Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lithoplate Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

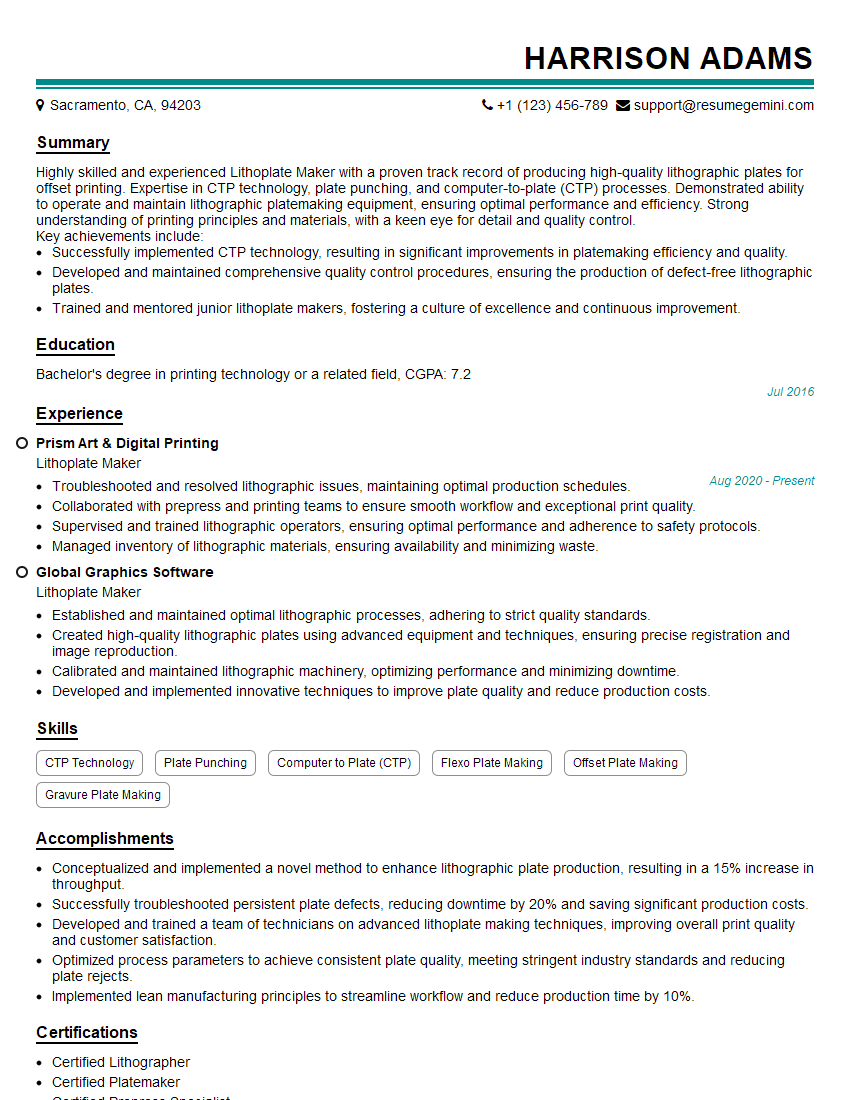

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lithoplate Maker

1. What is the role of a lithoplate maker, and what are the essential responsibilities?

The lithoplate maker is primarily responsible for creating lithographic plates used in offset printing. The crucial responsibilities include:

- Translating digital or physical artwork into printing plates.

- Preparing and processing photographic negatives or positives.

- Operating lithographic plate-making equipment.

- Maintaining and calibrating plate-making machinery.

- Ensuring the accuracy and quality of lithographic plates.

2. Describe the process of making a lithoplate.

The lithoplate making process typically involves the following steps:

Preparing the artwork

- The digital artwork is received and prepared for plate making.

- The artwork is checked for errors, and any necessary adjustments are made.

- The artwork is then output to a film or digital plate.

Creating the lithographic plate

- A photosensitive lithographic plate is coated with a light-sensitive emulsion.

- The film or digital plate is placed on top of the lithographic plate.

- The plate is exposed to ultraviolet light, which hardens the emulsion in the areas that were exposed to light.

- The unexposed emulsion is then washed away, leaving behind a hardened image on the lithographic plate.

Finishing the lithographic plate

- The hardened image on the lithographic plate is baked to further harden the emulsion.

- The plate is then gummed to make it water-resistant.

- The plate is inspected for defects and is ready for use in the printing press.

3. What factors affect the quality of a lithoplate?

The quality of a lithoplate is influenced by several factors, including:

- The quality of the artwork.

- The accuracy of the plate-making process.

- The condition of the lithographic plate-making equipment.

- The skill and experience of the lithoplate maker,

- The environmental conditions in which the plate is made.

4. What are the different types of lithographic plates?

There are several types of lithographic plates, including:

- Presensitized plates: These plates are coated with a light-sensitive emulsion and are ready to use immediately.

- Non-presensitized plates: These plates require a separate coating of light-sensitive emulsion before they can be used.

- Digital plates: These plates are created using a computer-to-plate (CTP) system and do not require the use of film.

- Metal plates: These plates are made of metal and are more durable than paper plates.

- Paper plates: These plates are made of paper and are less durable than metal plates.

5. What are the advantages and disadvantages of using digital plates?

Digital plates offer several advantages over traditional film-based plates, including:

- Faster plate-making times.

- Higher quality images.

- Reduced waste.

- Fewer press stops.

However, digital plates also have some disadvantages, including:

- Higher equipment costs.

- More complex plate-making process.

- Greater need for skilled operators.

6. What are the common problems that can occur during the lithoplate making process?

Several problems can occur during the lithoplate making process, including:

- Incorrect exposure of the plate.

- Improper development of the plate.

- Damage to the plate during handling.

- Contamination of the plate.

- Equipment malfunctions.

7. How do you troubleshoot problems that occur during the lithoplate making process?

Troubleshooting problems that occur during the lithoplate making process involves the following steps:

- Identifying the problem.

- Determining the cause of the problem.

- Taking corrective action.

- Verifying that the problem has been resolved.

8. What are the safety precautions that should be taken when working with lithographic plates?

When working with lithographic plates, it is important to take several safety precautions, including:

- Wearing gloves and eye protection.

- Using proper ventilation.

- Avoiding skin contact with chemicals.

- Storing plates in a safe and dry place.

- Following all manufacturer’s instructions.

9. What are the latest trends in lithographic plate making?

The latest trends in lithographic plate making include:

- The use of digital plates.

- The development of new plate materials.

- The use of automation in the plate-making process.

10. What are your strengths and weaknesses as a lithoplate maker?

As a lithoplate maker, my strengths include:

- My attention to detail.

- My ability to troubleshoot problems.

- My commitment to quality.

My weaknesses include:

- My lack of experience with digital plates.

- My tendency to be perfectionistic.

However, I am eager to learn new skills and improve my weaknesses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lithoplate Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lithoplate Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A lithoplate maker, also known as a lithographic platemaker, is a crucial member of the lithographic printing process. They are responsible for creating lithographic plates, which are used to transfer images onto paper during printing. The following are some key job responsibilities of a lithoplate maker:

1. Preparation of Lithographic Plates

Preparing lithographic plates involves cleaning, sensitizing, and coating the plates with a light-sensitive emulsion. The platemaker ensures that the plates are adequately prepared to receive the image.

2. Exposure and Development of Plates

Lithoplate makers expose the prepared plates to light through a negative or digital file. This creates a latent image on the plate, which is then developed using chemical solutions. The resulting image on the plate is a mirror image of the original.

3. Etching of Plates

After development, the platemaker etches the plate using acids or other etching solutions. This process removes non-image areas, leaving a raised image on the plate.

4. Finishing and Quality Control

Once the etching process is complete, the platemaker finishes the plate by removing any remaining light-sensitive emulsion and performing quality checks to ensure the plate meets specifications.

5. Troubleshooting and Maintenance

Lithoplate makers are responsible for troubleshooting and maintaining platemaking equipment to ensure optimal performance and prevent downtime.

Interview Tips

Preparing thoroughly for a lithoplate maker interview can significantly increase your chances of success. Here are some interview tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the company you are applying to and the lithographic printing industry. This will help you understand the company’s culture, products, and current trends in the field.

2. Practice Answering Common Interview Questions

Prepare for common interview questions such as, “Tell me about your experience in lithographic platemaking” and “What are the key challenges in platemaking?” Practice your answers to these questions, ensuring you highlight your skills and experience.

3. Showcase Your Technical Skills

Lithoplate making requires technical proficiency. Emphasize your knowledge of plate preparation, exposure, etching, and finishing techniques during the interview. You can also mention any specialized software or equipment you are familiar with.

4. Highlight Your Precision and Attention to Detail

Lithoplate making requires precision and attention to detail. During the interview, provide examples of your ability to follow instructions accurately, maintain a clean and organized work environment, and produce high-quality plates.

5. Be Enthusiastic and Passionate

Show the interviewer that you are genuinely interested in lithographic platemaking and the printing industry. Express your enthusiasm for the role and your desire to contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lithoplate Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!