Are you gearing up for a career in Machine Silk Screen Printer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Machine Silk Screen Printer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

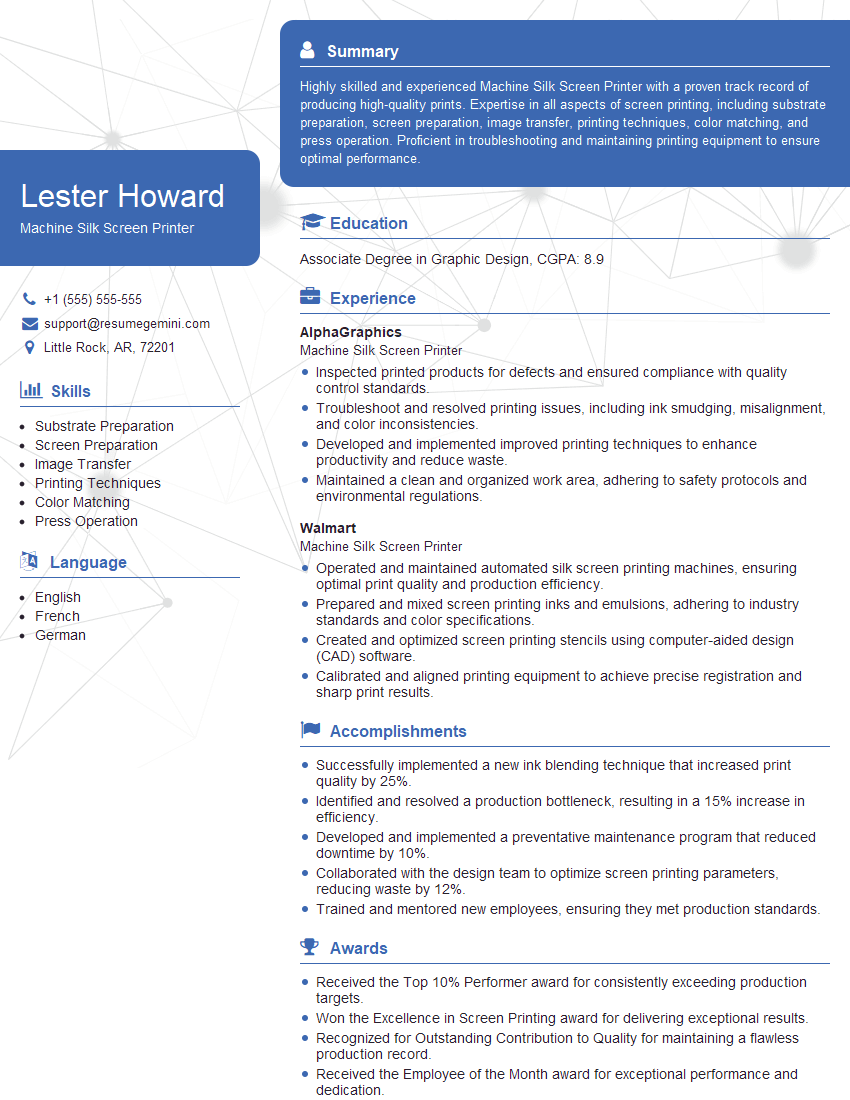

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Silk Screen Printer

1. Describe the process of preparing a silk screen for printing.

- Degreasing the screen to remove any dirt or oils.

- Applying a photosensitive emulsion to the screen and exposing it to light through a positive film.

- Developing the emulsion to create a stencil of the desired image.

- Drying and hardening the stencil.

2. What factors affect the quality of a silk screen print?

Substrate

- Material (e.g., paper, fabric, plastic)

- Surface texture

- Absorption rate

Ink

- Viscosity

- Color

- Transparency

Screen Mesh

- Count (threads per inch)

- Material (e.g., nylon, polyester)

- Tension

Printing Technique

- Squeegee pressure

- Printing speed

- Number of passes

3. How do you troubleshoot common silk screen printing problems, such as ghosting, pinholes, and ink streaking?

- Ghosting: caused by ink bleeding through the stencil. Can be resolved by increasing exposure time, using a higher mesh count screen, or adjusting squeegee pressure.

- Pinholes: caused by small holes in the stencil. Can be resolved by inspecting the screen for damage or using a higher mesh count screen.

- Ink streaking: caused by ink flowing under the stencil. Can be resolved by adjusting squeegee pressure, increasing ink viscosity, or using a higher mesh count screen.

4. What is the difference between wet-on-wet and wet-on-dry printing?

- Wet-on-wet: printing multiple layers of ink while the previous layer is still wet. This allows for blending and creating special effects.

- Wet-on-dry: printing multiple layers of ink after the previous layer has dried. This provides better control over color and registration.

5. How do you maintain and store silk screens to ensure their longevity?

- Cleaning screens immediately after use with water or solvent.

- Storing screens in a cool, dry place away from direct sunlight.

- Inspecting screens regularly for damage and repairing any holes or tears.

6. What safety precautions should be taken when working with silk screen printing equipment and materials?

- Wearing appropriate safety gear (e.g., gloves, apron, respirator).

- Ensuring proper ventilation in the printing area.

- Storing chemicals and solvents safely and disposing of them properly.

7. How do you ensure accurate registration when printing multiple colors on a single item?

- Using registration marks on the screen and substrate.

- Inspecting the registration regularly throughout the printing process.

- Adjusting the printing press or screen position as needed.

8. What is the best way to mix and prepare ink for silk screen printing?

- Following the manufacturer’s instructions for mixing ratios and curing times.

- Using a scale to ensure accurate measurements.

- Thoroughly mixing the ink with a stir stick or spatula.

9. How do you handle special printing techniques, such as metallic inks or discharge printing?

In addition to the standard silk screen printing process, I have experience with specialized printing techniques such as metallic inks and discharge printing. For metallic inks, I ensure that the substrate is properly prepared and use a high-quality adhesive to prevent the ink from flaking. For discharge printing, I carefully control the printing temperature and time to achieve the desired effect without damaging the fabric.

10. What are the latest trends and innovations in silk screen printing?

I keep myself updated with the latest trends and innovations in silk screen printing. Some emerging trends include the use of digital printing techniques to create high-quality, full-color prints, and the development of new inks and materials that allow for printing on a wider range of substrates. I am eager to explore these new technologies and incorporate them into my work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Silk Screen Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Silk Screen Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Silk Screen Printers are entrusted with the responsibility of operating and maintaining state-of-the-art silk screen printing equipment. Their primary focus is to produce high-quality printed materials, ensuring that they meet the specified requirements and standards.

1. Silk Screen Printing Operations

They are adept at setting up and operating silk screen printing machines, expertly handling various substrates and ensuring optimal printing conditions.

- Capable of adjusting machine settings, including speed, pressure, and temperature, to achieve desired print results.

- Proficient in loading and unloading substrates, such as textiles, paper, and plastics, ensuring proper alignment and registration.

2. Quality Control and Inspection

Maintaining impeccable quality standards is paramount. They meticulously inspect printed materials, verifying their accuracy, clarity, and overall appearance.

- Thoroughly examining prints for defects, including smudges, misprints, and color inconsistencies, ensuring that only flawless products are released.

- Collaborating with quality control teams to identify and address any potential issues, implementing corrective actions to maintain high standards.

3. Machine Maintenance and Troubleshooting

To ensure uninterrupted operations, they are responsible for maintaining and troubleshooting silk screen printing machines.

- Conducting regular inspections, cleaning, and lubrication of equipment, minimizing downtime and maximizing productivity.

- Skilled in diagnosing and resolving technical issues, ensuring swift resolution and minimizing disruptions to production schedules.

4. Health and Safety Compliance

Adhering to established health and safety protocols is non-negotiable. They prioritize the well-being of themselves and others.

- Maintaining a clean and organized work area, ensuring a safe and efficient work environment.

- Complying with all applicable safety regulations, including proper handling and storage of chemicals and hazardous materials.

Interview Tips

Preparing for an interview can be daunting, but with the right approach, you can increase your chances of success. Here are some key tips to help you stand out:

1. Research the Company and Position

Demonstrate your interest and enthusiasm by thoroughly researching the company’s background, industry, and specific job requirements. This knowledge will enable you to tailor your responses and show that you have a genuine understanding of the role.

- Visit the company’s website, read industry articles, and check social media platforms to gather information.

- Carefully review the job description, noting the key responsibilities and qualifications to highlight your relevant skills and experience.

2. Practice Your Answers

Preparation is key. Take the time to anticipate potential interview questions and formulate well-structured responses. Practice delivering your answers out loud, ensuring clarity and conciseness.

- Consider using the STAR method (Situation, Task, Action, Result) to provide specific examples of your skills and accomplishments.

- Seek feedback from a friend, family member, or career counselor to refine your answers and presentation style.

3. Highlight Your Technical Skills

Emphasize your proficiency in silk screen printing techniques and equipment. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your capabilities.

- Describe your experience in operating different types of silk screen printing machines and the range of substrates you have handled.

- Provide examples of how you have optimized printing processes, reduced defects, or improved production efficiency.

4. Showcase Your Attention to Detail

Quality control is crucial in silk screen printing. Highlight your keen eye for detail and ability to identify and correct errors.

- Explain your inspection procedures and the steps you take to ensure the accuracy and consistency of printed materials.

- Share instances where you have identified and resolved quality issues, preventing defective products from reaching customers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Silk Screen Printer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!