Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mandrel Press Hand position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

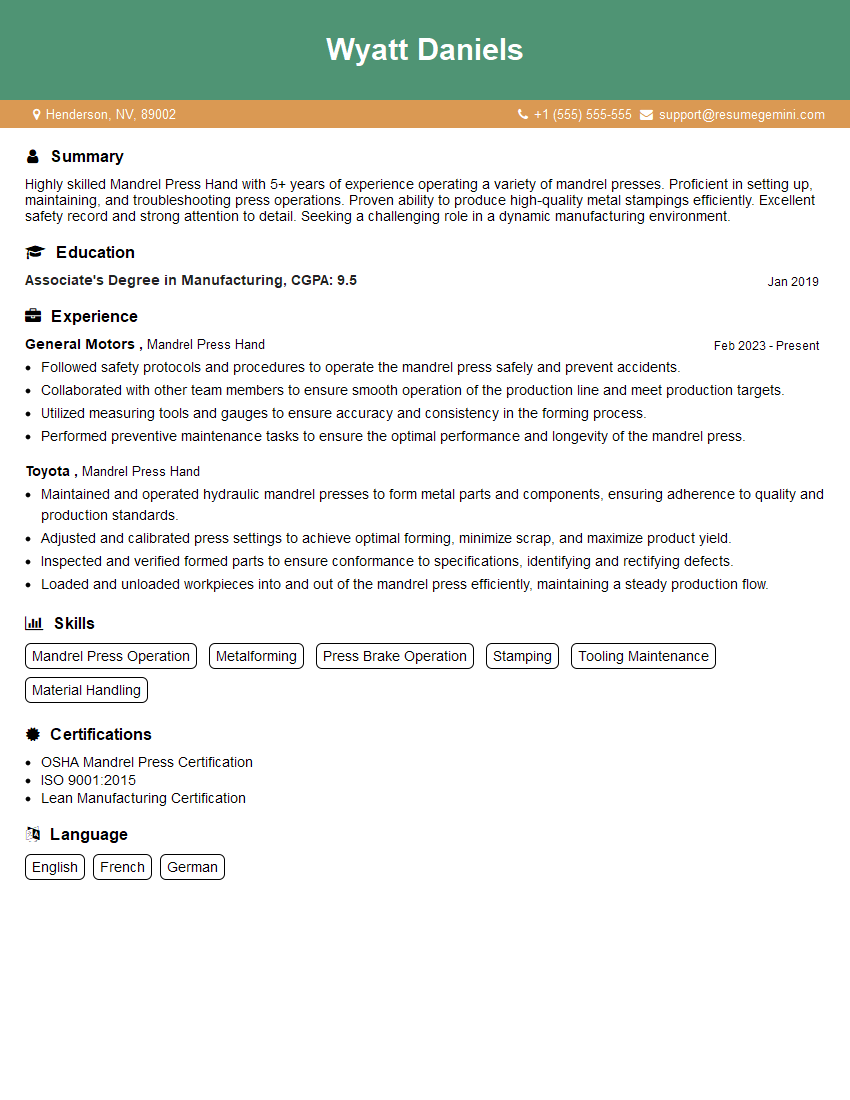

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mandrel Press Hand

1. Describe the process of operating a mandrel press machine?

- Position the material on the mandrel.

- Secure the material with a clamping device.

- Set the machine’s pressure and speed settings.

- Engage the machine’s press ram to bend the material.

- Release the material from the clamping device.

2. What are the different types of bends that can be created using a mandrel press machine?

Types of Bends

- V-bends

- U-bends

- Channel bends

- Hem bends

Factors Affecting Bend Type

- Material thickness

- Material properties

- Mandrel size and shape

- Press machine settings

3. What are the safety precautions that should be observed when operating a mandrel press machine?

- Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Inspect the machine before each use to ensure that it is in good working condition.

- Keep the work area clean and free of debris.

- Never operate the machine under the influence of alcohol or drugs.

- Follow all manufacturer’s instructions for safe operation.

4. How do you determine the correct mandrel size for a given bend?

- Consider the material thickness.

- Determine the desired bend radius.

- Refer to the manufacturer’s mandrel size chart.

- Select the mandrel size that corresponds to the material thickness and desired bend radius.

5. What are the common problems that can occur when operating a mandrel press machine, and how can they be resolved?

- Material cracking: Use a larger mandrel size or reduce the bending force.

- Material slipping: Increase the clamping force or use a non-slip material.

- Machine malfunction: Stop the machine and consult the manufacturer’s instructions.

6. How do you maintain a mandrel press machine to ensure optimal performance?

- Regularly clean and lubricate the machine.

- Inspect the mandrels and dies for wear and damage.

- Calibrate the machine according to the manufacturer’s instructions.

- Follow a preventative maintenance schedule.

7. Describe the different materials that can be bent using a mandrel press machine.

- Steel

- Aluminum

- Copper

- Brass

- Plastic

8. What are the advantages of using a mandrel press machine compared to other bending methods?

- Precise bends

- Consistent results

- High production rates

- Suitable for a wide range of materials

9. How do you troubleshoot a mandrel press machine that is not producing the desired bends?

- Check the mandrel size and shape.

- Inspect the material for defects.

- Adjust the machine’s pressure and speed settings.

- Calibrate the machine.

10. What are the different types of mandrel press machines available?

- Manual mandrel press machines

- Hydraulic mandrel press machines

- Pneumatic mandrel press machines

- CNC mandrel press machines

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mandrel Press Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mandrel Press Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Mandrel Press Hand is a manufacturing professional who operates a mandrel press, a machine used in the production of various precision-engineered components.

1. Mandrel Press Operation

The primary task of a Mandrel Press Hand is to operate the mandrel press efficiently and safely. They are responsible for setting up, adjusting, and maintaining the machine to ensure smooth and effective operation.

- Setting up and adjusting the mandrel press for different production runs.

- Loading and unloading the mandrel press with raw materials and finished products.

- Monitoring the mandrel press during operation and making adjustments as needed.

- Identifying and troubleshooting any operational issues or malfunctions.

2. Quality Control and Inspection

Mandrel Press Hands are also responsible for ensuring the quality of the components produced. They perform inspections and checks to ensure that the components meet the required specifications and tolerances.

- Inspecting components for defects, dimensional accuracy, and surface finish.

- Conducting quality checks and measurements using gauges, calipers, and other tools.

- Reporting any quality issues or defects to the supervisor.

- Maintaining records of quality checks and inspections.

3. Maintenance and Cleaning

To ensure the longevity and optimal performance of the mandrel press, the Mandrel Press Hand is responsible for routine maintenance and cleaning tasks.

- Cleaning and lubricating the mandrel press as per maintenance schedules.

- Replacing worn or damaged parts and components.

- Conducting regular inspections for potential issues or wear and tear.

- Following established safety protocols and procedures.

4. Safety

Mandrel press operation involves potential hazards, so the Mandrel Press Hand must prioritize workplace safety.

- Adhering to all safety guidelines and regulations.

- Wearing appropriate personal protective equipment (PPE).

- Maintaining a clean and organized work area.

- Reporting any safety concerns or incidents immediately.

Interview Tips

Preparing well for an interview can significantly increase your chances of success. Here are some tips to help you ace your Mandrel Press Hand interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, mission, values, and products or services. Understand the specific requirements and responsibilities of the Mandrel Press Hand position.

- Visit the company’s website and LinkedIn page.

- Read industry news and articles.

- Identify the main keywords in the job description and tailor your resume and answers accordingly.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in operating mandrel presses, quality control, and maintenance. Use specific examples and quantifiable results to demonstrate your abilities.

- Provide details on the types of mandrel presses you have operated and the components you have produced.

- Describe your experience in implementing quality control measures and conducting inspections.

- Highlight your knowledge of maintenance procedures and your ability to troubleshoot and resolve issues.

3. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that showcase your skills and qualifications. Practice your answers aloud to improve your delivery and confidence.

- Introduce yourself and your background.

- Describe your experience with mandrel press operation and quality control.

- Explain your approach to troubleshooting and problem-solving.

- Discuss your safety practices and awareness.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare a few questions that show your eagerness to learn more about the company and the role.

- What is the company’s vision for the future?

- What are the major challenges and opportunities facing the industry?

- What are the expectations for the Mandrel Press Hand in the first 90 days?

- What professional development opportunities are available?

5. Follow Up

After the interview, send a thank-you note to the interviewer within 24 hours. Reiterate your interest in the position and thank them for their time. You can also use this opportunity to address any points you may have missed during the interview.

- Reiterate your key skills and experiences.

- Express your enthusiasm for the opportunity.

- Inquire about the next steps in the hiring process.

Next Step:

Now that you’re armed with the knowledge of Mandrel Press Hand interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mandrel Press Hand positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini