Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Layup Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Layup Worker so you can tailor your answers to impress potential employers.

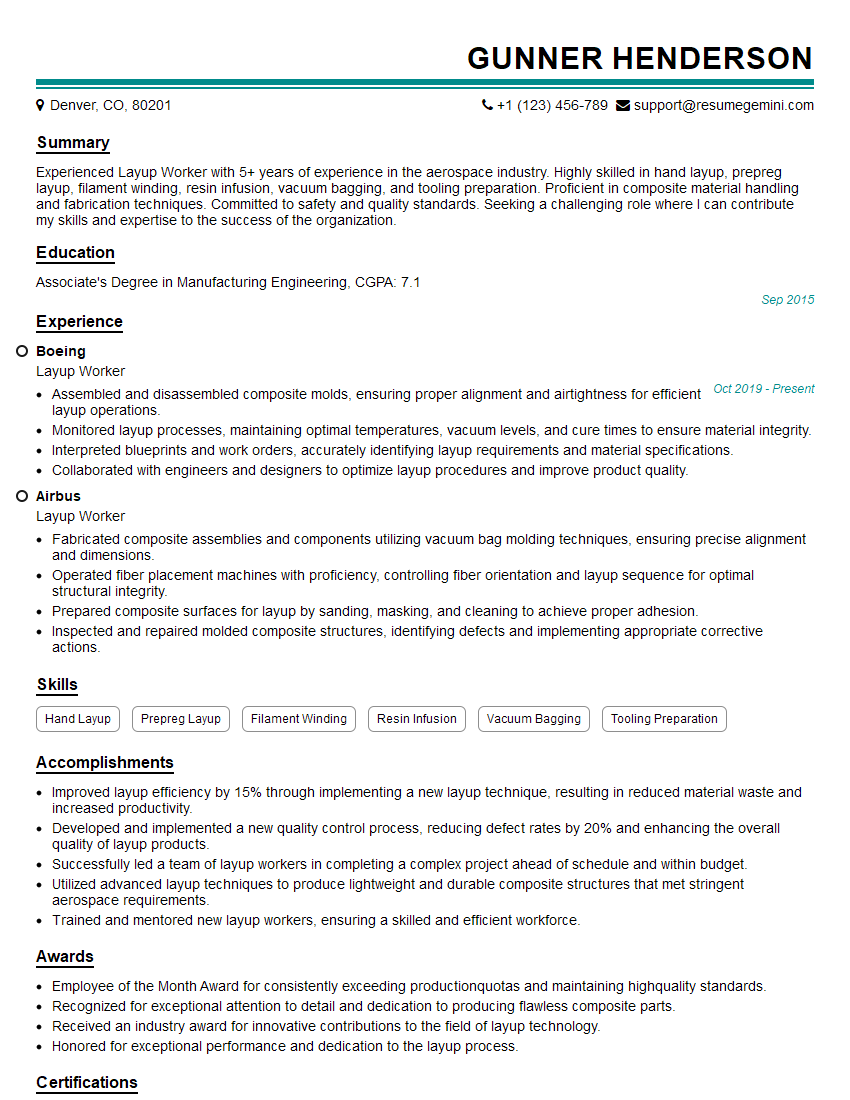

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Layup Worker

1. Describe the process of preparing a layup mold?

The process of preparing a layup mold involves the following steps:

- Cleaning and preparing the mold surface to ensure a smooth and clean surface for layup.

- Applying a release agent to prevent the composite material from bonding to the mold.

- Positioning and securing the layup materials, such as fiberglass or carbon fiber, onto the mold.

- Applying resin or adhesive to the layup materials and ensuring proper impregnation.

- Compact the layup using vacuum bagging or other techniques to remove air and consolidate the materials.

- Curing the layup at a specific temperature and pressure to achieve the desired properties.

2. Explain the different types of layup techniques?

Hand Layup

- Applying resin and reinforcing materials manually using brushes or rollers.

- Suitable for small or complex shapes with low production volumes.

Vacuum Bagging

- Placing the layup inside a vacuum bag and applying vacuum to remove air and compact the materials.

- Provides better consolidation and higher fiber content, resulting in improved mechanical properties.

Prepreg Layup

- Using pre-impregnated reinforcing materials that have been coated with resin.

- Offers high accuracy and consistency, suitable for high-performance applications.

Automated Layup

- Utilizing machines to automate the layup process, such as fiber placement or robotic spraying.

- Provides increased efficiency, accuracy, and consistency for large production volumes.

3. What factors affect the quality of a layup?

- Proper preparation of the mold surface

- Accurate cutting and placement of the reinforcing materials

- Correct mixing and application of the resin

- Effective removal of air during compaction

- Appropriate curing conditions and temperature control

- Post-curing processes, such as trimming and finishing

4. Describe the different types of defects that can occur in a layup?

- Voids: Air pockets trapped within the layup, reducing strength and durability.

- Delamination: Separation between layers of the layup, compromising structural integrity.

- Cracking: Fractures or breaks in the layup due to stress or improper curing.

- Wrinkles: Uneven surface on the layup caused by improper compaction or tensioning.

- Fiber Orientation: Misalignment of fibers, affecting the mechanical properties of the layup.

5. What are the safety precautions to be observed when working with layup materials?

- Wear appropriate personal protective equipment (PPE), including gloves, respirators, and protective clothing.

- Handle chemicals and resins with care, following proper storage and disposal procedures.

- Ensure proper ventilation in the work area to prevent exposure to fumes and dust.

- Be aware of the potential for slipping or tripping hazards in the work environment.

- Receive training and follow established safety protocols for the specific materials and processes used.

6. How do you measure and control the thickness of a layup?

- Use thickness gauges, such as micrometers or ultrasonic thickness gauges, to measure the thickness at various points.

- Control the thickness by adjusting the amount of reinforcing materials used and the compaction pressure.

- Monitor the resin flow and ensure proper impregnation to achieve the desired thickness.

- Follow pre-determined layup schedules or specifications that outline the target thicknesses for each layer.

7. What is the importance of surface preparation before layup?

- Ensures a clean and smooth surface for proper adhesion of the layup materials.

- Removes contaminants, such as dirt, oil, or moisture, that can weaken the bond.

- Improves the surface texture, providing a better mechanical interlock between the layup and the mold.

- Prevents air entrapment and improves the overall quality of the layup.

8. Describe the process of post-curing a layup?

- Raising the temperature of the cured layup to a specific level, typically using ovens or heat blankets.

- Holding the temperature for a defined period to complete the curing process and enhance the material properties.

- Cooling the layup slowly and controlled to minimize thermal stresses and prevent cracking.

- Post-curing improves mechanical strength, dimensional stability, and resistance to environmental factors.

9. What are the different techniques used to inspect layups for defects?

- Visual Inspection: Examining the layup surface for visible defects, such as cracks, wrinkles, or voids.

- Ultrasonic Testing: Using high-frequency sound waves to detect internal defects, such as delamination or porosity.

- Radiography: Using X-rays or gamma rays to create images of the layup, revealing internal defects and material distribution.

- Non-Destructive Testing (NDT): Employing various methods, such as acoustic emission testing or vibration analysis, to identify defects without damaging the layup.

10. Explain the importance of following layup procedures accurately?

- Ensures consistent quality and performance of the layup.

- Reduces the risk of defects and failures by adhering to established best practices.

- Optimizes the use of materials and minimizes waste.

- Facilitates troubleshooting and problem-solving during the layup process.

- Complies with industry standards and regulations, ensuring safety and reliability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Layup Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Layup Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Layup Workers are responsible for assembling and reinforcing aircraft parts, such as wings and fuselages. They work in a fast-paced environment and must have a strong attention to detail. Key job responsibilities include:

1. Laying up and assembling aircraft parts

Layup Workers use various materials, such as fiberglass, carbon fiber, and aluminum, to create aircraft parts. They must follow precise instructions and ensure that the parts are assembled correctly.

2. Reinforcing aircraft parts

Layup Workers use a variety of techniques to reinforce aircraft parts, such as adding stiffeners, doublers, and other structural elements. They must ensure that the parts are strong enough to withstand the stresses of flight.

3. Inspecting aircraft parts

Layup Workers inspect aircraft parts to ensure that they meet quality standards. They look for defects, such as cracks, voids, and delaminations. They also check the parts for proper fit and finish.

4. Maintaining a clean and safe work area

Layup Workers are responsible for maintaining a clean and safe work area. They must keep their tools and equipment organized and clean up any spills or debris. They must also follow all safety procedures.

Interview Tips

There are some tips and hacks you can do to prepare for an Layup Worker interview:

1. Research the company

Take some time to learn about the company you’re interviewing with. This will show the interviewer that you’re interested in the position and that you’ve taken the time to learn about their company.

2. Practice your answers to common interview questions

There are a few common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Layup Worker. Be prepared to talk about your skills and knowledge, and how you’ve used them in previous roles.

4. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing excessive jewelry or perfume.

5. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you’re running late, be sure to call the interviewer and let them know.

6. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

Next Step:

Now that you’re armed with the knowledge of Layup Worker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Layup Worker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini