Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Printing Press Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

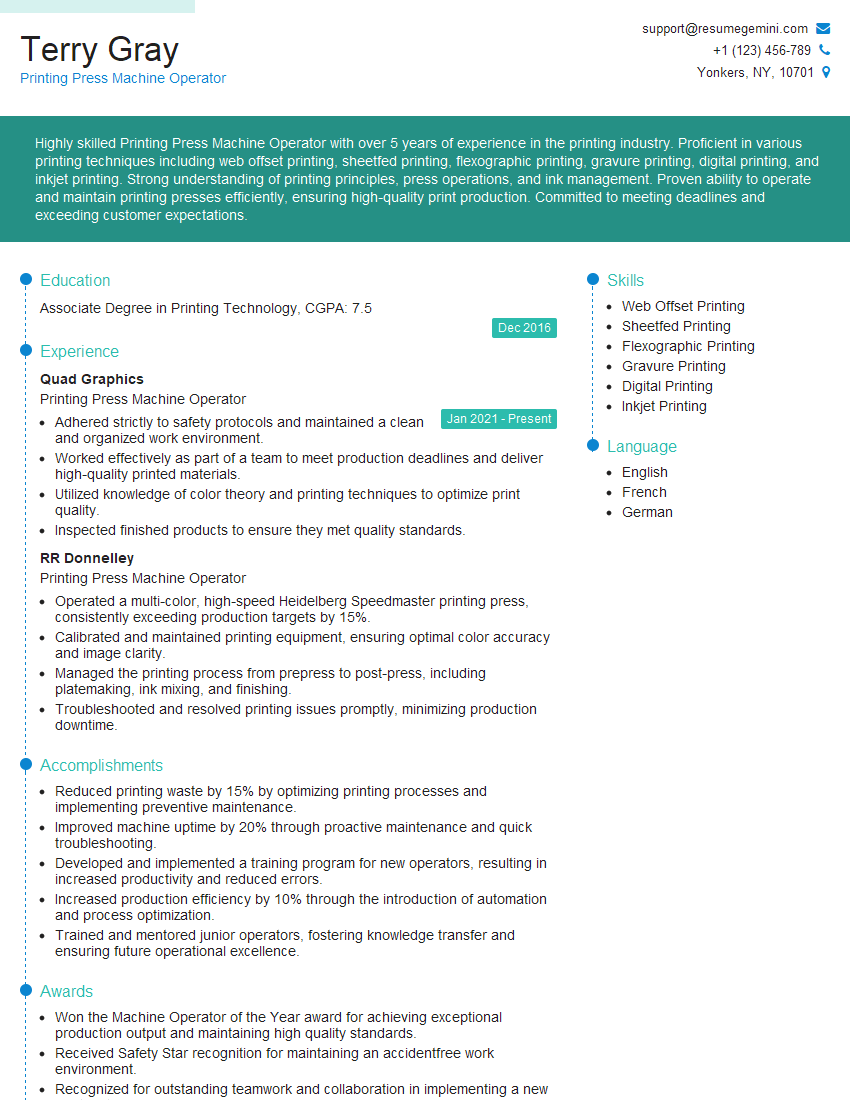

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printing Press Machine Operator

1. Explain the key responsibilities of a Printing Press Machine Operator?

The key responsibilities of a Printing Press Machine Operator include:

- Setting up and operating printing presses to produce high-quality printed materials

- Loading and unloading paper stock

- Adjusting and maintaining printing presses

- Monitoring printing processes and making necessary adjustments

- Inspecting printed materials for quality and accuracy

- Maintaining a clean and safe work area

2. Describe the different types of printing presses and their uses?

Digital presses

- Use digital technology to create images directly onto paper

- Produce high-quality, full-color prints

- Ideal for short-run printing jobs

Offset presses

- Use metal plates to transfer images onto paper

- Produce high-volume, high-quality prints

- Ideal for long-run printing jobs

Screen printing presses

- Use a mesh screen to transfer ink onto paper

- Produce durable, long-lasting prints

- Ideal for printing on fabrics, plastics, and other materials

3. What are the safety precautions that should be taken when operating a printing press?

The following safety precautions should be taken when operating a printing press:

- Wear appropriate safety gear, including gloves and safety glasses

- Never put your hands or fingers near moving parts

- Keep the work area clean and free of debris

- Follow all manufacturer’s instructions for operating the printing press

- Be aware of potential hazards, such as electrical shocks and paper cuts

4. What are some of the common problems that can occur when operating a printing press and their solutions?

Some common problems that can occur when operating a printing press include:

- Paper jams: This can be caused by using the wrong type of paper, loading the paper incorrectly, or a faulty paper feed mechanism. To resolve a paper jam, carefully remove the jammed paper and restart the printing process.

- Ink smudging: This can be caused by using too much ink, the ink not drying properly, or a faulty ink roller. To resolve ink smudging, adjust the ink flow, allow the ink to dry completely before handling the prints, or replace the ink roller.

- Registration errors: This can be caused by the paper not being aligned properly with the printing plate. To resolve registration errors, adjust the paper guides and restart the printing process.

5. What are the different types of paper that can be used in a printing press?

The different types of paper that can be used in a printing press include:

- Bond paper: A high-quality paper with a smooth surface, ideal for printing documents and presentations

- Coated paper: A paper with a glossy or matte coating, ideal for printing high-quality images and graphics

- Newsprint: A low-cost paper with a rough surface, ideal for printing newspapers and other low-cost publications

- Cardstock: A thick, durable paper, ideal for printing business cards, postcards, and other marketing materials

6. What are the different types of ink that can be used in a printing press?

The different types of ink that can be used in a printing press include:

- Offset ink: A type of ink that is used in offset printing presses, which is a common printing method for high-volume printing

- Digital ink: A type of ink that is used in digital printing presses, which is a newer printing method that is ideal for short-run printing jobs

- Letterpress ink: A type of ink that is used in letterpress printing presses, which is a traditional printing method that creates a raised impression on the paper

7. What are the different finishing processes that can be used on printed materials?

The different finishing processes that can be used on printed materials include:

- Die cutting: A process that uses a die to cut the paper into a specific shape

- Foil stamping: A process that uses a heated die to apply a metallic foil to the paper

- Embossing: A process that creates a raised design on the paper

- Laminating: A process that applies a thin layer of plastic to the paper to protect it from moisture and wear

8. What are the key factors to consider when choosing a printing press?

The key factors to consider when choosing a printing press include:

- The type of printing you will be doing: If you will be printing high-volume jobs, you will need a press that is designed for high-speed printing. If you will be printing short-run jobs, you can choose a press that is more affordable and compact.

- The size of the paper you will be printing: The size of the press will depend on the size of the paper you will be printing. If you will be printing large sheets of paper, you will need a press that is large enough to accommodate the paper size.

- The quality of the printing you require: If you need high-quality printing, you will need a press that is equipped with advanced features such as automatic registration and color correction.

9. What are the advantages of using a printing press over other printing methods?

The advantages of using a printing press over other printing methods include:

- Higher quality printing: Printing presses produce higher quality prints than other printing methods, such as inkjet printers and laser printers.

- Higher speed printing: Printing presses can print large volumes of paper quickly and efficiently.

- Lower cost per print: Printing presses have a lower cost per print than other printing methods, especially for high-volume printing jobs.

10. What are the latest trends in printing press technology?

The latest trends in printing press technology include:

- Digital printing: Digital printing is a newer printing method that uses digital technology to create images directly onto paper. Digital printing is ideal for short-run printing jobs and produces high-quality prints.

- Hybrid printing: Hybrid printing is a combination of digital printing and offset printing. Hybrid printing presses can print both digital and offset jobs, offering the best of both worlds.

- Green printing: Green printing is a focus on using environmentally friendly printing practices. Green printing presses use less energy and produce less waste.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printing Press Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printing Press Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Printing Press Machine Operator is responsible for the operation and maintenance of printing presses, ensuring efficient production of printed materials. The key responsibilities include:

1. Machine Operation

Operate printing presses to print diverse materials, such as paper, plastic, and fabric.

- Setup and adjust printing machines according to job specifications.

- Monitor printing processes, ensuring quality and efficiency.

2. Maintenance and Repair

Perform routine maintenance and repairs on printing machines to prevent breakdowns.

- Inspect and clean machines regularly.

- Identify and resolve mechanical or electrical malfunctions.

3. Quality Control

Inspect printed materials for quality, ensuring compliance with standards.

- Monitor color accuracy, registration, and overall print quality.

- Make adjustments to printing processes as needed to maintain quality.

4. Safety and Environment

Follow safety protocols and maintain a clean and safe work environment.

- Wear appropriate safety gear and follow established procedures.

- Dispose of waste materials in an environmentally responsible manner.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some effective interview tips:

1. Research the Company and Position

Take time to learn about the company’s history, values, and industry standing. Familiarize yourself with the specific requirements of the Printing Press Machine Operator position.

- Visit the company website and social media pages.

- Read industry news and articles related to printing technology.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your responses in advance. This will help you deliver clear and concise answers during the interview.

- Tell me about your experience operating printing presses.

- Describe a time you resolved a technical issue with a printing machine.

- How do you ensure the quality of printed materials?

3. Showcase Your Skills and Experience

Highlight your relevant skills and experience during the interview. Provide specific examples to demonstrate your capabilities as a Printing Press Machine Operator.

- Quantify your accomplishments whenever possible, using specific metrics.

- Emphasize your ability to work independently and as part of a team.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. It also gives you an opportunity to clarify any details about the role or company.

- Inquire about the company’s growth plans or recent industry trends.

- Ask about opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printing Press Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!