Are you gearing up for a career in Lithograph Press Feeder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lithograph Press Feeder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

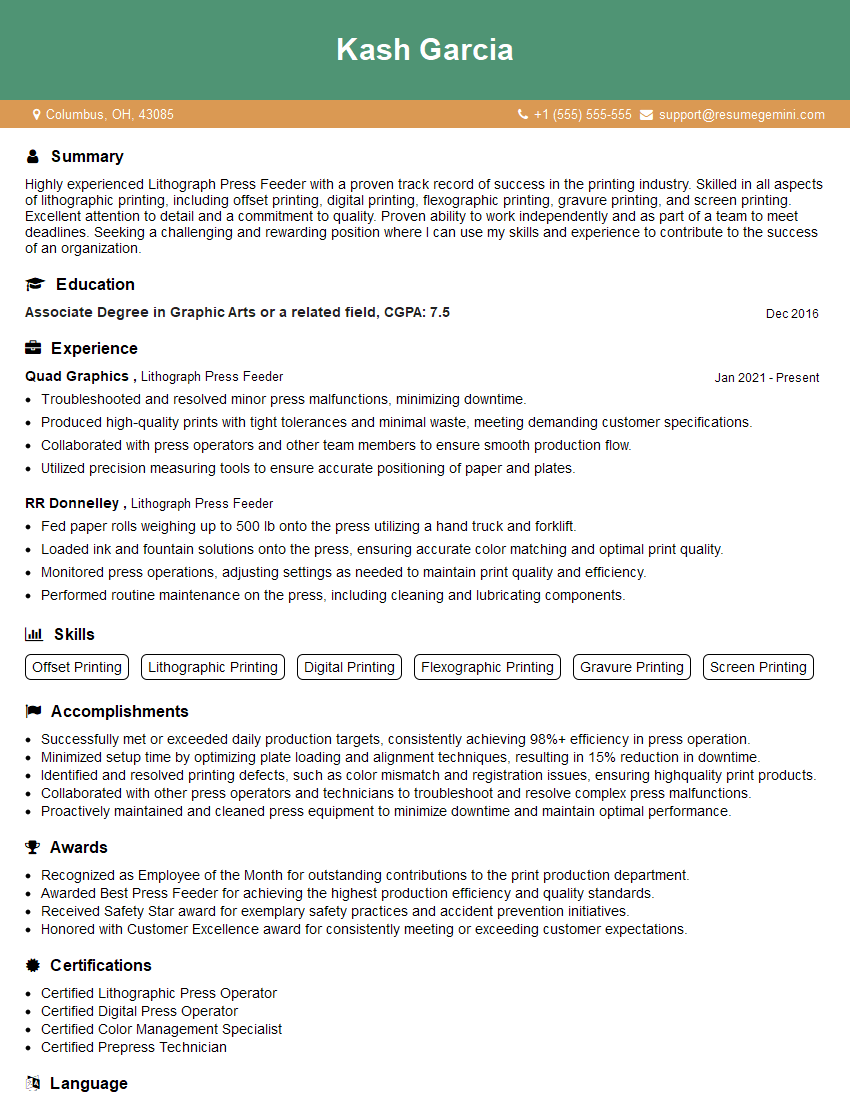

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lithograph Press Feeder

1. What are the main tasks and responsibilities of a Lithograph Press Feeder?

As a Lithograph Press Feeder, my primary responsibilities involve:

- Loading paper sheets into the feeder of a lithographic printing press

- Monitoring the paper feeding process and ensuring smooth operation

- Adjusting press settings to optimize paper flow and print quality

- Inspecting printed sheets for defects and reporting any issues

- Maintaining and cleaning the press and feeder

- Following established safety regulations and procedures

- Working with other press operators and supervisors as needed

2. Describe the different types of paper commonly used in lithographic printing and their key characteristics.

Lithographic printing typically uses various types of paper, each with distinct characteristics:

Offset Paper:

- Uncoated paper with a smooth surface

- Good absorption and ink receptivity

- Ideal for high-volume printing and general applications

Coated Paper:

- Paper with a coated surface that enhances print quality

- Provides a glossy or matte finish

- Suitable for high-quality prints, magazines, and brochures

Specialty Papers:

- Papers with unique textures, colors, or finishes

- Used for special effects and artistic purposes

3. Explain the importance of proper paper handling in lithographic printing.

Proper paper handling is crucial in lithographic printing for several reasons:

- Prevent paper jams and damage: Improper handling can cause paper to fold, wrinkle, or tear, leading to jams and downtime.

- Maintain print quality: Smooth and flat paper ensures consistent ink transfer and high-quality prints.

- Reduce waste and costs: Avoiding paper spoilage and press downtime saves time and resources.

- Enhance press life: Gentle paper handling minimizes wear and tear on the press and extends its lifespan.

4. How do you calibrate and adjust a lithographic press to ensure optimal print quality?

Calibrating and adjusting a lithographic press involves the following steps:

- Feeder calibration: Setting the paper feeding mechanism to ensure proper sheet alignment and spacing.

- Impression and blanket settings: Adjusting the pressure and position of the impression cylinder and blanket to achieve the desired print density and sharpness.

- Ink and water balance: Adjusting the ink and water rollers to maintain the correct balance for optimal ink transfer and print quality.

- Registration: Ensuring that the printed image is aligned correctly on the paper.

- Color matching: Adjusting the ink formulations and press settings to achieve accurate color reproduction.

5. Describe the safety precautions you should observe when operating a lithographic press.

When operating a lithographic press, it is crucial to follow safety precautions to prevent accidents and injuries:

- Wear appropriate safety gear: Including gloves, eye protection, and closed-toe shoes.

- Be aware of moving parts: Keep hands, hair, and clothing away from rotating rollers and gears.

- Use caution when handling heavy paper rolls: Use proper lifting techniques and avoid overexertion.

- Maintain a clean and organized work area: Remove paper scraps and debris to prevent slipping or tripping hazards.

- Be aware of chemical hazards: Follow instructions for handling inks, solvents, and cleaning agents.

- Report any issues immediately: Notify supervisors or maintenance personnel of any unusual noises, vibrations, or equipment malfunctions.

6. How do you troubleshoot common problems encountered while operating a lithographic press?

Common troubleshooting techniques for lithographic press problems include:

- Paper jams: Check paper alignment, adjust feeder settings, and clear any obstructions.

- Print quality issues: Inspect print quality for streaks, smudges, or poor color reproduction. Adjust press settings, check ink and water levels, and clean printing plates.

- Registration problems: Ensure paper is properly aligned, adjust press settings, and check for worn rollers.

- Mechanical issues: Check for loose belts, worn gears, or other mechanical problems that may affect press operation.

- Electrical problems: Check for loose connections, tripped breakers, or faulty electrical components.

7. How do you maintain and clean a lithographic press to ensure its longevity?

Proper maintenance and cleaning of a lithographic press are essential for its longevity:

- Regular cleaning: Remove ink, paper dust, and debris from the press, rollers, and printing plates using approved cleaning agents.

- Lubrication: Apply lubricants to moving parts according to the manufacturer’s instructions to reduce friction and wear.

- Roller maintenance: Clean and condition rollers to ensure proper ink transfer and print quality.

- Periodic inspections: Check the press for worn or damaged parts and perform necessary repairs or replacements.

- Preventative maintenance: Follow a scheduled maintenance plan to identify and address potential issues before they become major problems.

8. What are the key qualities and skills required to be an effective Lithograph Press Feeder?

To be an effective Lithograph Press Feeder, the following qualities and skills are essential:

- Attention to detail: Ensuring accuracy and consistency in paper handling and press operation.

- Mechanical aptitude: Understanding the press’s mechanics and performing basic maintenance tasks.

- Problem-solving skills: Identifying and resolving issues that may arise during press operation.

- Physical stamina: Ability to stand for extended periods and handle heavy paper rolls.

- Teamwork and communication: Working effectively with other press operators and supervisors.

- Safety consciousness: Adhering to established safety regulations and procedures.

9. How do you stay updated with the latest advancements in lithographic printing technology?

To stay up-to-date with advancements in lithographic printing technology, I pursue the following approaches:

- Attend industry events and webinars: Participating in conferences and online seminars to learn about new technologies and trends.

- Read industry publications: Subscribing to trade magazines and online resources to stay informed about developments in the field.

- Connect with peers and experts: Networking with other press operators and industry professionals to exchange knowledge and ideas.

- Engage in continuous learning: Seeking opportunities for additional training and certifications to enhance my skills and knowledge.

10. Describe your experience with different sizes and types of lithographic presses.

Throughout my career, I have worked with various sizes and types of lithographic presses, including:

- Sheet-fed presses: Used for printing on individual sheets of paper, ranging from small to large formats.

- Web presses: Used for high-volume printing on continuous rolls of paper, typically for newspapers and magazines.

- Offset presses: A type of sheet-fed press that transfers the ink image to an intermediate roller before it is transferred to the paper, providing high-quality prints.

- Digital presses: Utilize digital technology to directly print images from a computer file to paper, offering flexibility and short turnaround times.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lithograph Press Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lithograph Press Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lithograph Press Feeders play a crucial role in the printing process, ensuring the smooth flow of paper through the press. Their key responsibilities include:

1. Assisting Press Operators

Feeders assist press operators by loading paper into the press feeder, adjusting paper flow, and monitoring the printing process.

- Loading and unloading paper rolls onto the press

- Adjusting paper tension and alignment to ensure proper printing

2. Maintaining the Press and Equipment

Feeders are responsible for maintaining the press and related equipment to ensure optimal performance.

- Cleaning and lubricating the press and feeder

- Inspecting and replacing worn or damaged parts

3. Monitoring the Printing Process

Feeders monitor the printing process and identify any potential issues that may affect the quality of the product.

- Checking for ink levels and correcting as needed

- Monitoring paper flow to prevent jams or misfeeds

4. Troubleshooting and Problem-Solving

Feeders are expected to troubleshoot and resolve minor issues that may arise during the printing process.

- Identifying and resolving paper jams and other printing errors

- Communicating with press operators to diagnose and resolve complex issues

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips and hacks to help you ace your Lithograph Press Feeder interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, products or services, and the specific requirements of the Lithograph Press Feeder position. This will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages

- Read industry publications and articles

2. Practice Common Interview Questions

Anticipate and prepare for common interview questions related to your skills, experience, and motivation. Practice answering these questions out loud to improve your articulation and confidence.

- Tell me about your experience working in a printing environment

- Describe a time when you had to troubleshoot a complex printing issue

3. Showcase Your Technical Aptitude

Emphasize your technical knowledge and skills relevant to the role. Explain your understanding of printing processes, press equipment, and troubleshooting techniques.

- Describe your experience in loading and unloading paper rolls

- Explain how you would handle a paper jam

4. Highlight Your Attention to Detail and Quality

Stress your meticulous nature and commitment to delivering high-quality work. Provide examples of how you have ensured accuracy and precision in previous roles.

- Discuss your experience in maintaining equipment and ensuring proper paper alignment

- Explain how you monitor the printing process to identify any potential issues

5. Demonstrate Your Team Player Abilities

Emphasize your ability to work effectively in a team environment. Explain how you collaborate with others and contribute to a positive work atmosphere.

- Describe your experience in assisting press operators and resolving issues

- Explain how you communicate with colleagues to ensure smooth workflow

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lithograph Press Feeder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!