Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bag Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

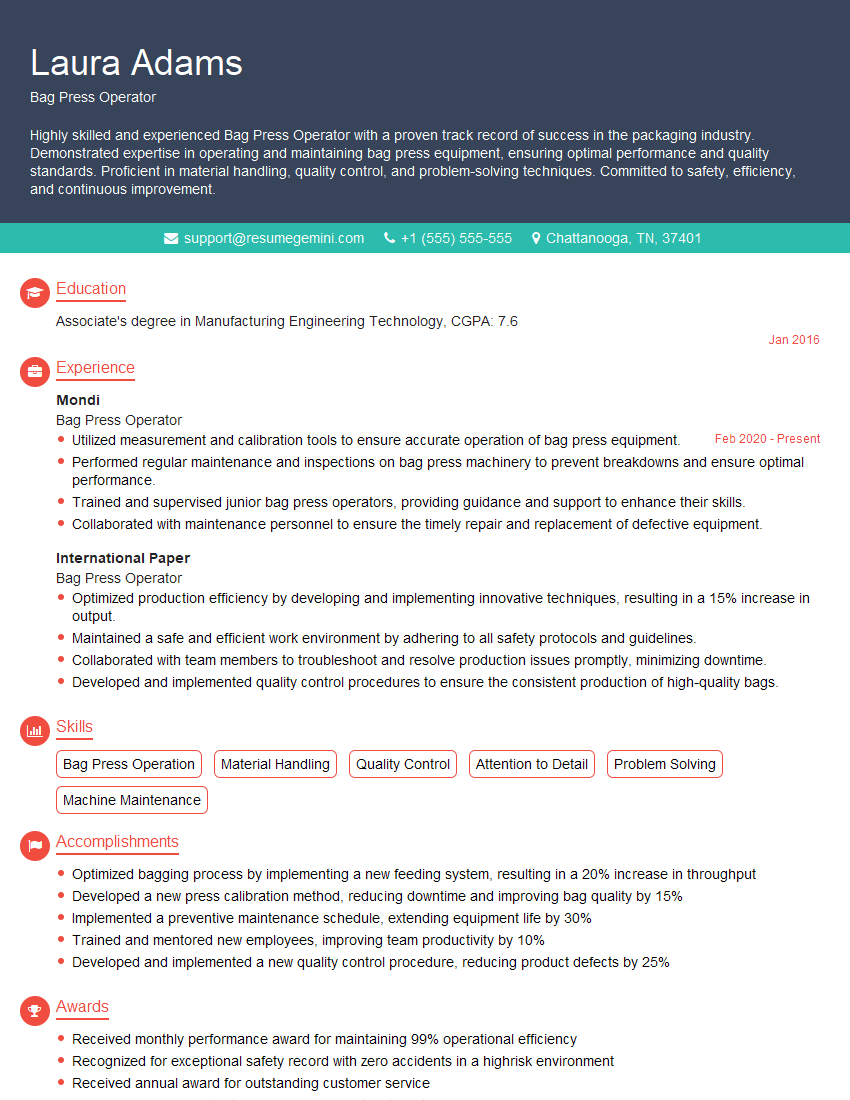

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bag Press Operator

1. Explain the steps involved in the bag pressing process?

The steps involved in the bag pressing process are:

- Prepare the bagging area.

- Load the bags onto the bag press.

- Press the bags.

- Unload the bags from the bag press.

- Clean the bag press.

2. What are the different types of bag presses?

Hydraulic bag presses

- Use hydraulic pressure to press the bags.

- Are very powerful and can press large bags.

Mechanical bag presses

- Use mechanical force to press the bags.

- Are less powerful than hydraulic bag presses, but are also less expensive.

Pneumatic bag presses

- Use air pressure to press the bags.

- Are very fast and can press multiple bags at once.

3. What are the safety precautions that must be taken when operating a bag press?

The safety precautions that must be taken when operating a bag press are:

- Never operate a bag press without proper training.

- Always wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Never place your hands or fingers inside the bag press while it is operating.

- Never attempt to repair or adjust a bag press while it is operating.

- Always follow the manufacturer’s instructions for operating the bag press.

4. What are the common problems that can occur with bag presses?

The common problems that can occur with bag presses are:

- Bag jams.

- Hydraulic leaks.

- Electrical problems.

- Mechanical failures.

5. How do you troubleshoot a bag press?

To troubleshoot a bag press, you should:

- Check for bag jams.

- Check for hydraulic leaks.

- Check for electrical problems.

- Check for mechanical failures.

6. What is the difference between a bag press and a baler?

A bag press is used to compress bags of material, while a baler is used to compress bales of material.

- Bag presses are typically used for smaller bags of material, while balers are used for larger bales of material.

- Bag presses are typically less expensive than balers.

7. What are the benefits of using a bag press?

The benefits of using a bag press are:

- Increased efficiency.

- Reduced labor costs.

- Improved safety.

- Reduced waste.

8. What are the different types of materials that can be pressed with a bag press?

The different types of materials that can be pressed with a bag press include:

- Paper.

- Cardboard.

- Plastic.

- Metal.

9. What is the maximum weight that a bag press can handle?

The maximum weight that a bag press can handle depends on the size and type of bag press.

- Small bag presses can handle weights of up to 1,000 pounds.

- Large bag presses can handle weights of up to 10,000 pounds.

10. What is the maintenance schedule for a bag press?

The maintenance schedule for a bag press depends on the size and type of bag press.

- Small bag presses should be inspected and cleaned monthly.

- Large bag presses should be inspected and cleaned weekly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bag Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bag Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bag Press Operators work in manufacturing plants, typically in the food and beverage industry, to operate and maintain bag pressing machines that package products into flexible bags. They perform various tasks to ensure efficient and safe production.

1. Machine Operation

Bag Press Operators are responsible for setting up, operating, and maintaining the bag pressing machine. This includes loading empty bags onto the machine, adjusting machine settings to meet production specifications, and monitoring the machine to ensure proper operation.

- Load empty bags onto the machine

- Adjust machine settings to meet production specifications

- Monitor the machine to ensure proper operation

2. Bag Formation

Bag Press Operators ensure that the bags are properly formed and filled with the correct amount of product. This may involve manually inserting liner bags into the machine, making sure the bag is properly positioned on the conveyor belt, and checking the bag for defects after it has been filled.

- Manually insert liner bags into the machine

- Position the bag properly on the conveyor belt

- Check the bag for defects after it has been filled

3. Product Handling

Bag Press Operators are also responsible for handling the product being packaged. This may involve loading product into the filler machine, inspecting the product for foreign objects or contaminants, and monitoring the product flow to ensure the correct fill weight.

- Loading product into the filler machine

- Inspecting the product for foreign objects or contaminants

- Monitor the product flow to ensure the correct fill weight

4. Quality Control

Bag Press Operators are responsible for conducting quality control checks to ensure that the packaged product meets the required standards. This may involve checking the weight of the filled bags, inspecting the bags for leaks or damage, and checking the product for any signs of contamination.

- Checking the weight of the filled bags

- Inspecting the bags for leaks or damage

- Checking the product for any signs of contamination

Interview Tips

Preparing thoroughly for a job interview can significantly improve your chances of making a positive impression and landing the job. Here are some essential interview tips for a Bag Press Operator position:

1. Research the Company and Position

Take the time to research the company you are applying for and the specific Bag Press Operator position. This will help you understand the company’s culture, values, and the requirements of the job. You can gather this information by visiting the company’s website, reading industry news and articles, or talking to people who work or have worked there.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work or have worked there

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, regardless of the position you are applying for. These questions often focus on your skills, experience, and qualifications. It is important to practice answering these questions in a clear and concise manner.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Highlight Relevant Skills and Experience

In your interview, be sure to highlight the skills and experience that are most relevant to the Bag Press Operator position. This may include your experience operating and maintaining bag pressing machines, your knowledge of quality control procedures, and your ability to work in a fast-paced environment.

- Experience operating and maintaining bag pressing machines

- Knowledge of quality control procedures

- Ability to work in a fast-paced environment

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Dress professionally

- Arrive on time

5. Be Yourself and Be Confident

It is important to be yourself and be confident during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities and in your ability to do the job. Believe in Yourself.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bag Press Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.