Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Engraver Set-Up Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Engraver Set-Up Operator so you can tailor your answers to impress potential employers.

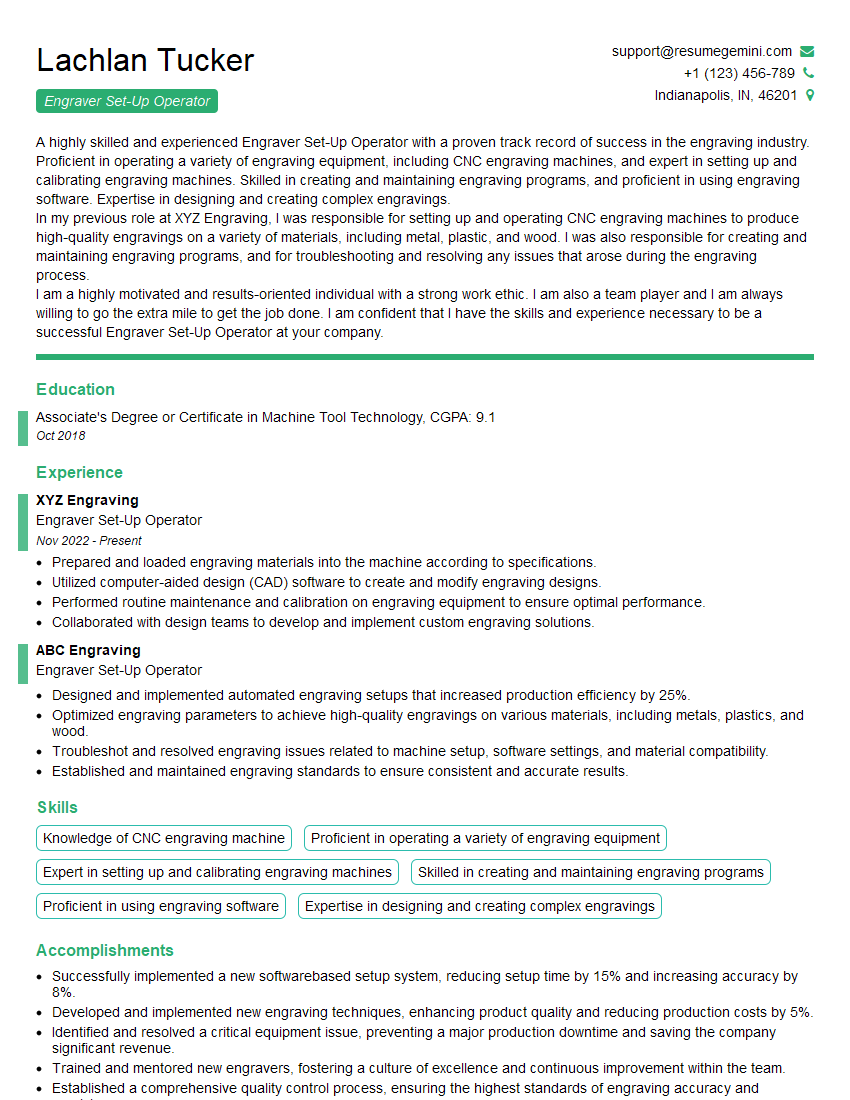

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Engraver Set-Up Operator

1. Describe the process of setting up an engraving machine?

Here is a detailed process of setting up an engraving machine:

- Secure the workpiece: Clamp or otherwise secure the workpiece to the machine’s table.

- Choose the correct engraving tool: Select the appropriate engraving tool based on the material and desired engraving depth.

- Set the engraving depth: Determine and set the desired engraving depth using the machine’s controls.

- Align the tool: Position the engraving tool correctly over the workpiece, ensuring alignment with the desired engraving area.

- Calibrate the machine: Run a test engraving to calibrate the machine’s settings and ensure optimal engraving quality.

2. How do you determine the correct engraving speed and feed rate for a given material?

To determine the correct engraving speed and feed rate for a given material, I consider the following factors and make adjustments accordingly:

- Material hardness: Harder materials require slower engraving speeds and higher feed rates.

- Engraving depth: Deeper engravings require slower engraving speeds and higher feed rates.

- Engraving tool: Different engraving tools have optimal speed and feed rate ranges.

- Machine capabilities: The maximum engraving speed and feed rate are also limited by the engraving machine.

- Test engraving: Performing a test engraving helps fine-tune the settings for the best engraving quality.

3. What are the different types of engraving techniques and when is each one used?

The most common engraving techniques are:

- Laser engraving: Uses a laser beam to engrave designs or text, resulting in precise and permanent markings.

- Mechanical engraving: Uses a rotating cutter to engrave designs or text, offering versatility and durability.

- Chemical engraving: Uses chemical etching to create engravings, suitable for intricate designs on delicate materials.

- Sandblasting: Uses a stream of abrasive particles to engrave designs or text, ideal for creating textured or frosted effects.

- Electrochemical engraving: Uses an electrochemical process to create engravings, providing high precision and detail.

4. How do you troubleshoot common engraving problems, such as uneven engraving or broken tools?

To troubleshoot common engraving problems, I follow these steps:

- Uneven engraving: Check the engraving tool’s sharpness, adjust the engraving depth, and ensure proper alignment.

- Broken tools: Inspect the engraving tool for damage, replace it if necessary, and verify that the machine’s settings are within the tool’s specifications.

- Poor engraving quality: Clean the engraving area, adjust the engraving speed and feed rate, and experiment with different engraving techniques.

- Machine malfunctions: Check for any mechanical or electrical issues, consult the machine’s maintenance manual, and contact technical support if needed.

5. How do you ensure the safety of yourself and others when operating an engraving machine?

To ensure a safe work environment, I adhere to the following safety measures when operating an engraving machine:

- Wear appropriate safety gear: Use eye protection, gloves, and proper clothing to protect against hazards.

- Secure the workpiece: Ensure that the workpiece is securely clamped to the machine’s table to prevent movement or accidents.

- Follow machine instructions: Operate the engraving machine according to the manufacturer’s instructions and safety guidelines.

- Be aware of surroundings: Pay attention to others in the work area and maintain a safe distance from moving parts.

- Proper ventilation: Ensure adequate ventilation to remove fumes or dust generated during engraving.

6. What is your experience with different types of engraving software?

I have experience working with the following engraving software:

- Laser engraving software: RDWorks, LightBurn, EzCad

- Mechanical engraving software: Vectric Aspire, Cut2D, Mach3

- Other engraving software: CorelDRAW, Inkscape, Adobe Illustrator

7. How do you handle complex engraving projects that require multiple passes or intricate designs?

To handle complex engraving projects, I follow these steps:

- Project planning: Carefully review the project requirements and break down the engraving tasks into smaller steps.

- Artwork preparation: Create or modify the artwork to ensure it meets the machine’s specifications and engraving parameters.

- Multiple passes: Divide the engraving process into multiple passes to achieve the desired depth and detail.

- Test engraving: Perform test engravings to optimize engraving settings and ensure accuracy before full production.

- Continuous monitoring: Monitor the engraving process closely to make adjustments as needed.

8. What is your approach to quality control in engraving?

I maintain quality control in engraving by:

- Regular machine calibration: Calibrate the engraving machine regularly to ensure precision and accuracy.

- Visual inspection: Inspect engraved pieces for defects, such as uneven lines, broken edges, or incorrect dimensions.

- Dimensional measurement: Use measuring tools to verify the accuracy of engraved dimensions and tolerances.

- Customer feedback: Seek feedback from clients to identify areas for improvement and maintain high levels of customer satisfaction.

9. How do you stay up-to-date with the latest engraving technologies and industry best practices?

To stay up-to-date with the latest engraving technologies and industry best practices, I:

- Attend industry events: Participate in conferences and exhibitions to learn about new technologies and network with experts.

- Online research: Read technical articles, industry blogs, and manufacturer websites to stay informed about advancements in engraving.

- Experimentation: Explore new engraving techniques and materials to expand my skills and knowledge.

- Collaboration: Engage with fellow engravers, share ideas, and learn from their experiences.

10. Describe a challenging engraving project you have completed and how you overcame the obstacles.

One challenging engraving project I completed was creating a highly detailed engraving on a delicate glass vase. The main obstacles were:

- Material fragility: The glass vase was thin and prone to breaking, requiring utmost care during handling and engraving.

- Intricate design: The design featured fine lines and small details, demanding precise engraving.

- Accuracy: The engraving needed to be aligned perfectly with the vase’s shape and curvature.

How I overcame the obstacles:

- Careful preparation: I secured the vase securely, used a sharp engraving tool, and tested the settings on a scrap piece of glass.

- Slow and steady approach: I engraved slowly and carefully, taking multiple passes to achieve the desired depth without damaging the glass.

- Regular inspection: I frequently checked the alignment and progress to ensure accuracy.

- Collaboration with experts: I consulted with a glass engraver to gain insights into the best techniques and avoid any potential risks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Engraver Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Engraver Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Engraver Set-Up Operator is responsible for preparing, setting up, and operating engraving machines to engrave designs and text on various materials. Their key job responsibilities include:

1. Machine Set-Up

Preparing the engraving machine by installing the appropriate engraving tools and accessories, such as spindles, engraving bits, and collets.

2. Material Preparation

Selecting and preparing engraving materials, such as metal, plastic, or wood, ensuring they are suitable for engraving and meet specified dimensions.

3. Design Programming

Interpreting and preparing engraving designs from digital files or other specifications, ensuring they align with the machine’s capabilities.

4. Engraving Execution

Operating the engraving machine to execute the design on the prepared material, maintaining accuracy, precision, and quality standards.

5. Machine Maintenance

Performing regular maintenance tasks to ensure the engraving machine operates smoothly, such as cleaning, lubrication, and minor repairs.

6. Quality Control

Inspecting engraved products to ensure they meet design specifications and customer requirements, identifying and correcting any defects or inconsistencies.

7. Safety Compliance

Observing safety protocols and procedures while operating engraving machinery, using appropriate safety gear, and adhering to established guidelines.

Interview Tips

Preparing thoroughly for an interview is crucial to impress potential employers and showcase your qualifications for the Engraver Set-Up Operator role. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and industry standing. Research the specific Engraver Set-Up Operator role, its responsibilities, and the company’s expectations.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience with engraving machines, including the types of machines you’ve operated and the materials you’ve worked with. Highlight your skills in design interpretation, quality control, and safety compliance.

3. Prepare for Technical Questions

Anticipate technical questions related to engraving processes, machine operation, and troubleshooting. Practice answering questions about engraving tools, materials, and software you’re familiar with. Be prepared to discuss your understanding of CNC (Computer Numerical Control) programming and machine maintenance.

4. Showcase Quality Control Measures

Explain your approach to quality control, including the inspection methods you use to ensure the accuracy and precision of engraved products. Highlight your attention to detail and commitment to delivering high-quality results.

5. Demonstrate Safety Awareness

Emphasize your knowledge of safety protocols and your commitment to adhering to them. Explain how you ensure a safe work environment while operating engraving machinery, including the use of appropriate safety gear and adherence to established guidelines.

6. Ask Thoughtful Questions

Asking insightful questions during the interview shows your engagement and interest in the role. Prepare questions about the company’s engraving processes, growth plans, and the opportunities for professional development within the organization.

7. Practice Your Responses

Practice answering common interview questions out loud or with a friend or family member. This will help you become more comfortable and articulate your responses during the actual interview.

8. Maintain a Positive and Professional Attitude

Throughout the interview, maintain a positive and professional demeanor. Be enthusiastic about the role, show confidence in your abilities, and demonstrate your eagerness to contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Engraver Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!