Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Marking Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

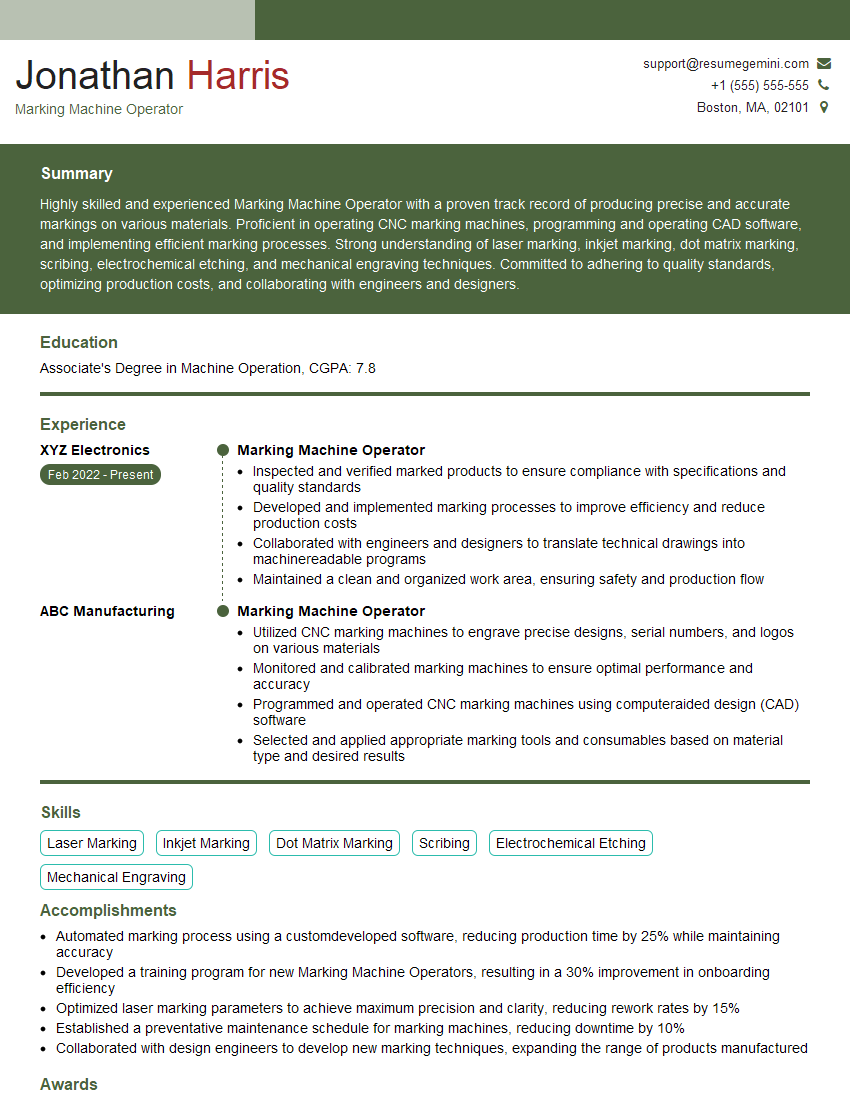

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Marking Machine Operator

1. Describe the process of setting up a marking machine for a new product.

To set up a marking machine for a new product, I would first consult with the engineering team to determine the marking requirements. I would then select the appropriate marking method, such as laser, ink jet, or dot peen. Next, I would install the necessary fixtures and tooling to hold the product in place and orient it for marking. Finally, I would create a new program or modify an existing program to control the marking machine and ensure the product is marked correctly.

2. How do you maintain marking quality over long production runs and adjust for variables such as material, product, or environmental changes?

Quality Control

- Adhere to established quality standards.

- Regularly inspect and calibrate equipment.

- Use high-quality materials and supplies.

Variable Adjustments

- Calibrate settings based on material properties.

- Select suitable marking methods for specific materials.

- Compensate for environmental fluctuations (e.g., temperature, humidity).

3. Explain the different marking techniques used in manufacturing and their applications.

- Laser Marking: Precise and permanent markings on various materials (e.g., metal, plastic, glass).

- Inkjet Marking: Non-contact marking using liquid ink for fast, high-volume applications (e.g., packaging, food).

- Dot Peen Marking: Durable markings created by hammering a stylus into the surface (e.g., metal parts, tools).

- Thermal Transfer Printing: Printing images and text using heated ribbons (e.g., labels, tags).

- Electrochemical Etching: Creating permanent marks on metal surfaces using an electrochemical process.

4. How do you troubleshoot common marking problems, such as smudging, fading, or misalignment?

- Smudging: Check ink viscosity, nozzle alignment, and drying time.

- Fading: Ensure proper ink selection, curing methods, and substrate compatibility.

- Misalignment: Inspect fixtures, sensors, and programming for accuracy.

- Other: Consider factors such as laser power, marking speed, and material characteristics.

5. What safety precautions should be taken when operating a marking machine?

- Wear appropriate personal protective equipment (PPE).

- Keep hands and body parts away from moving machinery.

- Follow manufacturer’s instructions for machine operation.

- Handle hazardous materials with caution (e.g., inks, solvents).

- Maintain a clean and organized work area.

6. How do you ensure the accuracy and consistency of marking results?

- Properly calibrate and maintain equipment.

- Use precise fixtures and tooling for product positioning.

- Establish and follow standardized marking procedures.

- Implement quality control measures (e.g., inspections, sample checks).

- Continuously monitor and adjust settings as needed.

7. Explain the importance of using high-quality marking supplies and how they impact marking outcomes.

- Ink quality: Affects adhesion, durability, and color fastness.

- Laser consumables: Influence beam quality and marking precision.

- Marking substrates: Determine compatibility, etching depth, and overall mark quality.

- High-quality supplies ensure: Consistent results, reduced downtime, improved product appearance.

8. How do you stay updated with the latest advancements in marking technology?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Engage with industry professionals and vendors.

- Participate in training and certification programs.

- Research and experiment with new marking techniques.

9. How do you prioritize tasks and manage time effectively in a fast-paced manufacturing environment?

- Establish clear priorities based on deadlines and production schedules.

- Break down tasks into smaller, manageable steps.

- Utilize time management techniques (e.g., to-do lists, calendars).

- Delegate tasks to team members when possible.

- Stay organized and keep a clean workspace.

10. What is your approach to continuous improvement and how do you incorporate it into your daily work?

- Regularly evaluate current processes and identify areas for improvement.

- Seek feedback from colleagues, customers, and management.

- Experiment with new ideas and technologies to optimize marking operations.

- Document and share best practices to enhance overall team performance.

- Stay informed about industry advancements and incorporate them into daily work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Marking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Marking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Marking Machine Operators are responsible for operating machines that mark, engrave, or otherwise identify products and materials. They must be able to operate a variety of machines, set up and calibrate the equipment, and maintain a clean and organized work area.

1. Machine Operation

Operate marking machines to mark or engrave products with identifying information, such as product numbers, logos, and other designs.

- Select and install the correct marking tools and materials for the job.

- Adjust machine settings, such as pressure, speed, and temperature.

- Ensure that the marking is accurate and meets customer specifications.

2. Quality Control

Inspect marked products to ensure that they meet quality standards.

- Identify and correct any defects in the marking process.

- Maintain records of inspection results.

3. Machine Maintenance

Clean and maintain marking machines to ensure optimal performance.

- Clean and lubricate machine parts as needed.

- Calibrate the machine to ensure accuracy.

- Troubleshoot and resolve machine problems.

4. Safety Procedures

Follow all safety procedures to protect themselves and others.

- Wear appropriate personal protective equipment, such as safety glasses and gloves.

- Operate machines in a safe manner.

- Report any accidents or injuries to the supervisor.

Interview Tips

Preparing for an interview for a Marking Machine Operator position can be overwhelming. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific skills and experience they are looking for in a Marking Machine Operator.

- Visit the company’s website and social media pages.

- Read articles and news about the company.

- Talk to your network to see if anyone knows anything about the company or the position.

2. Practice Your Answers

Once you have a good understanding of the company and the position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Write down a list of potential questions.

- Practice answering the questions out loud.

- Get feedback from a friend or family member.

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for an office setting.

- Avoid wearing revealing or casual clothing.

- Choose clothes that are comfortable and allow you to move freely.

- Make sure your clothes are clean and free of wrinkles.

4. Be Enthusiastic and Positive

The interviewer wants to see that you are enthusiastic about the position and the company. Be positive and upbeat during the interview, and show that you are genuinely interested in the opportunity.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Ask questions about the company and the position.

Next Step:

Now that you’re armed with the knowledge of Marking Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Marking Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini