Feeling lost in a sea of interview questions? Landed that dream interview for Printer Slotter Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Printer Slotter Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

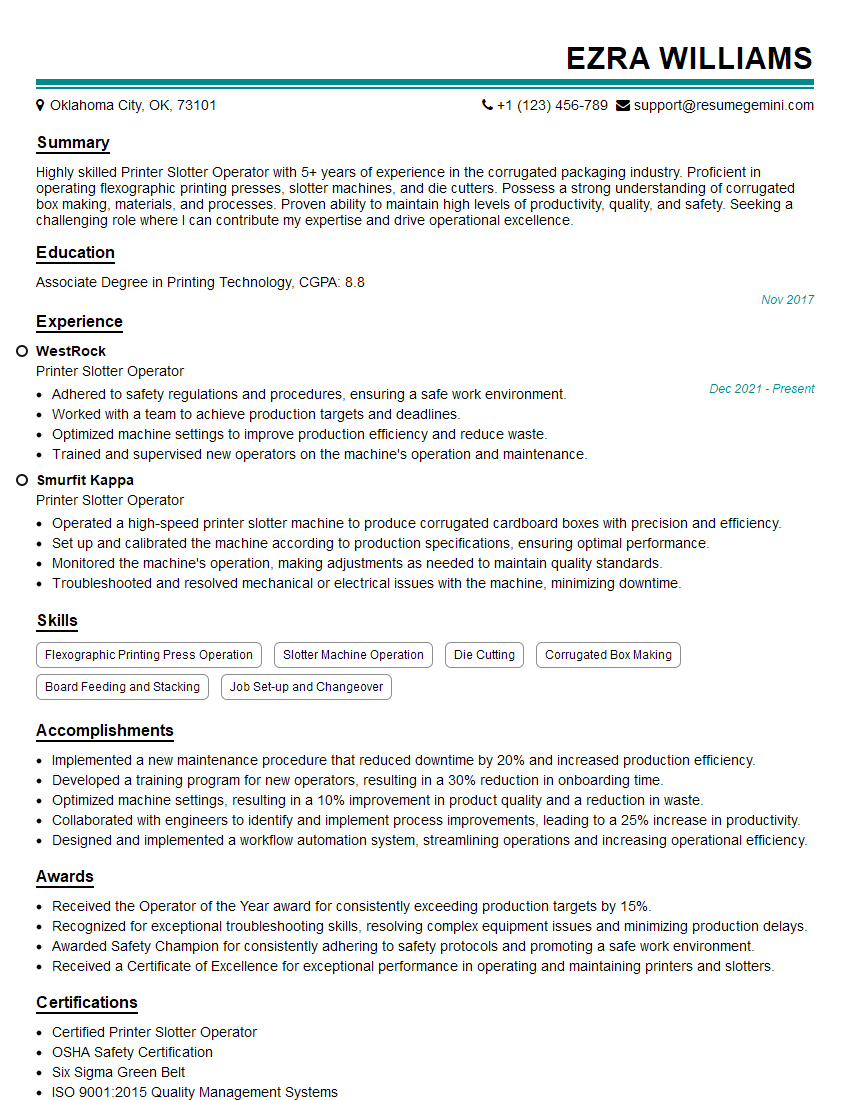

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printer Slotter Operator

1. What are the key responsibilities of a Printer Slotter Operator?

As a Printer Slotter Operator, my core responsibilities encompass:

- Operating and maintaining the printer slotter machine to produce corrugated boxes efficiently.

- Setting up and adjusting the machine according to job requirements, including die changes and ink adjustments.

- Monitoring the printing and slotting process to ensure optimal quality and productivity.

- Performing regular maintenance and troubleshooting to minimize downtime and optimize machine performance.

- Ensuring adherence to safety protocols and maintaining a clean and organized work area.

2. Describe the different types of corrugated cardboard and their applications.

Types of Corrugated Cardboard:

- Single Wall: Used for lightweight packaging, such as boxes for electronics or food items.

- Double Wall: Provides added strength and durability for heavy-duty packaging, such as boxes for appliances or furniture.

- Triple Wall: Offers the highest level of protection for extremely heavy or fragile items, such as industrial equipment or artwork.

Applications:

- Single Wall: Shipping boxes, product displays, mailing envelopes.

- Double Wall: Moving boxes, furniture packaging, protective padding.

- Triple Wall: Heavy machinery packaging, sensitive equipment protection, military applications.

3. Explain the process of die cutting in corrugated box production.

Die cutting involves using a sharp metal die to cut and crease the corrugated cardboard into the desired shape of the box. The process typically includes the following steps:

- Selecting the appropriate die for the job.

- Positioning the die on the printer slotter machine.

- Feeding the corrugated board through the machine.

- Applying pressure to cut and crease the board according to the die design.

- Removing the cut and creased blanks for assembly.

4. What are the common issues that may arise during the printing and slotting process, and how do you troubleshoot them?

- Printing Issues: Ink smudging, color inconsistencies, registration errors.

- Slotting Issues: Poor slot quality, misaligned slots, tearing of cardboard.

Troubleshooting:

- Check ink levels and adjust as needed.

- Inspect printing plates for damage or wear.

- Calibrate the machine to ensure proper registration.

- Adjust cutter settings to improve slot quality.

- Lubricate moving parts to reduce friction and prevent tearing.

5. Describe the quality control measures you implement to ensure the production of high-quality corrugated boxes.

To maintain quality standards, I adhere to the following measures:

- Pre-Production: Inspecting raw materials, verifying die specifications, and calibrating the machine.

- During Production: Monitoring printing quality, checking slot accuracy, and performing random inspections.

- Post-Production: Conducting final product inspections to ensure compliance with customer requirements and industry standards.

- Documentation: Maintaining records of quality control checks and corrective actions taken.

- Continuous Improvement: Regularly reviewing processes and implementing improvements to enhance quality.

6. How do you manage safety protocols and minimize risks in the operation of the printer slotter machine?

- Personal Protective Equipment: Wearing appropriate PPE, including safety glasses, gloves, and earplugs.

- Machine Safety: Following lockout/tagout procedures, maintaining guards and barriers, and reporting any potential hazards.

- Ergonomics: Using proper lifting techniques and maintaining a clean and organized workspace to prevent accidents.

- Emergency Response: Familiarizing myself with emergency procedures, evacuation routes, and first aid protocols.

- Training: Regularly participating in safety training to stay updated on best practices and regulations.

7. What are the recent advancements in printer slotter technology that you are aware of?

- Digital Die Cutting: Using digital technology to create dies, reducing setup time and increasing flexibility.

- Inline Quality Control: Integrating sensors and cameras into the machine for real-time monitoring and automatic defect detection.

- Automated Feeders and Stackers: Improving efficiency and reducing manual labor.

- Sustainable Materials: Utilizing eco-friendly corrugated cardboard options to reduce environmental impact.

- IoT Connectivity: Enabling remote monitoring and predictive maintenance to optimize production and minimize downtime.

8. Can you explain the importance of preventive maintenance in ensuring the longevity and optimal performance of the printer slotter machine?

Preventive maintenance is crucial for several reasons:

- Reduced Downtime: Regular maintenance helps identify and address potential issues before they become major breakdowns.

- Extended Equipment Life: Proper maintenance prolongs the lifespan of the machine, reducing replacement costs.

- Improved Productivity: A well-maintained machine operates more efficiently, leading to increased productivity and output.

- Safety: Regular inspections and maintenance help prevent accidents and ensure a safe work environment.

- Cost Savings: Preventive maintenance is often more cost-effective than reactive repairs.

9. What are the key performance indicators (KPIs) that you focus on to measure your effectiveness as a Printer Slotter Operator?

- Production Output: Meeting or exceeding daily production targets.

- Quality Control: Maintaining a high percentage of defect-free products.

- Machine Uptime: Maximizing machine utilization and minimizing downtime.

- Material Usage: Optimizing material usage and minimizing waste.

- Safety Compliance: Adhering to safety protocols and maintaining a safe work environment.

10. In a fast-paced production environment, how do you prioritize tasks and manage multiple responsibilities effectively?

- Prioritization: Assessing the importance and urgency of tasks to determine the most critical ones.

- Time Management: Utilizing time management techniques, such as the Pomodoro Technique, to optimize productivity.

- Delegation: Collaborating with colleagues and delegating tasks when appropriate to maximize efficiency.

- Communication: Communicating effectively with supervisors and colleagues to resolve issues and coordinate tasks.

- Flexibility: Adapting quickly to changing priorities and adjusting my schedule as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printer Slotter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printer Slotter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Printer Slotter Operator is a skilled professional responsible for operating printer slotter machines in a manufacturing setting. The key job responsibilities of a Printer Slotter Operator include:1. Machine Operation

Setting up, operating, and maintaining printer slotter machines to produce corrugated cardboard boxes.

- Loading and adjusting paper rolls onto the machine.

- Inspecting paper for defects and making necessary adjustments.

- Monitoring machine operations and making adjustments as needed to ensure smooth production.

2. Quality Control

Inspecting and ensuring the quality of the printed and slotted cardboard boxes produced.

- Verifying the accuracy of printing, slotting, and scoring.

- Identifying and removing any defective boxes from the production line.

- Reporting any quality issues to supervisors for resolution.

3. Safety and Maintenance

Maintaining a safe and clean work area and following all safety protocols.

- Performing regular maintenance and cleaning of the printer slotter machine.

- Lubricating moving parts and replacing worn-out components.

- Reporting any safety hazards or equipment malfunctions to supervisors.

4. Production Optimization

Assisting in the optimization of production efficiency by identifying areas for improvement.

- Analyzing production data to identify bottlenecks and inefficiencies.

- Making suggestions for process improvements and implementing changes.

- Collaborating with other operators and supervisors to improve communication and coordination.

Interview Tips

To ace an interview for a Printer Slotter Operator position, candidates should prepare thoroughly and follow these tips:1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry.

- Visit the company website and review its mission statement, values, and recent announcements.

- Read industry publications and news articles to stay updated on trends.

- Prepare questions about the company’s growth plans and market position.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in operating printer slotter machines.

- Quantify your accomplishments using specific metrics and examples.

- Discuss any experience with quality control, safety procedures, and production optimization.

- Mention any certifications or training programs you have completed.

3. Demonstrate Passion for the Role

Convey your interest in the field and your eagerness to learn and grow.

- Explain why you are passionate about manufacturing and the role of a Printer Slotter Operator.

- Share your goals and ambitions within the company and the industry.

- Highlight your willingness to take on additional responsibilities and contribute to the team.

4. Be Prepared to Answer Common Interview Questions

Practice answering commonly asked questions, such as:

- “Describe your experience operating printer slotter machines.”

- “How do you ensure the quality of the printed and slotted cardboard boxes produced?”

- “What are your strengths and weaknesses as a Printer Slotter Operator?”

- “Why are you interested in this position and our company?”

- “What are your salary expectations?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printer Slotter Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.