantages of using a web press in lithographic printing?

Advantages of using a web press in lithographic printing:

- High Speed: Web presses operate at faster speeds than sheet-fed presses, increasing productivity.

- Continuous Printing: The paper is fed into the press in a continuous roll, allowing for uninterrupted printing.

- Web Tension Control: Web presses maintain precise tension on the paper, reducing wrinkles and ensuring consistent print quality.

- Efficient Ink Usage: Web presses use ink fountains that circulate and distribute ink evenly, minimizing waste.

- Automated Processes: Web presses often feature automated systems for paper feeding, plate changing, and ink control.

7. Explain the process of calibration in lithographic printing.

Calibration in lithographic printing involves adjusting and verifying the equipment and materials to ensure accurate and consistent printing.

- Press Calibration: Involves adjusting the impression pressure, ink density, and register settings to meet the desired print specifications.

- Plate Calibration: Ensuring that the printing plates are properly exposed and developed to achieve optimal ink transfer.

- Ink Calibration: Calibrating the ink viscosity and pH to match the press and substrate requirements.

- Densitometry: Using densitometers to measure the ink density and color values on the printed sheets and compare them to the target values.

- Regular Monitoring: Calibration procedures should be performed regularly to maintain consistent print quality.

8. What is a lithographic blanket and what are its functions?

A lithographic blanket is a flexible material that wraps around the impression cylinder of a lithographic printing press.

- Functions:

- Transfers the inked image from the printing plate to the substrate.

- Provides a smooth, even surface for printing, reducing dot gain and improving image quality.

- Absorbs ink and releases it during the printing process, ensuring proper ink transfer.

9. Describe the different types of coatings used in lithographic printing and their purposes.

- Varnish: Provides a protective layer over the printed ink, enhancing durability and resistance to scratches and moisture.

- UV Coating: Cured using ultraviolet light, UV coatings offer high gloss, durability, and scratch resistance.

- Lamination: A thin plastic film applied to the printed surface, providing protection against moisture, wear, and fading.

- Foiling: A metallic or colored film applied to the printed surface to create a decorative or eye-catching effect.

- Embossing: A process that raises the surface of the paper to create a three-dimensional effect.

10. What are the environmental considerations when operating a lithographic printing press?

- Ink and Solvent Usage: Using environmentally friendly inks and solvents, as well as minimizing their consumption.

- Waste Management: Properly disposing of waste materials, including ink, solvents, and paper scrap, to minimize environmental impact.

- Energy Efficiency: Optimizing energy consumption by using energy-efficient equipment and practices.

- Paper Selection: Choosing sustainable paper sources and using recycled or biodegradable papers.

- Compliance with Regulations: Adhering to environmental regulations and industry standards to minimize the environmental footprint.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Job Lithographer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Job Lithographer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Job Lithographers create and pre-press negatives used in the printing process. They work with printing and binding operators to translate customer requirements into physical printing materials.

1. Operating Printing Machines

Job Lithographers operate printing machines to create quality prints. They ensure accurate and consistent print runs by calibrating and maintaining machines.

- Setting up and operating various printing presses

- Mixing and matching colors to create desired shades

- Inspecting prints for quality and accuracy

2. Creating Pre-Press Negatives

Job Lithographers create pre-press negatives using specialized software and equipment. They utilize techniques such as photolithography and platemaking to transfer designs onto printing plates.

- Developing and correcting digital files for printing

- Creating photolithographic plates for offset printing

- Ensuring negatives meet color and resolution specifications

3. Troubleshooting and Problem Solving

Job Lithographers troubleshoot and resolve issues that arise during the printing process. They analyze print quality, identify defects, and implement necessary adjustments to optimize results.

- Diagnosing and fixing printing errors, such as color variations and misregistration

- Inspecting and adjusting printing presses to maintain optimal performance

- Collaborating with other departments to identify and resolve issues

4. Maintaining and Cleaning Equipment

Job Lithographers maintain and clean printing equipment to ensure its proper functioning. They perform regular inspections, lubricate machinery parts, and replace worn components.

- Cleaning and maintaining printing presses, guillotines, and other equipment

- Replacing worn or damaged parts to prevent breakdowns

- Adhering to safety protocols and maintaining a clean and organized workspace

Interview Preparation Tips

Job Lithographers play a crucial role in the printing industry. Preparing for an interview can help you demonstrate your skills and increase your chances of success.

1. Research the Company and Industry

Research the company and the printing industry to gain insights into their products, services, and market trends. This will help you understand the company’s needs and tailor your answers accordingly.

- Visit the company website and social media pages

- Read industry publications and news articles

- Connect with current or former employees if possible

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare your answers in advance. This will boost your confidence and ensure you deliver well-organized and informative responses.

- Example Outline:

- Tell me about yourself and your experience.

- Why are you interested in this position?

- Why should we hire you over other candidates?

- What is your understanding of the role?

- How do you handle pressure and deadlines?

3. Highlight Your Skills and Experience

Showcase your relevant skills and experience that align with the job responsibilities. Provide specific examples to demonstrate your capabilities and achievements.

- Quantify your accomplishments using numbers and metrics

- Use the STAR method to articulate situations, tasks, actions, and results

- Share examples that demonstrate problem-solving abilities, attention to detail, and teamwork skills

4. Be Enthusiastic and Professional

Project a positive and enthusiastic attitude during the interview. Dress professionally, maintain eye contact, and speak clearly and confidently.

- Show your interest in the position and the company

- Be respectful and courteous towards the interviewer

- Ask thoughtful questions to demonstrate your engagement

Next Step:

Now that you’re armed with the knowledge of Job Lithographer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Job Lithographer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini