Are you gearing up for an interview for a Offset Lithographic Press Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Offset Lithographic Press Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

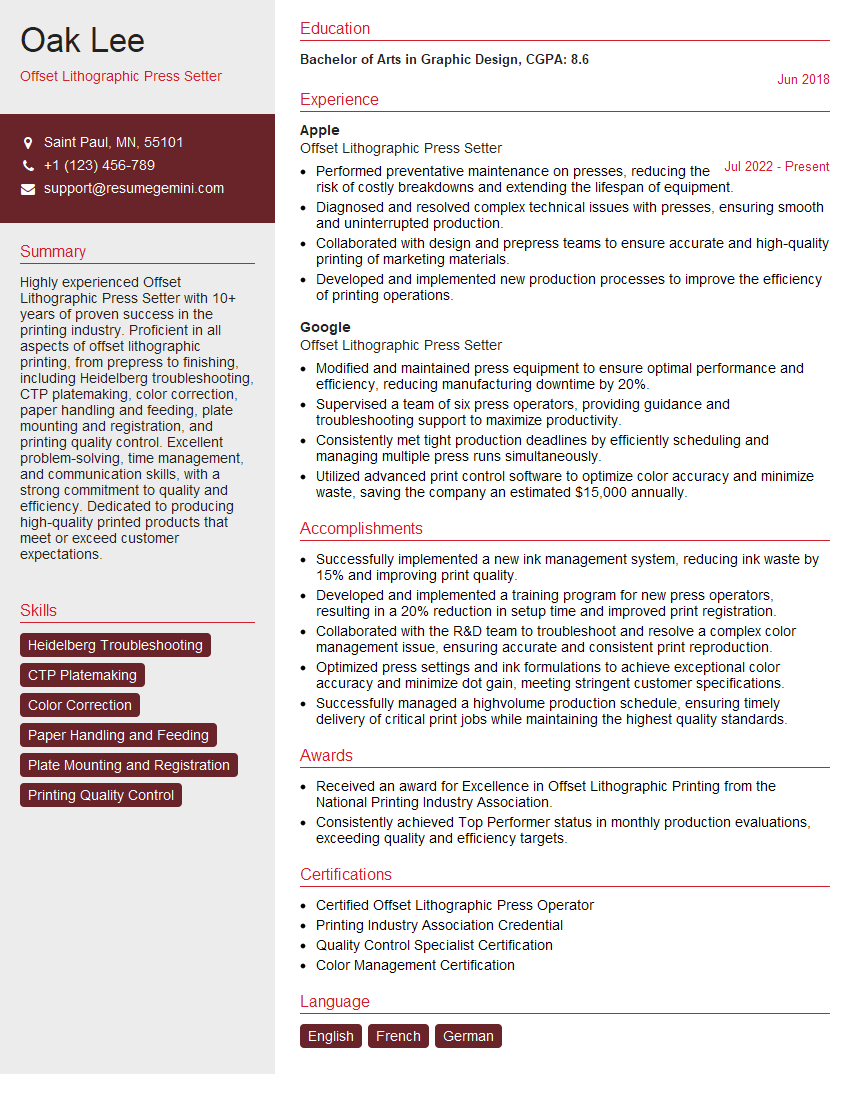

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Offset Lithographic Press Setter

1. What are the key steps involved in the offset lithographic printing process?

- Prepress: Preparing the digital files, creating plates, and proofs.

- Press: Setting up the press, loading plates, adjusting ink and water balance, and printing.

- Postpress: Finishing operations such as cutting, folding, binding, and packaging.

2. Describe the role of ink and water in the offset lithographic printing process.

- Ink: Transfers the image from the plate to the paper or other substrate.

- Water: Keeps non-image areas of the plate free from ink.

3. How do you adjust the ink and water balance on an offset lithographic press?

- Ink: Adjust the ink keys to increase or decrease ink flow.

- Water: Adjust the water fountain to increase or decrease water flow.

4. What are some common troubleshooting issues in offset lithographic printing?

Paper feeding issues, ink smudging, ghosting, color registration problems, and drying problems.

5. How do you ensure that printed products meet quality standards?

- Regular press checks and color matching.

- Using calibrated equipment and materials.

- Implementing quality control procedures.

6. What are the different types of offset lithographic printing presses?

- Sheetfed presses: Print on individual sheets of paper.

- Web presses: Print on a continuous roll of paper.

- Heatset presses: Use heat to dry the ink quickly.

7. What are the advantages of using an offset lithographic printing process?

- High quality, consistent printing.

- Wide range of substrates and ink options.

- Cost-effective for large print runs.

8. What are the different types of plates used in offset lithographic printing?

- Presensitized plates: Pre-coated with a photosensitive emulsion.

- Thermal plates: Images are created using a laser or thermal process.

- Computer-to-plate (CTP) systems: Plates are created directly from digital files.

9. How do you maintain an offset lithographic printing press?

- Regular cleaning and lubrication.

- Replacing worn or damaged parts.

- Calibrating equipment.

10. What are some advancements in offset lithographic printing technology?

- Digital imaging and platemaking.

- Automated press controls.

- In-line finishing and inspection systems.

11. How do you work effectively in a team environment?

- Communicating clearly and sharing information.

- Supporting colleagues and assisting with tasks.

- Respecting different perspectives and working towards common goals.

12. What do you do to stay up-to-date on industry best practices?

- Attending workshops and conferences.

- Reading industry publications and online resources.

- Networking with other printers and professionals.

13. How would you handle a situation where a customer is dissatisfied with the print quality?

- Listen attentively to the customer’s concerns.

- Inspect the printed product and identify any issues.

- Offer solutions and work towards a resolution that satisfies the customer.

14. What is your understanding of color management in offset lithographic printing?

- Matching colors accurately across different devices and substrates.

- Using calibration tools and profiles to ensure color consistency.

- Understanding color models (CMYK, RGB, etc.) and their impact on print quality.

15. How do you ensure safety and follow environmental regulations in the print shop?

- Properly handling chemicals and hazardous materials.

- Wearing appropriate safety gear.

- Following established safety protocols.

- Complying with environmental regulations for waste disposal and emissions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Offset Lithographic Press Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Offset Lithographic Press Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Offset Lithographic Press Setters are professionals responsible for preparing and operating offset lithographic printing presses to produce high-quality printed materials such as brochures, magazines, and packaging.

1. Setting and Preparing Printing Equipment

Prepare and set printing plates on printing presses.

- Operate and adjust press controls to achieve desired printing quality.

- Monitor printing processes to ensure consistent print quality and efficiency.

2. Maintaining Press Equipment

Regularly maintain and troubleshoot presses to minimize downtime.

- Conduct preventive maintenance tasks such as cleaning, lubricating, and inspecting presses.

- Troubleshoot and resolve press malfunctions to ensure smooth operations.

3. Quality Control and Troubleshooting

Monitor printing quality and troubleshoot any issues that may arise.

- Inspect printed materials for quality and accuracy.

- Identify and resolve defects such as smudging, misregistration, and poor color matching.

4. Safety and Compliance

Follow established safety protocols to operate and maintain printing equipment.

- Ensure compliance with health and safety regulations related to printing operations.

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

Preparing for an interview can help you showcase your skills and experience in the best possible light. Here are some tips to help you ace your interview for an Offset Lithographic Press Setter position:

1. Research the Company and Position

Familiarize yourself with the company’s history, culture, and products or services.

- Research the specific role and its responsibilities to demonstrate your understanding of the position.

2. Practice and Prepare for Common Interview Questions

Anticipate typical interview questions and prepare thoughtful responses.

- Practice answering questions about your experience, skills, and knowledge of offset lithographic printing.

- Prepare examples of your troubleshooting abilities and quality control measures.

3. Highlight Your Press Operating Skills and Experience

Emphasize your expertise in operating offset lithographic presses and any specialized knowledge you possess.

- Quantify your accomplishments, using specific metrics to demonstrate your impact.

- Be prepared to discuss your proficiency in press setup, maintenance, and troubleshooting.

4. Showcase Your Troubleshooting Abilities

Highlight your problem-solving skills and ability to identify and resolve press issues.

- Provide examples of how you have diagnosed and fixed printing problems.

- Explain your approach to troubleshooting and maintaining press equipment.

5. Demonstrate Your Attention to Detail

Emphasize your meticulous nature and ability to maintain high-quality standards.

- Highlight your experience in inspecting printed materials and ensuring accuracy.

- Discuss your commitment to following safety protocols and maintaining a clean work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Offset Lithographic Press Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.