Are you gearing up for an interview for a Embossing Press Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Embossing Press Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

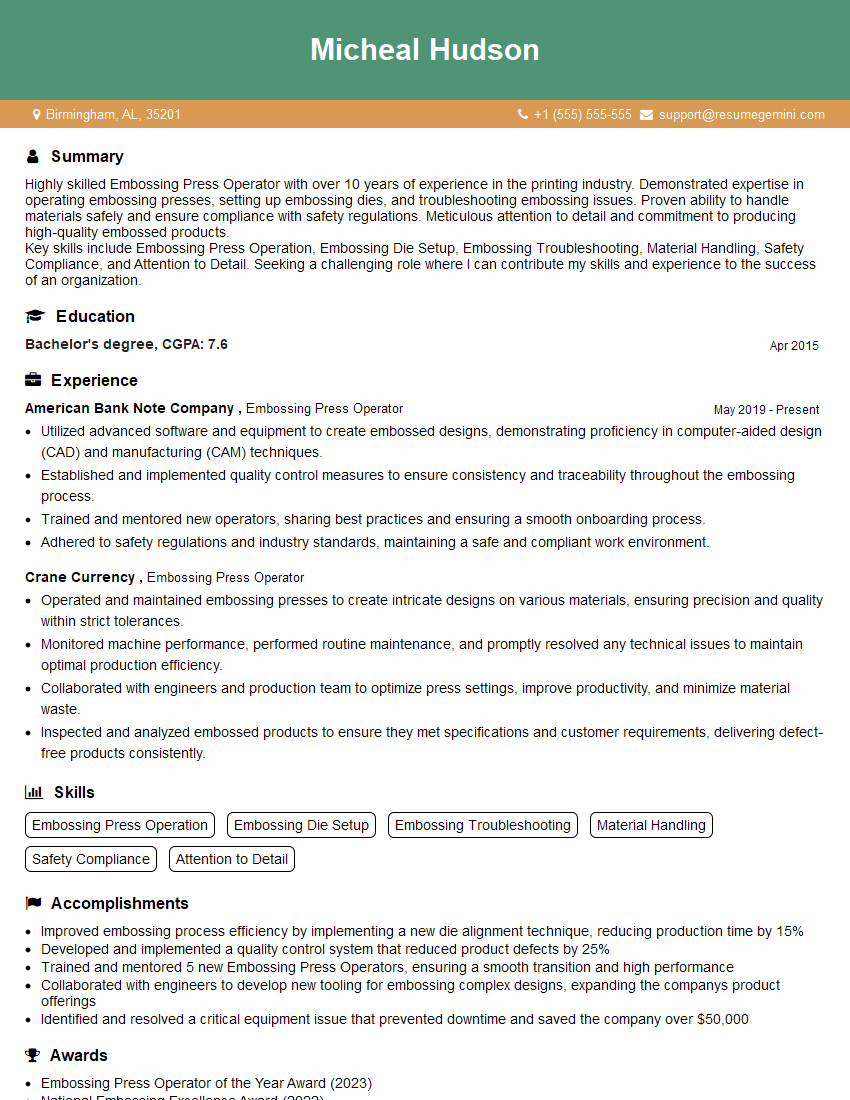

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Embossing Press Operator

1. What are the different types of embossing presses you have operated?

I have operated a variety of embossing presses, including manual, semi-automatic, and fully automatic presses. I am also familiar with different types of dies and materials used in embossing.

2. What are the key factors to consider when setting up an embossing press?

Die selection

- The type of die used will depend on the desired embossing effect and the material being embossed.

- The die must be properly aligned and secured to ensure accurate and consistent embossing.

Pressure and temperature

- The pressure and temperature used during embossing must be carefully controlled to achieve the desired effect without damaging the material.

- The ideal pressure and temperature will vary depending on the material, die, and desired result.

Speed and dwell time

- The speed and dwell time of the press must be adjusted to ensure that the material is embossed evenly and completely.

- The ideal speed and dwell time will depend on the material, die, and desired result.

3. How do you troubleshoot common problems that arise during embossing?

Some common problems that can arise during embossing include:

- Uneven or incomplete embossing: This can be caused by improper die alignment, incorrect pressure or temperature, or insufficient dwell time.

- Material damage: This can be caused by excessive pressure, temperature, or speed.

- Die wear: Dies can wear over time, which can lead to reduced embossing quality.

To troubleshoot these problems, I would first check the die alignment, pressure, temperature, and dwell time. I would also inspect the die for wear and damage. Once the problem has been identified, I would make the necessary adjustments to the press or replace the die.

4. What are the safety precautions that must be taken when operating an embossing press?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Keep hands and other body parts away from the moving parts of the press.

- Never operate the press if it is not properly guarded.

- Inspect the press and dies regularly for wear or damage.

- Follow all manufacturer’s instructions for safe operation.

5. What are your quality control procedures for ensuring that embossed products meet specifications?

My quality control procedures for ensuring that embossed products meet specifications include:

- Visual inspection: I visually inspect each embossed product to check for any defects, such as uneven or incomplete embossing, material damage, or die wear.

- Dimensional inspection: I use a micrometer or other measuring tool to verify that the embossed product meets the required dimensions.

- Performance testing: I perform performance tests to ensure that the embossed product meets the required specifications for strength, durability, and other factors.

I maintain detailed records of all quality control inspections and tests. This documentation helps me to identify any trends or problems that need to be addressed.

6. What is your experience with preventive maintenance for embossing presses?

I have experience with preventive maintenance for embossing presses, including:

- Regularly cleaning and lubricating the press and dies.

- Inspecting the press and dies for wear or damage.

- Tightening any loose bolts or screws.

- Replacing worn or damaged parts.

- Calibrating the press to ensure accuracy.

By performing preventive maintenance on a regular basis, I can help to extend the life of the press and dies, improve product quality, and reduce downtime.

7. What is your understanding of the different types of materials that can be embossed?

Different types of materials that can be embossed include:

- Paper: Paper is a common material for embossing because it is relatively thin and easy to shape.

- Cardboard: Cardboard is thicker and more durable than paper, making it suitable for more heavy-duty applications.

- Plastic: Plastic is a versatile material that can be embossed with a variety of designs.

- Metal: Metal can be embossed to create intricate designs and patterns.

- Leather: Leather is a durable material that can be embossed to create a variety of textures and designs.

The type of material being embossed will affect the die design, pressure, temperature, and speed used during the embossing process.

8. What are the latest trends and developments in embossing technology?

Some of the latest trends and developments in embossing technology include:

- Digital embossing: Digital embossing uses computer-controlled technology to create embossed designs.

- 3D embossing: 3D embossing creates three-dimensional embossed designs.

- Laser embossing: Laser embossing uses a laser to create embossed designs.

- Holographic embossing: Holographic embossing creates embossed designs that appear to change when viewed from different angles.

These new technologies are expanding the possibilities for embossing and creating new opportunities for businesses.

9. What is your experience with working in a team environment?

I have experience working in a team environment in a variety of settings, including in previous manufacturing roles. I am a team player and I am always willing to contribute my skills and knowledge to help the team achieve its goals. I am also a good communicator and I am able to work effectively with people from diverse backgrounds.

10. Why are you interested in working for our company?

I am interested in working for your company because I am impressed by your commitment to quality and innovation. I believe that my skills and experience would be a valuable asset to your team. I am also eager to learn more about the latest trends and developments in embossing technology and I believe that working for your company would provide me with the opportunity to do so.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Embossing Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Embossing Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Embossing Press Operator plays a vital role in the production and quality of embossed products. The job requires a combination of technical expertise, attention to detail, and operational efficiency.

1. Machine Operation and Maintenance

Operate embossing press machines to create precise and consistent designs on materials.

- Set up and calibrate machines according to product specifications.

- Monitor machine performance, identify potential issues, and perform routine maintenance.

2. Material Handling

Handle and feed materials into the press machine, ensuring proper alignment and positioning.

- Inspect materials for defects and determine appropriate processing parameters.

- Unload and inspect finished products, ensuring they meet quality standards.

3. Die Selection and Installation

Select and install appropriate dies or tooling to produce the desired embossing pattern.

- Understand die specifications and ensure proper alignment and pressure.

- Inspect dies for wear and damage, and perform necessary repairs or replacements.

4. Quality Control

Conduct regular quality checks on embossed products to ensure they adhere to specifications.

- Identify and correct any defects or inconsistencies in the embossing process.

- Maintain detailed records of quality control measures and product inspections.

Interview Tips

Preparing for an interview for an Embossing Press Operator position requires a blend of technical knowledge and a demonstration of practical skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Role

Familiarise yourself with the company’s background, products, and industry. Understand the specific responsibilities and requirements of the Embossing Press Operator role.

- Visit the company website, read industry publications, and consult with professionals in the field.

- Identify areas where your skills and experience align with the job description.

2. Highlight Relevant Skills and Experience

Emphasise your proficiency in operating embossing press machines, handling materials, and maintaining equipment. Quantify your experience and provide specific examples of your contributions.

- Describe the types of embossing machines you have operated and the materials you have worked with.

- Share your knowledge of die selection, installation, and maintenance procedures.

3. Demonstrate Attention to Detail and Quality

Embossing Press Operators must possess a keen eye for detail and a commitment to quality. Highlight your ability to identify and correct defects, maintain consistent production, and adhere to specifications.

- Provide examples of how you have implemented quality control measures in previous roles.

- Describe your understanding of the importance of precision and accuracy in the embossing process.

4. Emphasise Problem-Solving Abilities

Embossing machines can encounter various issues. Demonstrate your problem-solving skills and ability to identify and resolve potential challenges.

- Share experiences where you diagnosed and repaired machine malfunctions.

- Explain your approach to troubleshooting and optimising production processes.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Embossing Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.