Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Striping Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

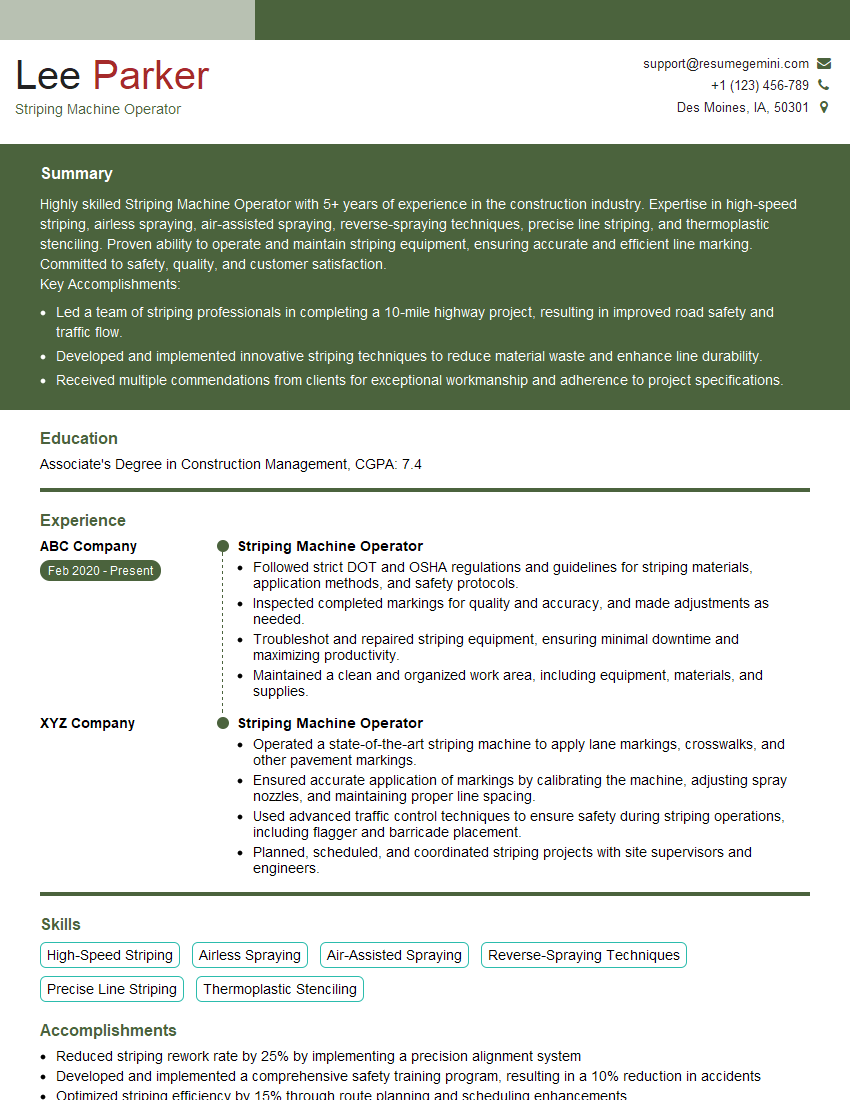

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Striping Machine Operator

1. Describe the key responsibilities of a Striping Machine Operator.

The key responsibilities of a Striping Machine Operator typically include:

- Preparing and operating a striping machine to apply paint or thermoplastic markings to roadways, parking lots, and other surfaces.

- Setting up and adjusting the machine to ensure proper alignment, coverage, and thickness of the markings.

- Maintaining the striping machine and its components to ensure optimal performance.

- Inspecting newly applied markings to ensure they meet quality standards and specifications.

- Working with other members of the road construction crew to ensure the safe and efficient completion of projects.

2. Explain the different types of striping materials and their applications.

There are several types of striping materials used for different applications, including:

Waterborne Paint

- Water-based, environmentally friendly option

- Provides good durability and visibility

- Suitable for most roadway applications

Thermoplastic

- Heat-applied material that forms a raised profile

- Excellent durability and skid resistance

- Typically used for high-traffic areas and intersections

Methyl Methacrylate (MMA)

- Fast-drying, durable material

- Can be applied in a wide range of temperatures

- Often used for temporary or emergency markings

Epoxies

- Two-component material that provides excellent adhesion and durability

- Resistant to chemicals and abrasion

- Used for heavy-duty applications, such as industrial floors and parking garages

3. Describe the safety precautions that must be taken when operating a striping machine.

Operating a striping machine requires adhering to strict safety precautions, including:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and ear protection.

- Ensuring the work area is properly ventilated to prevent exposure to harmful fumes.

- Maintaining a safe distance from traffic and pedestrians.

- Using traffic control devices to warn other motorists and pedestrians of the work zone.

- Following all manufacturer’s instructions and safety protocols for operating the striping machine.

4. Explain how you would troubleshoot a striping machine that is not applying paint or thermoplastic evenly.

When a striping machine is not applying paint or thermoplastic evenly, I would troubleshoot the following:

- Check the material supply and ensure it is flowing properly.

- Inspect the spray nozzle or applicator for any clogs or blockages.

- Examine the pump and pressure settings to ensure they are calibrated correctly.

- Check the alignment of the machine to ensure it is applying material in the desired direction and at the appropriate angle.

- Review the manufacturer’s specifications for the machine and follow the recommended maintenance and calibration procedures.

5. Describe the different techniques used to achieve different types of striping line styles, such as solid, dashed, and skip lines.

Different line styles are achieved by controlling the flow of paint or thermoplastic through the striping machine:

Solid Lines

- Continuous flow of material

- Used for lane lines, edge lines, and stop lines

Dashed Lines

- Controlled flow of material, resulting in alternating dashes and gaps

- Used for lane separators, merge areas, and crosswalks

Skip Lines

- Intermittent flow of material, resulting in short dashes followed by longer gaps

- Used for pavement markings to indicate areas where parking or stopping is prohibited

6. Explain the importance of proper line spacing and thickness when striping a roadway or parking lot.

Proper line spacing and thickness are crucial for several reasons:

- Ensures visibility and clarity of traffic markings for drivers and pedestrians.

- Facilitates safe and orderly traffic flow.

- Complies with industry standards and regulations.

- Improves the aesthetics of the roadway or parking lot.

7. Describe the different types of reflective materials used in striping and their benefits.

Reflective materials are used in striping to enhance visibility and safety, including:

Glass Beads

- Small, glass spheres that reflect light back to its source

- Provide good retroreflectivity at night and in low-light conditions

Ceramic Beads

- Ceramic-based spheres that offer higher retroreflectivity than glass beads

- Durable and resistant to wear and tear

Thermoplastic Raised Markers

- Raised, reflective markers that provide excellent visibility and guidance

- Used for traffic signs, lane lines, and other high-visibility applications

8. Explain how you would maintain a striping machine to ensure optimal performance and longevity.

To maintain a striping machine for optimal performance and longevity, I would:

- Clean the machine thoroughly after each use, removing any paint or thermoplastic residue.

- Inspect the spray nozzle or applicator for any wear or damage.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Check the pump and pressure settings regularly to ensure proper operation.

- Follow the manufacturer’s maintenance schedule for more comprehensive inspections and servicing.

9. Describe the different methods used to measure and mark pavement before striping.

Before striping, pavement markings are measured and marked using various methods:

Tape Measure and Chalk Line

- Traditional method involving measuring distances and marking lines with chalk

Layout Machine

- Specialized equipment that automatically measures and marks pavement using lasers or other sensors

Total Station

- Surveying instrument that utilizes precise measurements and angles to mark pavement accurately

GPS (Global Positioning System)

- Satellite-based technology that provides accurate positioning data for marking pavement

10. Explain how you would deal with unexpected challenges or emergencies while operating a striping machine.

When faced with unexpected challenges or emergencies while operating a striping machine, I would:

- Remain calm and assess the situation.

- Stop the machine immediately and secure the area if necessary.

- Contact my supervisor or project manager to report the issue.

- Follow established safety protocols and cooperate with emergency responders if required.

- Document the incident and take steps to prevent similar occurrences in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Striping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Striping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Striping Machine Operators are responsible for operating and maintaining stripping machines used to remove old or damaged paint, coatings, or finishes from various surfaces. They play a crucial role in preparing surfaces for new coatings or finishes, ensuring a smooth and professional-looking result.

1. Machine Operation

Operate striping machines according to established procedures and safety regulations.

- Load and unload workpieces into and out of the machine correctly.

- Adjust machine settings to achieve optimal stripping results.

2. Surface Preparation

Prepare surfaces for stripping by cleaning and removing any contaminants.

- Mask off or protect areas that should not be stripped.

- Select appropriate stripping chemicals and abrasives.

3. Quality Control

Inspect stripped surfaces to ensure the desired level of removal has been achieved.

- Monitor stripping progress and make adjustments as needed.

- Identify and correct any defects or inconsistencies.

4. Machine Maintenance

Perform routine maintenance on stripping machines to ensure optimal performance.

- Clean and lubricate machine components regularly.

- Replace worn or damaged parts as necessary.

Interview Tips

Preparing thoroughly for a Striping Machine Operator interview can significantly increase your chances of success. Here are some valuable tips and strategies to help you ace your interview:

1. Research the Company and Position

Thoroughly research the company you’re applying to, including their industry, products or services, and company culture. Also, familiarize yourself with the specific job description and responsibilities of the Striping Machine Operator position.

- Visit the company’s website and social media pages.

- Read industry news and articles related to stripping and surface preparation.

2. Highlight Relevant Skills and Experience

In your resume and interview, emphasize your relevant skills and experience that align with the job requirements. Focus on highlighting your proficiency in operating and maintaining stripping machines, as well as your knowledge of surface preparation techniques.

- Quantify your accomplishments with specific examples whenever possible.

- Use keywords from the job description in your resume and interview responses.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the interview. Some common questions you may encounter include:

- “Tell me about your experience operating stripping machines.”

- “How do you prepare surfaces for stripping?”

- “What are the different types of stripping chemicals and abrasives, and when do you use each type?”

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally for your interview. Additionally, punctuality demonstrates respect for the interviewer’s time and sends a positive message about your work ethic.

- Choose attire that is clean, pressed, and appropriate for the industry and company culture.

- Arrive on time for your interview and be prepared to start promptly.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. This is an opportunity to learn more about the company, the role, and the expectations.

- Prepare questions that are specific and relevant to the job.

- Avoid asking questions that can be easily answered by reading the job description or company website.

Next Step:

Now that you’re armed with the knowledge of Striping Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Striping Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini