Feeling lost in a sea of interview questions? Landed that dream interview for Engraving Press Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Engraving Press Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

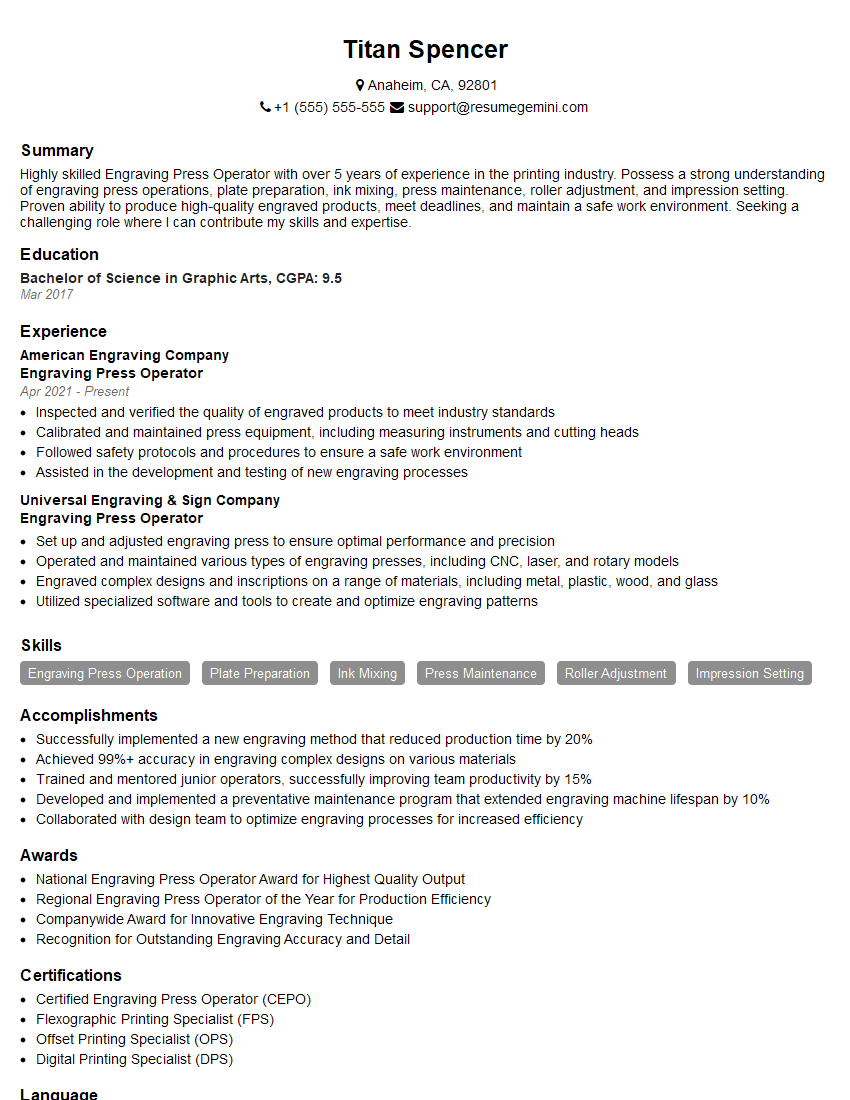

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Engraving Press Operator

1. What are the different types of engraving presses, and what are their advantages and disadvantages?

- Flatbed press: It is a press in which the print bed is flat, and the plate is placed on it similarly. It is suitable for small and medium-sized prints. The advantages of a flatbed press are that it is simple to operate, robust, and can produce high-quality prints. However, It can be slow and labor-intensive, and it can be difficult to achieve consistent registration.

- Cylinder press: The print bed is cylindrical, and the plate is wrapped around it. It is suitable for large prints. It is faster and more efficient than a flatbed press and can achieve more consistent registration. However, It can be more difficult to operate and maintain, and it can be more expensive.

- Rotary press: It is a type of cylinder press where the plate and impression cylinder are both rotating. It is used for high-speed printing of large quantities of prints. It is very fast and efficient and can achieve very consistent registration. However, It can be very expensive and complex to operate and maintain.

2. What are the different types of engraving tools, and how do you select the right tool for the job?

Factors to consider when selecting an engraving tool

- The material being engraved

- The desired depth and width of the engraving

- The speed and accuracy required

- The availability and cost of the tool

Types of engraving tools

- Hand-held engraving tools: These are the most common type of engraving tool and are used for small, detailed engravings. They are relatively inexpensive and easy to use.

- Machine engraving tools: These tools are used for larger, more complex engravings. They are more expensive than hand-held tools but can produce higher quality engravings.

- Laser engraving tools: These tools use a laser to engrave materials. They are very precise and can produce high-quality engravings. However, They can be expensive and require specialized training to operate.

3. How do you prepare a metal surface for engraving?

- Clean the surface with a solvent to remove any dirt or grease.

- Sand the surface with a fine-grit sandpaper to create a smooth, even surface.

- Mask off any areas of the surface that you do not want to engrave.

- Apply a resist to the surface to protect it from the engraving process.

4. What are the different types of engraving techniques, and how do you choose the right technique for the job?

- Line engraving: This technique is used to create lines in the metal surface. It can be done with a variety of tools, including a graver, a burin, or a diamond drag.

- Stipple engraving: This technique is used to create dots in the metal surface. It can be done with a variety of tools, including a punch, a needle, or a laser.

- Mezzotint engraving: This technique is used to create a tonal range in the metal surface. It is done with a rocker, which is a tool that creates small, evenly spaced dots in the metal surface.

- Drypoint engraving: This technique is used to create a soft, velvety look in the metal surface. It is done with a sharp needle or a diamond point.

5. How do you maintain an engraving press?

- Clean the press regularly with a solvent to remove any dirt or grease.

- Lubricate the press regularly with a light oil to keep it running smoothly.

- Check the press for any loose screws or bolts and tighten them as necessary.

- Inspect the press regularly for any signs of wear or damage and repair or replace any damaged parts as necessary.

6. What are the safety precautions that you must take when operating an engraving press?

- Wear eye protection and gloves when operating the press.

- Keep your hands away from the moving parts of the press.

- Do not operate the press if you are tired or under the influence of alcohol or drugs.

- Follow all of the manufacturer’s instructions for operating the press.

7. What are your three strengths as an Engraving Press Operator?

- Highly skilled in operating various types of engraving presses.

- Expertise in preparing metal surfaces for engraving.

- In-depth knowledge of different engraving techniques.

8. What are your two areas for improvement as an Engraving Press Operator?

- Improving speed and efficiency in operating the engraving press.

- Enhancing knowledge and skills in laser engraving techniques.

9. How do you stay up-to-date with the latest advancements in engraving technology?

- Attending industry trade shows and conferences.

- Reading trade publications and online resources.

- Consulting with equipment manufacturers and suppliers.

10. Why are you interested in working as an Engraving Press Operator for our company?

- Your company’s reputation for producing high-quality engraved products.

- The opportunity to work with a team of skilled and experienced professionals.

- The chance to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Engraving Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Engraving Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Engraving Press Operators are responsible for operating and maintaining engraving presses to create designs or inscriptions on a variety of materials, including metal, glass, plastic, and wood.

1. Operating Engraving Presses

Operate engraving presses to create designs or inscriptions on materials.

- Set up and adjust the engraving press according to specifications.

- Load and unload materials to be engraved.

- Monitor the engraving process and make adjustments as needed.

2. Maintaining Engraving Presses

Perform routine maintenance on engraving presses to ensure they are in good working condition.

- Clean and lubricate the press regularly.

- Inspect the press for any damage or wear and tear.

- Make minor repairs and adjustments as needed.

3. Creating and Designing Engravings

Create and design engravings based on customer specifications.

- Understand the customer’s requirements and translate them into a design.

- Use computer-aided design (CAD) software to create engraving patterns.

- Transfer the design to the engraving press.

4. Quality Control

Inspect the finished engravings and ensure they meet quality standards.

- Check the engravings for any defects or errors.

- Make any necessary corrections or adjustments.

- Ensure that the engravings meet the customer’s specifications.

Interview Tips

To ace an interview for an Engraving Press Operator position, it is important to prepare thoroughly and showcase your skills and experience.

1. Research the Company and the Position

Before the interview, research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals.

- Visit the company’s website to learn about their products, services, and mission.

- Read industry publications and news articles to stay up-to-date on the latest trends in engraving technology.

2. Practice Your Technical Skills

Engraving Press Operators need to have a strong understanding of engraving techniques and equipment. Practice your technical skills before the interview so that you can demonstrate your proficiency.

- If possible, get hands-on experience with different types of engraving presses.

- Review the safety protocols for operating engraving presses.

3. Highlight Your Experience

In your interview, be sure to highlight your experience and skills as an Engraving Press Operator. Quantify your accomplishments whenever possible.

- Provide examples of projects you have worked on and the results you achieved.

- Describe the different types of materials you have experience engraving.

4. Be Enthusiastic and Professional

Engraving Press Operators should be enthusiastic about their work and have a positive attitude. Show the interviewer that you are passionate about engraving and eager to learn new skills.

- Be polite and respectful to the interviewer.

- Dress professionally and arrive on time for your interview.

Next Step:

Now that you’re armed with the knowledge of Engraving Press Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Engraving Press Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini