Are you gearing up for an interview for a Semiconductor Packages Platemaker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Semiconductor Packages Platemaker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

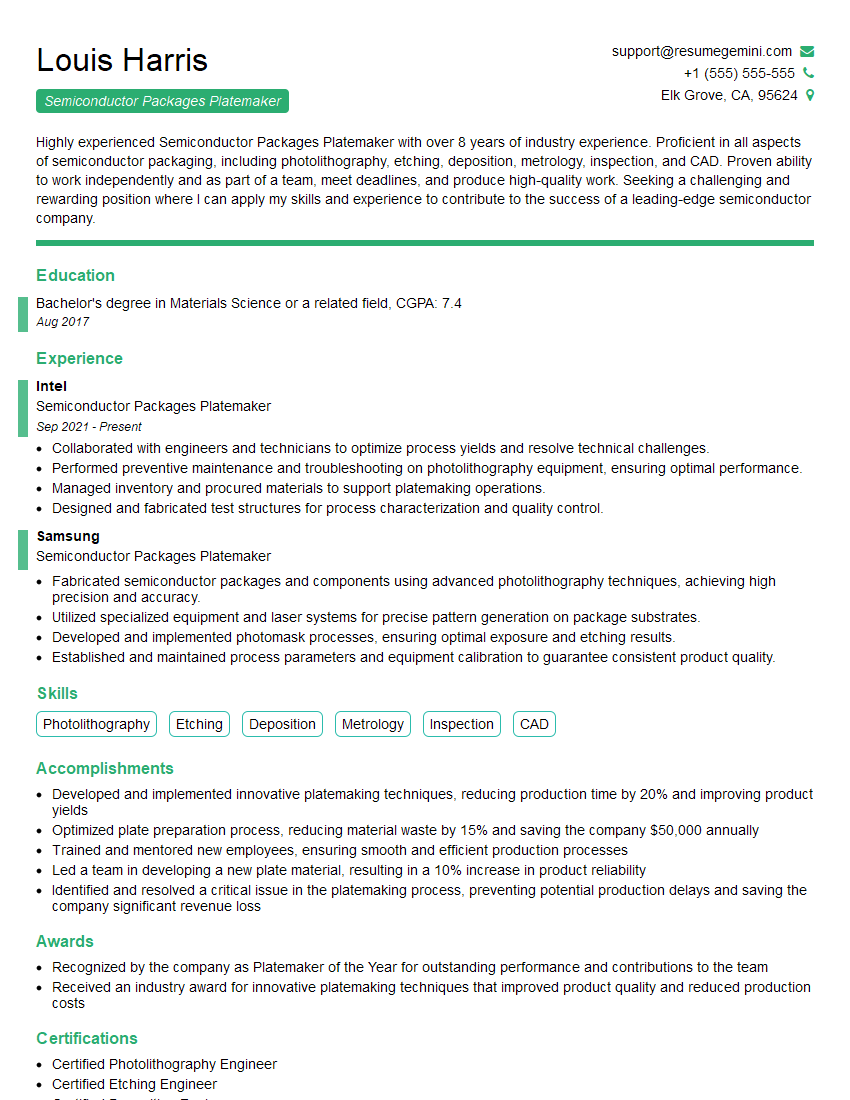

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Packages Platemaker

1. What are the key responsibilities of a Semiconductor Packages Platemaker?

As a Semiconductor Packages Platemaker, my primary responsibilities include:

- Creating photomasks and plates used in the manufacturing of semiconductor packages

- Inspecting photomasks and plates to ensure they meet specifications

- Preparing and exposing photosensitive materials to create precise patterns

- Developing and etching patterns on semiconductor wafers

- Adhering to strict quality control standards and maintaining a cleanroom environment

2. What is the difference between a photomask and a plate in the context of semiconductor packaging?

Definition and Function

- Photomask: A transparent film with opaque patterns that allows light to pass through specific areas, creating patterns on underlying materials.

- Plate: A metal or glass substrate with an opaque layer that blocks light except in exposed areas, used to create patterns through etching.

Role in Semiconductor Packaging

- Photomasks are used in photolithography to transfer circuit patterns onto semiconductor wafers.

- Plates are used in electroplating and etching processes to define metallization patterns on packages.

3. Can you explain the process of creating a photomask for semiconductor packaging?

- Design: Designing the mask layout using CAD software.

- Pattern Generation: Generating a pattern on a chrome-coated glass substrate using electron beam lithography or laser writing.

- Development: Developing the exposed areas to create opaque patterns.

- Inspection: Inspecting the mask for defects and accuracy.

- Hardening: Applying a hardcoat to protect the pattern from wear and tear.

4. What are the different types of inspection methods used for photomasks and plates?

- Visual Inspection: Using microscopes to examine patterns for defects.

- Automated Optical Inspection (AOI): Using specialized equipment to detect patterns and dimensional errors.

- Scanning Electron Microscopy (SEM): Using electron microscopy to analyze surface topography and pattern integrity.

- Coordinate Measuring Machine (CMM): Using a CMM to measure dimensions and locate features with high precision.

5. How do you ensure the cleanliness of plates and photomasks in a cleanroom environment?

- Pre-Cleaning: Using solvents and ultrasonic cleaning to remove contaminants.

- Plasma Cleaning: Using plasma to remove organic residues and improve surface adhesion.

- Handling with Gloves: Wearing cleanroom gloves to prevent contamination.

- Storage in Controlled Environment: Storing plates and photomasks in a cleanroom environment with humidity and temperature control.

- Regular Inspection: Regularly inspecting surfaces for any signs of contamination.

6. Can you discuss the impact of defects on photomasks and plates on the yield of semiconductor packages?

- Pattern Defects: Defects in patterns can lead to shorts, opens, or misalignment, resulting in non-functional packages.

- Surface Defects: Surface defects can cause adhesion issues, affecting the quality of metallization and package reliability.

- Dimensional Errors: Dimensional errors can affect package dimensions, leading to assembly issues or performance problems.

- Increased Scrap Rate: Defects can increase the scrap rate, resulting in higher production costs and lower yields.

7. What are the emerging trends in Semiconductor Packages Platemaking technology?

- High-Resolution Patterning: Techniques like EUV lithography and maskless lithography for finer feature sizes.

- Advanced Inspection Methods: AI-powered inspection systems for faster and more accurate defect detection.

- Automation and Digitization: Automated processes and digital workflow management to improve efficiency and reduce human error.

- Sustainability: Environmentally friendly materials and processes to reduce waste and emissions.

8. How do you stay updated with the latest advancements in Semiconductor Packages Platemaking?

- Attending Industry Conferences: Participating in conferences and workshops to learn about new technologies and best practices.

- Reading Technical Journals: Subscribing to industry publications and staying informed about research and development.

- Networking with Experts: Building relationships with peers and industry professionals to exchange knowledge and insights.

- Company Training Programs: Engaging in training programs provided by the company to enhance skills and stay updated with emerging trends.

9. What is your understanding of package-on-package (PoP) technology?

- Definition: A packaging technique where multiple semiconductor packages are stacked vertically, interconnected, and encapsulated.

- Benefits: Reduced footprint, improved performance, and higher integration density.

- Role of Platemakers: Creating plates that define the electrical connections and interconnects between packages.

10. Can you explain the quality control procedures involved in Semiconductor Packages Platemaking?

- Raw Material Inspection: Inspecting incoming materials for defects and specifications.

- In-Process Inspection: Regularly monitoring the platemaking process to identify potential issues.

- Final Inspection: Thoroughly inspecting finished plates and photomasks for accuracy, defects, and compliance with customer requirements.

- Documentation and Traceability: Maintaining detailed records and ensuring traceability throughout the process.

- Continuous Improvement: Implementing quality improvement initiatives to enhance processes and minimize defects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Packages Platemaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Packages Platemaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Semiconductor Packages Platemaker is accountable for creating and maintaining photolithographic masks used in the manufacturing of semiconductor packages. They work in a cleanroom environment and utilize specialized equipment to produce precise and accurate masks.

1. Mask Design and Fabrication

Understanding and interpreting blueprints and specifications related to mask designs.

- Using computer-aided design (CAD) software to create digital mask layouts.

- Selecting and preparing appropriate photoresists and substrates.

2. Mask Processing

Operating and maintaining photolithographic equipment, including mask aligners and exposure systems.

- Performing photolithographic processes to transfer patterns onto masks.

- Developing and etching masks using chemical processes.

3. Mask Inspection and Analysis

Inspecting masks using microscopes and other optical instruments.

- Identifying and correcting defects or errors in mask patterns.

- Verifying mask dimensions and critical features.

4. Quality Assurance and Control

Participating in quality control procedures.

- Maintaining records and documentation related to mask production.

- Adhering to safety and environmental regulations in the cleanroom.

Interview Tips

Preparing thoroughly for a Semiconductor Packages Platemaker interview can significantly improve your chances of success. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

Before the interview, research the company’s background, products, and current projects. This demonstrates your interest and enthusiasm.

- Look for news articles or industry reports about the company’s recent developments.

- Visit the company’s website to learn about their mission, values, and key products.

2. Practice Your Answers to Common Interview Questions

Anticipate and prepare answers to common interview questions. This will boost your confidence and help you deliver clear and concise responses during the interview.

- Review questions related to your technical skills, such as photolithography, mask design, and inspection.

- Be ready to discuss your experience with cleanroom environments and safety protocols.

3. Showcase Your Technical Proficiency

Highlight your technical proficiency in mask design and photolithographic processes. Quantify your accomplishments and provide specific examples.

- Discuss projects where you successfully fabricated masks with high precision and accuracy.

- Explain your understanding of mask inspection techniques and how you ensure quality control.

4. Emphasize Your Attention to Detail

Emphasize your meticulous attention to detail and your ability to work in a cleanroom environment. This is crucial for the role of a Semiconductor Packages Platemaker.

- Share examples of your ability to detect and correct errors in mask patterns.

- Describe your experience maintaining a clean and organized workspace.

5. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer. This shows your engagement and interest in the position and the company.

- Inquire about the company’s current projects and future goals.

- Ask about the training and support provided to new employees.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Semiconductor Packages Platemaker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Semiconductor Packages Platemaker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.