Are you gearing up for a career in Photoengraving Finisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Photoengraving Finisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

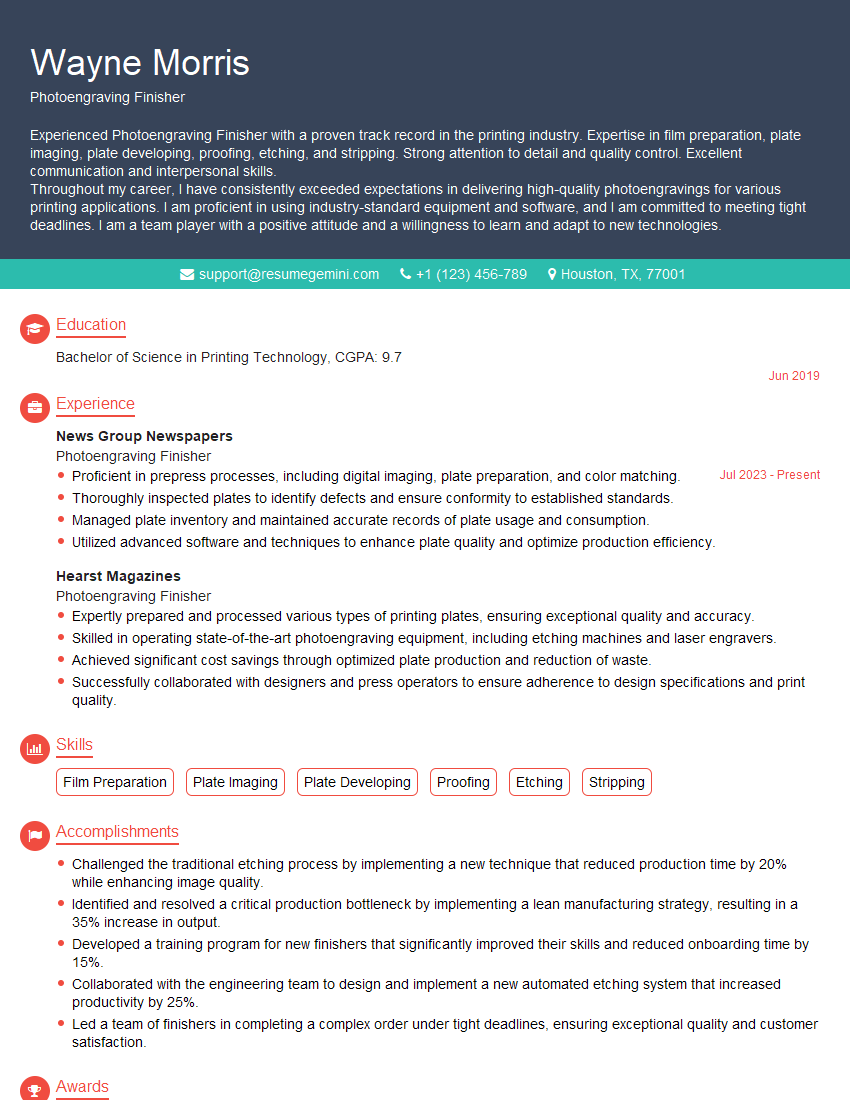

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Photoengraving Finisher

1. Describe the steps involved in the photoengraving finishing process?

The photoengraving finishing process involves several steps to create high-quality print plates. Here’s an overview:

- Proofing: Checking the final proofs to ensure accuracy and quality before proceeding with platemaking.

- Imposition: Arranging and aligning the images and text on the plate to optimize printing efficiency.

- Platemaking: Creating the actual printing plate using specialized equipment and techniques.

- Etching: Submerging the plate in an acid bath to etch away non-image areas, creating raised image areas for printing.

- Finishing: Trimming and fine-tuning the plate to meet specifications, ensuring optimal performance on the press.

2. Explain the different types of photoengraving plates and their applications?

Metal Plates

- Copper: Durable, high-quality plates for long print runs and detailed images.

- Zinc: Less expensive than copper, suitable for shorter runs and less demanding applications.

Polymer Plates

- Flexographic: Flexible, photopolymer plates used in packaging and label printing.

- Letterpress: Rigid, photopolymer plates for letterpress printing, providing excellent impression depth.

Digital Plates

- Computer-to-plate (CTP): Plates created directly from digital files, eliminating the need for film.

- Direct laser engraving (DLE): Plates engraved using a laser, providing high resolution and accuracy.

3. What are the key factors that affect the quality of photoengraved plates?

- Image resolution: The higher the resolution, the finer the detail and sharper the images.

- Etching depth: The depth of the etched areas determines the ink transfer and print quality.

- Plate cleanliness: Any contamination on the plate can interfere with the printing process.

- Equipment maintenance: Regular maintenance of engraving and etching equipment ensures optimal performance.

- Operator skill: The experience and expertise of the photoengraver plays a crucial role in plate quality.

4. Describe the role of color separation in photoengraving?

Color separation is the process of breaking down an image into its individual color components (CMYK). Each color component is then engraved onto a separate plate. When combined during printing, these plates reproduce the original image.

- Cyan, Magenta, Yellow, and Key (Black): These four colors are used to create a full-color image.

- Spot colors: Additional colors used for specific elements, such as metallic or fluorescent inks.

5. What are the safety precautions that must be followed when working with photoengraving chemicals?

- Wear protective gear: Gloves, apron, eye protection, and a respirator when necessary.

- Proper ventilation: Ensure adequate ventilation in work areas to prevent chemical exposure.

- Safe handling of chemicals: Follow manufacturer’s instructions for handling and disposal of chemicals.

- Emergency preparedness: Know the location of safety showers and eyewash stations.

- Regular training: Receive proper training on chemical handling and safety protocols.

6. What techniques do you use to inspect and evaluate the quality of photoengraved plates?

- Visual inspection: Examining the plate for defects, such as scratches, pinholes, or uneven etching.

- Microscope inspection: Using a microscope to check for fine details and etching quality.

- Densitometry: Measuring the optical density of the plate to ensure proper ink transfer.

- Plate testing: Running a print test on a proof press to assess the plate’s performance on the press.

7. Describe the challenges you have faced as a photoengraving finisher and how you overcame them?

Challenge 1:

- Problem encountered

- Steps taken to troubleshoot

- Solution implemented

Challenge 2:

- Problem encountered

- Steps taken to troubleshoot

- Solution implemented

8. What trends or advancements are you aware of in the photoengraving industry?

- Computer-to-plate technology: Eliminating the need for film, reducing turnaround time and improving efficiency.

- Digital imaging: Enhancing image quality and accuracy through digital capture and processing.

- Laser engraving: Providing higher precision and resolution in platemaking.

- Environmental sustainability: Focus on using eco-friendly materials and processes.

9. How do you stay updated with the latest technologies and best practices in photoengraving?

- Industry publications: Reading trade magazines and journals.

- Conferences and workshops: Attending industry events to learn about new developments.

- Online resources: Utilizing websites and online forums for information exchange.

- Training and certification: Pursuing additional training to enhance skills and knowledge.

10. Why are you interested in working as a photoengraving finisher for our company?

Research the company and tailor your answer to highlight your interest in their specific products, services, or reputation in the industry.

- State your relevant skills and experience that align with the company’s needs.

- Express your enthusiasm for the opportunity to contribute to the company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Photoengraving Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Photoengraving Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Photoengraving Finisher is responsible for the final preparation of photoengraved plates for use in printing presses. Their primary duties involve:

1. Plate Preparation

Preparing photoengraved plates for printing by removing excess metal from non-image areas using hand tools, such as scrapers and gravers.

2. Etching

Etching plates to create the desired image depth using chemical solutions.

3. Plating

Electroplating plates to protect them from corrosion and improve their durability.

4. Finishing

Performing final finishing touches, such as polishing and cleaning plates to ensure optimal print quality.

5. Quality Control

Inspecting plates for defects and ensuring they meet printing specifications.

Interview Tips

To ace the interview for a Photoengraving Finisher position, candidates should:

1. Research the Company and Industry

Familiarize themselves with the company’s history, products/services, and industry trends.

2. Highlight Relevant Skills and Experience

Emphasize their proficiency in photoengraving techniques, knowledge of printing processes, and attention to detail.

3. Practice Answering Common Interview Questions

Prepare for questions related to their skills, experience, and understanding of the printing industry. Use the STAR (Situation, Task, Action, Result) method to structure their answers.

4. Showcase Passion and Enthusiasm

Demonstrate their interest in photoengraving and express why they are eager to contribute to the company’s success.

5. Prepare Questions for the Hiring Manager

Ask thoughtful questions about the company, the position, or the industry to show their engagement and interest.

Next Step:

Now that you’re armed with the knowledge of Photoengraving Finisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Photoengraving Finisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini