Are you gearing up for an interview for a Photoengraver position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Photoengraver and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

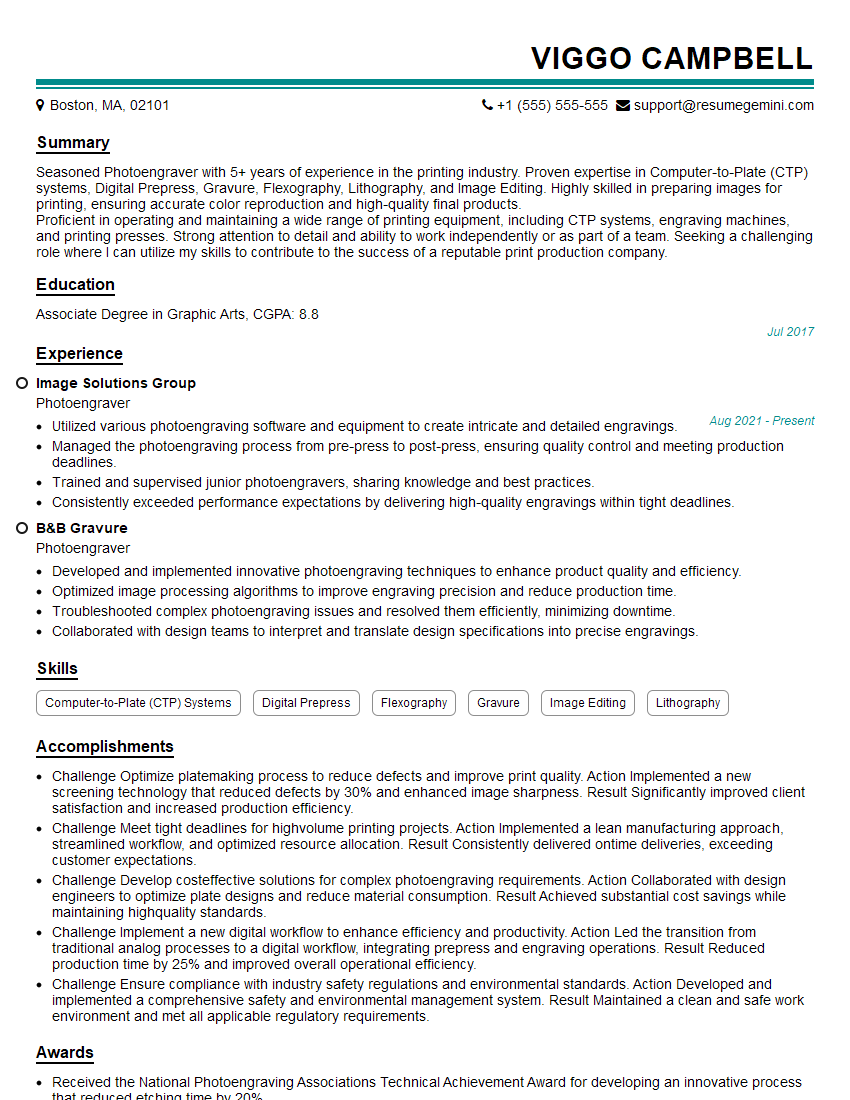

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Photoengraver

1. What is the process of photoengraving?

Photoengraving is a process of creating a metal printing plate from a photographic negative. The negative is placed on a metal plate, and exposed to light. The exposed areas of the plate are then etched away, leaving a raised image on the plate. This image can then be used to print images onto paper or other materials.

2. What are the different types of photoengraving?

Intaglio printing

- The image is recessed into the printing plate.

- The plate is inked, and the excess ink is wiped away.

- Paper is pressed into the plate, picking up the ink from the recessed areas.

Relief printing

- The image is raised on the printing plate.

- The plate is inked, and the ink is transferred to paper when the plate is pressed against it.

Planographic printing

- The image is created on a flat surface.

- The plate is moistened, and the ink is attracted to the unmoistened areas.

- Paper is pressed against the plate, picking up the ink from the unmoistened areas.

3. What are the different types of printing presses used in photoengraving?

- Platen presses

- Cylinder presses

- Rotary presses

4. What are the different materials used in photoengraving?

- Metal plates

- Photographic negatives

- Etching solutions

- Inks

- Paper

5. What are the safety precautions that must be taken when working with photoengraving chemicals?

- Wear gloves and protective clothing.

- Work in a well-ventilated area.

- Avoid contact with skin and eyes.

- Dispose of chemicals properly.

6. What are the different types of defects that can occur in photoengraving?

- Scratches

- Dents

- Etching errors

- Ink problems

- Paper problems

7. How do you troubleshoot printing problems?

There are many different types of printing problems that can occur, so it is important to troubleshoot the problem to determine the cause. Some common troubleshooting steps include:

- Inspecting the printing plate

- Checking the ink and paper

- Adjusting the printing press

- Cleaning the printing press

8. What are the different types of finishing processes that can be used on photoengraved prints?

- Trimming

- Binding

- Laminating

- Embossing

- Foil stamping

9. What are the different types of careers that are available in the photoengraving industry?

- Photoengravers

- Printers

- Binders

- Sales representatives

- Managers

10. What are the different skills and qualifications that are required for a photoengraver?

- Knowledge of photoengraving techniques

- Experience with printing presses

- Ability to troubleshoot printing problems

- Attention to detail

- Manual dexterity

- Excellent eyesight

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Photoengraver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Photoengraver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Photoengravers are responsible for creating metal printing plates that are used in the printing industry. They use a variety of techniques to transfer images onto metal, including photoengraving, etching, and electroplating.

1. Prepare metal plates for engraving

Before engraving can begin, the metal plate must be prepared. This involves cleaning the plate to remove any dirt or debris, and then applying a light-sensitive coating to the surface of the plate.

- Clean metal plates using solvents and brushes.

- Apply a light-sensitive coating to the surface of the plate.

2. Expose the plate to light

The next step is to expose the plate to light. This is done by placing a negative or transparency on the plate and then exposing it to a light source. The light will cause the light-sensitive coating to harden in the areas that are exposed to light.

- Place a negative or transparency on the plate.

- Expose the plate to a light source.

3. Develop the plate

Once the plate has been exposed to light, it is developed. This involves immersing the plate in a chemical solution that will remove the unexposed areas of the light-sensitive coating. The result is a metal plate with a raised image.

- Immerse the plate in a chemical solution.

- Remove the unexposed areas of the light-sensitive coating.

4. Etch the plate

The next step is to etch the plate. This involves immersing the plate in an acid solution that will eat away at the metal in the unexposed areas. The result is a metal plate with a recessed image.

- Immerse the plate in an acid solution.

- Etch away the metal in the unexposed areas.

5. Electroplate the plate

The final step is to electroplate the plate. This involves immersing the plate in a metal solution and then passing an electric current through the solution. The result is a metal plate with a thin layer of metal deposited on the surface.

- Immerse the plate in a metal solution.

- Pass an electric current through the solution.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a photoengraver position:

1. Research the company

Before you go to your interview, take some time to research the company. This will help you understand their business, their culture, and their values. It will also help you answer questions about the company in a way that shows you’re interested and informed.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work for the company.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions.

- Tell a story that highlights your skills and experience.

- Be specific and provide examples.

3. Be prepared to talk about your portfolio

As a photoengraver, your portfolio is one of the most important things you can bring to an interview. It’s a showcase of your work and your skills. Make sure your portfolio is up-to-date and that it includes your best work.

- Bring a physical portfolio to your interview.

- Create an online portfolio that you can share with interviewers.

- Be prepared to talk about your work in detail.

4. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or dress pants and a button-down shirt. You should also make sure your shoes are clean and polished.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your shoes are clean and polished.

- Avoid wearing anything too revealing or too casual.

5. Be confident and enthusiastic

Confidence is key in an interview. Make sure you maintain eye contact with the interviewer and speak clearly and confidently. You should also be enthusiastic about the position and the company.

- Maintain eye contact with the interviewer.

- Speak clearly and confidently.

- Be enthusiastic about the position and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Photoengraver, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Photoengraver positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.