Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Letterset Press Set-Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

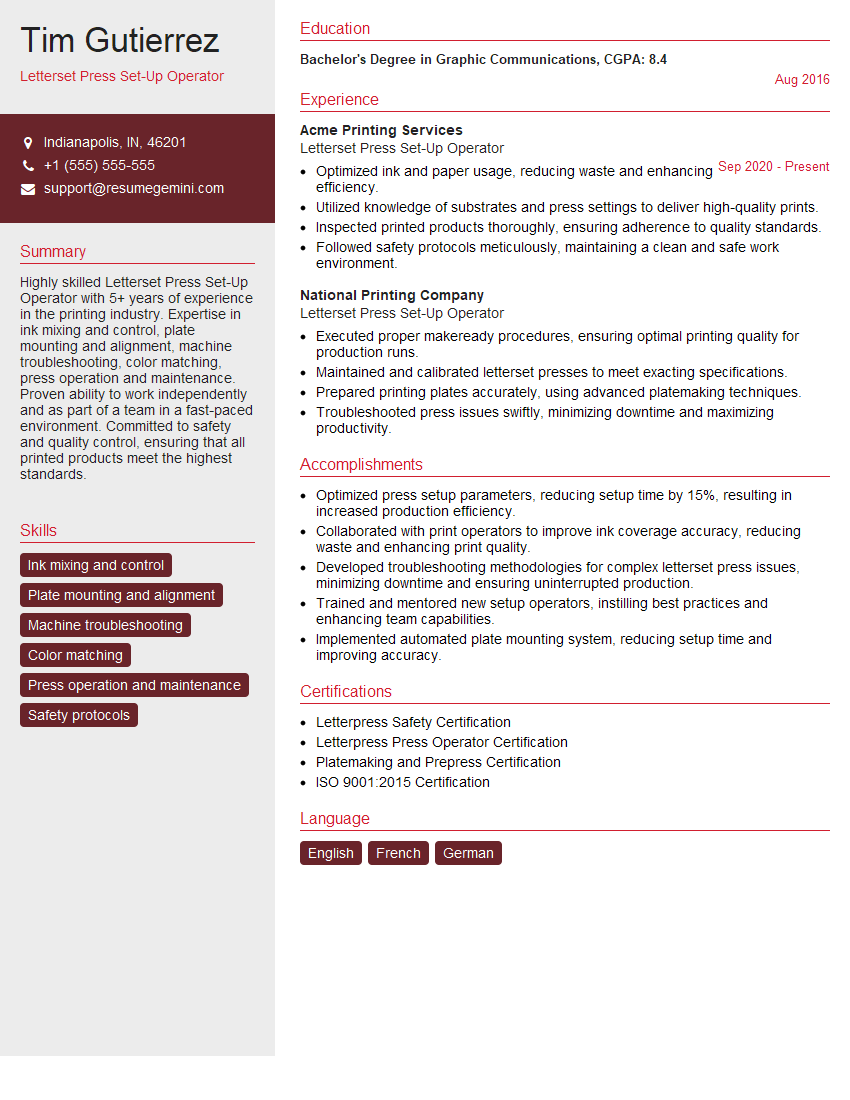

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Letterset Press Set-Up Operator

1. What are the key responsibilities of a Letterset Press Set-Up Operator?

As a Letterset Press Set-Up Operator, my key responsibilities include:

- Setting up and operating letterset printing presses

- Mounting printing plates on the press

- Adjusting press settings, such as ink flow and pressure

- Ensuring that the press is running smoothly and efficiently

- Troubleshooting and resolving any issues that may arise

2. What are the different types of letterset printing presses?

There are two main types of letterset printing presses:

Sheet-fed presses

- Print on individual sheets of paper

- Used for smaller print runs and higher-quality printing

Web presses

- Print on a continuous roll of paper

- Used for longer print runs and lower-quality printing

3. What are the different types of printing plates used in letterset printing?

The two main types of printing plates used in letterset printing are:

- Metal plates

- Polymer plates

4. What are the different types of inks used in letterset printing?

The two main types of inks used in letterset printing are:

- Oil-based inks

- Water-based inks

5. What are the different types of substrates used in letterset printing?

The most common types of substrates used in letterset printing are:

- Paper

- Cardboard

- Plastic

- Metal

6. What are the different types of finishing processes used in letterset printing?

The most common types of finishing processes used in letterset printing are:

- Die-cutting

- Embossing

- Foil stamping

- Laminating

- Varnishing

7. What are the different types of quality control checks that are performed in letterset printing?

The most common types of quality control checks that are performed in letterset printing are:

- Visual inspection

- Color measurement

- Registration check

- Density measurement

- Gloss measurement

8. What are the different types of safety precautions that must be taken when operating a letterset printing press?

The most common types of safety precautions that must be taken when operating a letterset printing press are:

- Wearing appropriate safety gear

- Following lockout/tagout procedures

- Being aware of the moving parts of the press

- Never putting your hands in the press while it is running

9. What are the different types of maintenance tasks that must be performed on a letterset printing press?

The most common types of maintenance tasks that must be performed on a letterset printing press are:

- Cleaning the press

- Oiling and greasing the press

- Checking the press for wear and tear

- Replacing worn or damaged parts

10. What are the different types of troubleshooting techniques that can be used to resolve problems with a letterset printing press?

The most common types of troubleshooting techniques that can be used to resolve problems with a letterset printing press are:

- Visual inspection

- Listening for unusual noises

- Checking the press for leaks

- Checking the press for electrical problems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Letterset Press Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Letterset Press Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Letterset Press Set-Up Operators are responsible for the setup and operation of letterset printing presses. They ensure that the press is running smoothly and efficiently, and that the printed products meet quality standards.

1. Preparing the Press for a New Job

This involves loading the paper into the press, setting up the ink and water levels, and making sure that the press is properly calibrated.

- Loading paper into the press

- Setting up the ink and water levels

- Calibrating the press

2. Monitoring the Press During Operation

This involves watching for any problems with the press, such as paper jams or ink smudging. The operator also needs to make sure that the printed products are meeting quality standards.

- Watching for paper jams

- Monitoring ink levels

- Checking the quality of the printed products

3. Troubleshooting and Repairing the Press

If a problem occurs with the press, the operator needs to be able to troubleshoot and repair it. This may involve replacing parts, adjusting the settings, or calling for maintenance.

- Replacing parts

- Adjusting the settings

- Calling for maintenance

4. Maintaining the Press

The operator is also responsible for maintaining the press. This involves cleaning the press, lubricating the moving parts, and making sure that the press is in good working order.

- Cleaning the press

- Lubricating the moving parts

- Inspecting the press for wear and tear

Interview Tips

To ace an interview for a Letterset Press Set-Up Operator position, it is important to be well-prepared. Here are some tips:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and the expectations for the role.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work in the industry

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions in advance so that you can deliver clear and concise responses.

- Prepare answers to common interview questions

- Practice your answers with a friend or family member

- Time yourself to make sure you can answer the questions within the time limit

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire

- Be on time for your interview

- Make eye contact and shake the interviewer’s hand firmly

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic about the position and who have a positive attitude. Be sure to show the interviewer that you are excited about the opportunity and that you are confident in your abilities.

- Smile and make eye contact

- Be positive and enthusiastic

- Show the interviewer that you are passionate about the printing industry

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Letterset Press Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!