Are you gearing up for a career in 2nd Pressman? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for 2nd Pressman and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

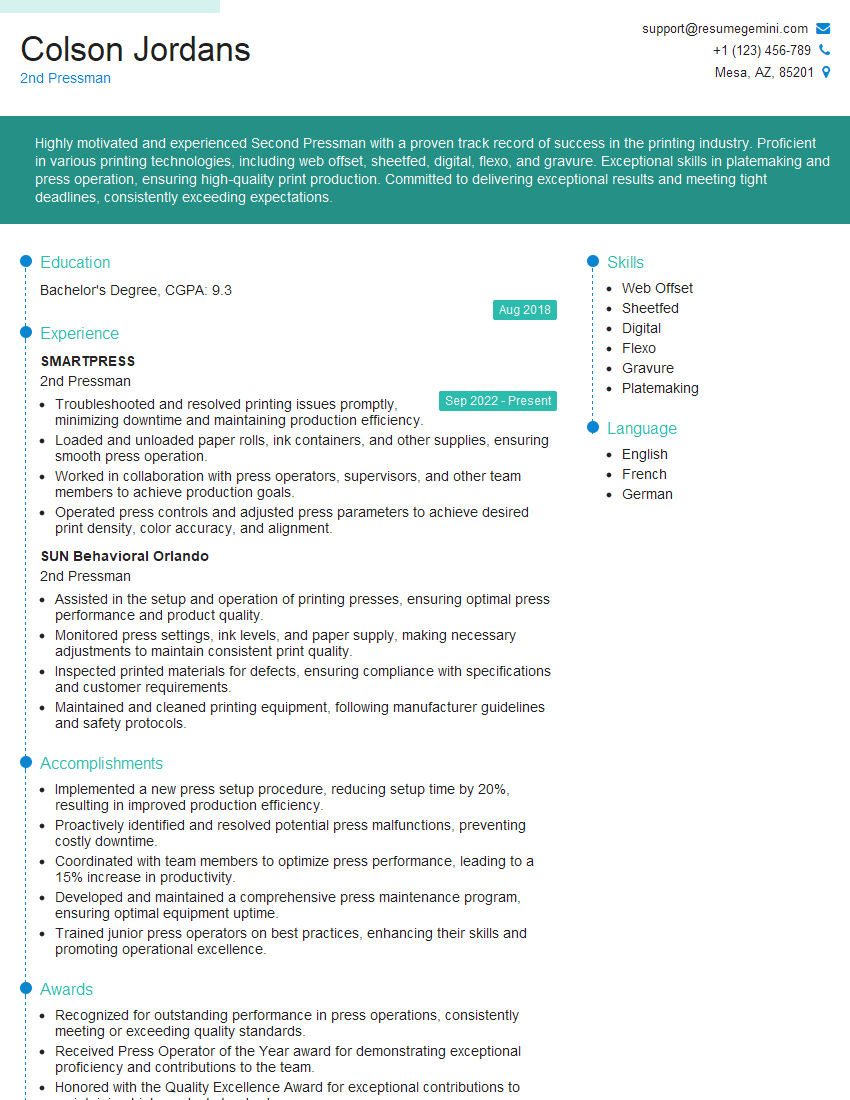

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For 2nd Pressman

1. Describe the process of preparing a printing press for operation?

- Inspect the press and its components for any damage or malfunction.

- Clean the press bed, rollers, and ink system to remove any debris or contamination.

- Load the paper stock into the press and adjust the settings to ensure proper alignment and registration.

- Set up the ink fountain and adjust the ink flow to achieve the desired print quality.

- Adjust the press speed, pressure, and other parameters based on the specific printing job requirements.

2. How do you troubleshoot and resolve common printing problems such as smearing, ghosting, or uneven ink distribution?

- Smearing: Check for excessive ink flow, uneven pressure, or worn rollers.

- Ghosting: Adjust the impression pressure or drying time, or check for paper moisture issues.

- Uneven ink distribution: Clean the ink fountain and rollers, adjust the ink flow, or replace the ink if necessary.

3. Explain the different types of paper stocks used in printing and their suitability for various applications?

- Offset paper: Uncoated, versatile, and suitable for general printing purposes.

- Coated paper: Smooth, glossy, and provides high-quality print results.

- Specialty papers: Textured, metallic, or recycled, used for special effects or environmental considerations.

4. How do you maintain and calibrate the printing press to ensure consistent print quality?

- Regularly clean and lubricate the press components to prevent wear and tear.

- Calibrate the ink system to maintain consistent ink flow and color reproduction.

- Inspect and replace worn or damaged rollers, blankets, and other components as needed.

5. Can you describe the safety protocols and regulations that must be followed when operating a printing press?

- Wear appropriate safety gear, including gloves, eye protection, and a mask.

- Ensure proper ventilation to prevent ink fumes or dust inhalation.

- Follow lockout/tagout procedures when servicing or repairing the press.

6. What measures can you take to minimize waste and promote sustainability in the printing process?

- Use recycled paper or paper with a high post-consumer waste content.

- Optimize ink usage and reduce overinking.

- Recycle printing waste, including paper, ink cartridges, and plates.

7. How do you stay up-to-date with advancements in printing technology and best practices?

- Attend industry workshops, conferences, and trade shows.

- Read technical journals and online resources.

- Seek training from manufacturers or equipment suppliers.

8. Describe your experience with different printing techniques, such as offset, digital, or flexography?

- Offset printing: Knowledge of press setup, ink management, and paper handling.

- Digital printing: Familiarity with digital press operation, file preparation, and color management.

- Flexography: Experience with platemaking, ink transfer, and substrate flexibility.

9. How do you handle and store printing materials, such as inks, solvents, and paper, to ensure their quality and prevent spoilage?

- Store inks in a cool, dry place to prevent viscosity changes.

- Keep solvents in sealed containers and follow proper disposal procedures.

- Protect paper from moisture, temperature fluctuations, and direct sunlight.

10. What quality control measures do you implement to ensure the accuracy and consistency of printed materials?

- Regularly inspect printed samples for color accuracy, registration, and overall quality.

- Use color charts and measuring devices to ensure color consistency.

- Establish and follow print specifications and quality standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for 2nd Pressman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the 2nd Pressman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a 2nd Pressman, the core responsibilities revolve around operating and maintaining printing presses, ensuring the production of high-quality printed materials. The role encompasses various tasks related to press preparation, operation, and troubleshooting.

1. Press Setup and Preparation

Initiate the printing process by setting up the press according to production specifications and customer requirements.

- Mount printing plates accurately and securely

- Adjust and calibrate press settings for optimal print quality

2. Press Operation

Monitor and control the printing press during operation to ensure smooth and efficient production.

- Load and adjust paper stock as per job requirements

- Monitor ink flow and make necessary adjustments to maintain color consistency

3. Troubleshooting and Maintenance

Identify and resolve press-related issues promptly to minimize downtime and maintain production efficiency.

- Troubleshoot and rectify printing defects such as ink smudging or improper registration

- Perform routine maintenance tasks to ensure press is operating at peak performance

4. Quality Control

Inspect printed materials to ensure they meet established quality standards and customer specifications.

- Monitor color accuracy, sharpness, and consistency

- Identify and report any quality deviations or issues

Interview Tips

To ace the interview for a 2nd Pressman position, it’s crucial to prepare thoroughly and demonstrate your technical skills, attention to detail, and problem-solving abilities.

1. Research the Company and the Role

Familiarize yourself with the printing company and its products or services. Understand the specific requirements and responsibilities of the 2nd Pressman role.

- Visit the company website and review their portfolio

- Research industry trends and best practices related to printing

2. Highlight Your Technical Skills

Emphasize your expertise in operating and maintaining printing presses. Quantify your experience and demonstrate your knowledge of different printing processes.

- Discuss your experience in setting up and calibrating printing presses

- Describe your ability to troubleshoot and resolve common press issues

3. Showcase Your Attention to Detail

Highlight your attention to detail and quality-oriented approach. Explain how you ensure the accuracy and consistency of printed materials.

- Provide examples of how you have identified and corrected quality deviations

- Explain your understanding of color management and color accuracy

4. Emphasize Your Problem-Solving Abilities

Demonstrate your ability to identify and resolve press-related issues effectively. Share examples of how you have overcome challenges and improved production efficiency.

- Describe a situation where you identified a printing defect and implemented a solution

- Explain how you have optimized press performance through preventive maintenance

5. Prepare for Common Interview Questions

Familiarize yourself with common interview questions related to the printing industry and the 2nd Pressman role. Practice answering these questions concisely and confidently.

- Why are you interested in working as a 2nd Pressman?

- What is your experience with different types of printing presses?

- How do you handle press-related issues that require immediate attention?

- How do you ensure the quality and accuracy of printed materials?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a 2nd Pressman, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for 2nd Pressman positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.