Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lithographic Platemaker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lithographic Platemaker so you can tailor your answers to impress potential employers.

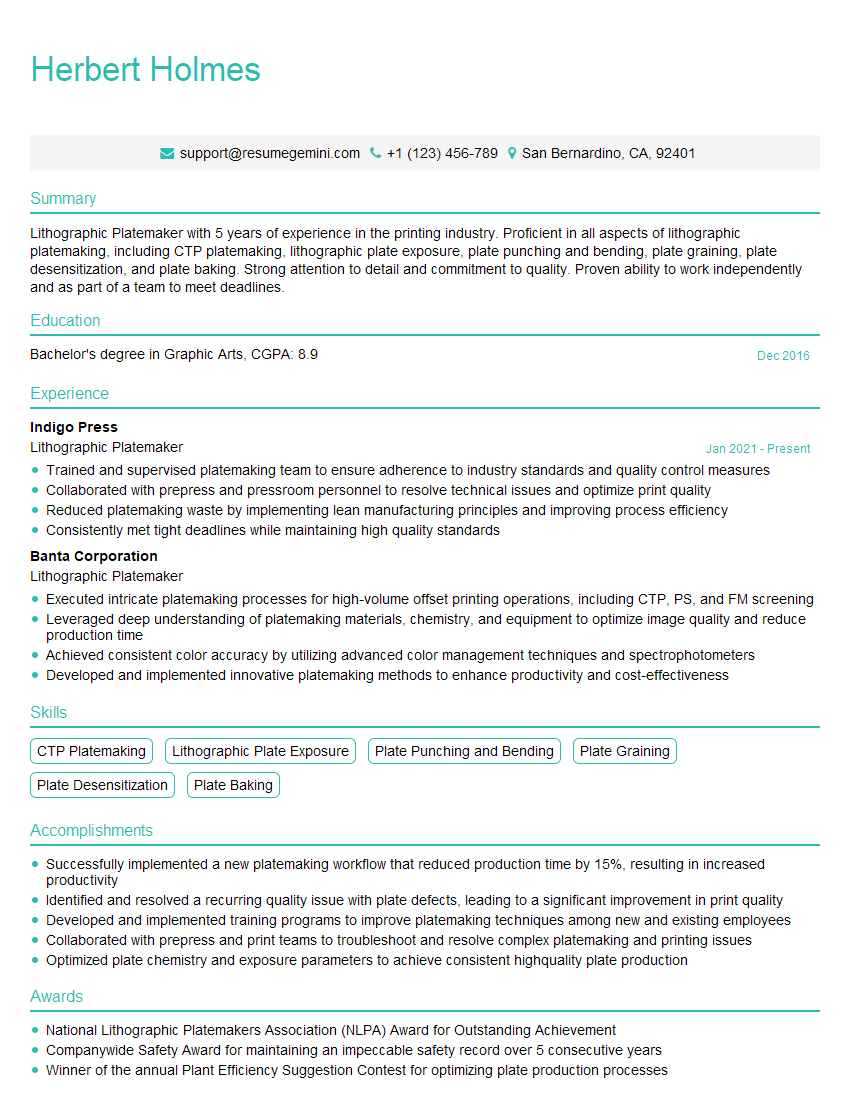

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lithographic Platemaker

1. What is the purpose of a lithographic platemaker?

A lithographic platemaker is responsible for creating printing plates used in lithographic printing. This involves converting digital or analog artwork into a physical plate that can be used to transfer ink to paper.

2. What are the different types of lithographic plates?

- Positive plates

- Negative plates

- Presensitized plates

- Non-presensitized plates

3. What is the difference between a positive and negative plate?

A positive plate has the image areas protected by a light-sensitive coating, while the non-image areas are exposed. A negative plate has the non-image areas protected by a light-sensitive coating, while the image areas are exposed.

4. What is the process of creating a lithographic plate?

- Preparing the artwork

- Creating a film positive or negative

- Exposing the plate to light

- Developing the plate

- Baking the plate

5. What are the quality control checks that need to be performed on a lithographic plate?

- Checking the plate for defects

- Measuring the plate thickness

- Measuring the plate density

- Checking the plate for pinholes

6. What are the different types of lithographic printing presses?

- Sheetfed presses

- Web presses

- Offset presses

- Gravure presses

7. What are the different types of paper that can be used in lithographic printing?

- Coated paper

- Uncoated paper

- Newsprint

- Specialty papers

8. What are the different types of ink that can be used in lithographic printing?

- Oil-based inks

- Water-based inks

- UV inks

- Specialty inks

9. What are the common problems that can occur in lithographic printing?

- Ink smudging

- Paper wrinkles

- Plate defects

- Press problems

10. What are the safety precautions that need to be taken when working with lithographic printing materials?

- Wearing gloves

- Wearing a mask

- Using proper ventilation

- Storing chemicals properly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lithographic Platemaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lithographic Platemaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lithographic Platemakers are key personnel in the printing industry responsible for preparing printing plates used in offset printing presses. Their primary function involves creating printing plates that transfer images or text onto paper or other materials during the printing process. To excel in this role, it’s essential to possess a strong understanding of lithographic printing techniques and have a keen eye for detail and accuracy.

1. Prepress Preparation

Lithographic Platemakers begin by reviewing print specifications and artwork provided by clients or designers. They analyze the files, identify potential issues, and may make adjustments to optimize the image for printing. This often involves color correction, image manipulation, and ensuring that the file meets the required specifications.

- Examine print specifications and artwork thoroughly.

- Make necessary adjustments to images for optimal printing.

- Ensure files adhere to predetermined specifications.

2. Plate Creation

Once the artwork is prepared, Platemakers create printing plates using specialized equipment called a platemaker or CTP (Computer-to-Plate) device. They select the appropriate plate material and follow a precise process to transfer the digital image onto the plate. This involves exposing the plate to light or laser beams, developing the image using chemicals, and post-processing to ensure the plate is ready for printing.

- Select the suitable plate material based on printing requirements.

- Utilize platemakers or CTP devices to transfer the digital image onto the plate.

- Develop and process the plate using chemicals and specialized techniques.

- Ensure the plate meets the desired specifications and is print-ready.

3. Quality Control

Lithographic Platemakers play a crucial role in maintaining quality standards throughout the printing process. They meticulously inspect the plates for defects, such as scratches, pinholes, or incorrect exposure. They also verify that the plate matches the original artwork and meets the specified printing requirements. If any issues are identified, they may need to correct or remake the plate to ensure the best possible print quality.

- Thoroughly inspect plates for any defects or errors.

- Ensure the plate accurately reflects the original artwork.

- Verify that the plate meets the specified printing specifications.

- Take corrective actions to address any identified issues.

4. Troubleshooting and Maintenance

Lithographic Platemakers are often responsible for troubleshooting and resolving issues that may arise during the platemaking process. They possess a deep understanding of the equipment and materials used and can quickly identify and address any problems that may occur. They also perform regular maintenance on equipment to ensure optimal performance and prevent breakdowns.

- Identify and resolve issues that may arise during the platemaking process.

- Possess a thorough understanding of platemaking equipment and materials.

- Perform routine maintenance on equipment to ensure smooth operations.

- Collaborate with other team members to minimize downtime and maintain production efficiency.

Interview Tips

Preparing for a Lithographic Platemaker interview requires thorough research and practice. Here are some valuable tips to help you ace the interview and showcase your skills and qualifications:

1. Research the Company and Position

Before the interview, take the time to thoroughly research the printing company and the specific role of a Lithographic Platemaker within their organization. Understand their printing capabilities, clientele, and industry reputation. This knowledge will demonstrate your interest and enthusiasm for the position.

- Visit the company website and social media pages.

- Read industry publications to gain insights into the company.

- Connect with current or former employees on LinkedIn.

2. Highlight Your Technical Skills

During the interview, be prepared to discuss your technical skills and experience in lithographic platemaking. Emphasize your expertise in prepress preparation, plate creation, quality control, and troubleshooting. Provide specific examples of how you have applied these skills in previous roles to deliver high-quality print results.

- Describe your experience with different plate materials and printing techniques.

- Showcase your proficiency in using platemaking equipment and software.

- Provide examples of how you have identified and resolved platemaking issues.

3. Demonstrate Your Attention to Detail

Lithographic Platemakers must have a keen eye for detail and a commitment to accuracy. In the interview, highlight your ability to meticulously inspect plates for defects and ensure they meet the required specifications. Share examples of how you have maintained high-quality standards throughout the platemaking process.

- Emphasize your ability to identify even the smallest errors.

- Explain how you use quality control tools and techniques to ensure accuracy.

- Describe your experience in meeting tight deadlines without compromising quality.

4. Prepare for Common Interview Questions

Familiarize yourself with common interview questions that Lithographic Platemakers may encounter. Practice answering these questions concisely and effectively. Some common questions include:

- Tell me about your experience in lithographic platemaking.

- How do you ensure the accuracy and quality of the printing plates you create?

- What are some challenges you have faced in your previous role as a Lithographic Platemaker?

- How do you stay up-to-date with the latest advancements in lithographic printing technology?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lithographic Platemaker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lithographic Platemaker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.