Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Printing Press Operator Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

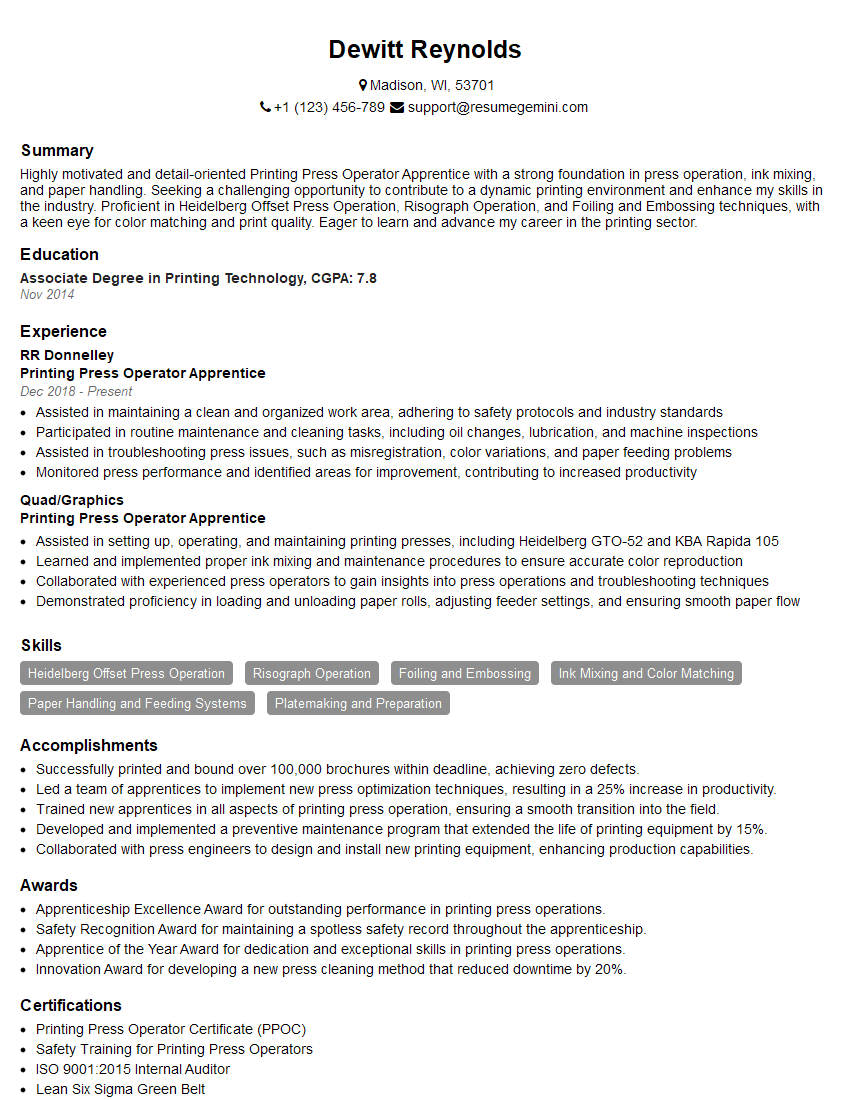

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printing Press Operator Apprentice

1. Describe the process of preparing a printing press for a new job.

Preparing a printing press for a new job involves several steps:

- Gather materials: Collect the necessary materials for the job, including paper, ink, plates, and chemicals.

- Clean the press: Wipe down the press bed, ink rollers, and other components to remove any debris or ink residue.

- Mount the plates: Secure the printing plates onto the press cylinders, ensuring proper alignment.

- Adjust the press settings: Set the press speed, ink flow, and paper feed according to the job specifications.

- Test run: Perform a short test run to check for any issues with registration, color accuracy, or paper alignment.

2. Explain the different types of printing presses and their applications.

Web presses

- High-speed presses that print large quantities of newspapers, magazines, and brochures.

- Use rolls of paper instead of individual sheets.

Sheet-fed presses

- Print on individual sheets of paper.

- Used for smaller print runs and higher quality printing.

Digital presses

- Produce digital images directly onto paper or other substrates.

- Offer variable data printing and quick turnaround times.

3. Discuss the importance of color management in printing.

Color management ensures consistent and accurate color reproduction throughout the printing process:

- Color calibration: Calibrating your printing press and monitor ensures that colors are displayed and printed accurately.

- Color profiles: Creating color profiles for different devices and substrates helps match colors across different platforms.

- Proofing: Creating and approving proofs allows you to verify color accuracy before mass production.

4. Describe the different paper types used in printing and their properties.

- Bond paper: Standard office paper with moderate brightness and opacity.

- Offset paper: High-quality paper with smooth surface and good ink absorption.

- Coated paper: Paper coated with a layer of clay or plastic to improve gloss, smoothness, and ink adhesion.

- Newsprint: Low-cost paper used for newspapers due to its high porosity and absorbency.

5. Explain the process of troubleshooting common printing problems and how to resolve them.

- Paper jams: Check for obstructions in the paper path, adjust paper feed settings, or remove and replace torn paper.

- Registration issues: Realign the printing plates, adjust the paper guides, or correct the press settings.

- Color imbalances: Calibrate the press, clean the ink rollers, or adjust the ink flow.

- Smudging: Adjust the drying time, use different paper, or check for excess ink.

6. Discuss the role of maintenance in ensuring press uptime and quality.

- Regular cleaning: Cleaning the press regularly removes ink residue, dust, and debris that can cause printing problems.

- Preventive maintenance: Scheduled inspections and maintenance help detect and resolve potential issues before they become major problems.

- Lubrication: Lubricating moving parts ensures smooth operation and reduces wear and tear.

- Calibration: Regular calibration of the press settings ensures accurate and consistent printing quality.

7. Describe the safety procedures to be followed when operating a printing press.

- Wear personal protective equipment: Gloves, safety glasses, and closed-toe shoes protect against ink and paper hazards.

- Lock out/tag out: Ensure the press is isolated from power before performing maintenance.

- Keep hands clear: Avoid placing hands near moving parts during operation.

- Be aware of pinch points: Identify potential pinch points and take precautions to avoid injury.

8. Explain the importance of waste reduction in printing and how it can be achieved.

- Reduce paper waste: Optimize paper usage by selecting the appropriate sheet sizes and minimizing trim waste.

- Recycle paper: Establish a recycling program to collect and recycle waste paper.

- Reuse ink: Implement ink recycling programs to minimize ink waste.

- Use eco-friendly materials: Opt for paper and inks that meet environmental standards.

9. Discuss the latest trends in printing technology and how they impact the industry.

- Digital printing: Growing popularity due to its flexibility, variable data printing capabilities, and shorter turnaround times.

- Automation: Integration of automated systems to streamline processes, improve efficiency, and reduce labor costs.

- Sustainability: Focus on eco-friendly printing practices, such as waste reduction, energy efficiency, and the use of sustainable materials.

10. How do you stay updated on the latest advancements in printing techniques and technologies?

- Attend industry events and conferences: Network with experts and learn about the latest trends.

- Read trade publications and online resources: Stay informed about new technologies and best practices.

- Engage in continuing education: Participate in workshops, seminars, or online courses to expand your knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printing Press Operator Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printing Press Operator Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Printing Press Operator Apprentices assist in a variety of tasks related to the operation of printing presses in a printing company or other similar establishment. Under the supervision of an experienced operator, they perform tasks such as:

1. Machine Setup

Setting up and adjusting printing presses according to job specifications, including loading paper, setting ink levels, and adjusting press settings.

- Verifying that the press is properly set up and calibrated.

- Loading and unloading paper rolls.

- Setting ink levels and adjusting press settings.

- Ensuring that the press is running smoothly and efficiently.

2. Printing Process

Monitoring the printing process and making adjustments as needed to ensure that the output meets quality standards.

- Monitoring the printing process and making adjustments as needed.

- Inspecting printed materials for defects.

- Maintaining the cleanliness of the press and work area.

- Assisting with troubleshooting and resolving printing problems.

3. Maintenance and Repair

Performing basic maintenance and repair tasks on printing presses, such as cleaning, lubricating, and replacing parts.

- Cleaning and lubricating the press.

- Replacing worn or damaged parts.

- Performing minor repairs.

- Assisting with major repairs.

4. Quality Control

Inspecting printed materials for defects and ensuring that they meet quality standards.

- Inspecting printed materials for defects.

- Ensuring that printed materials meet quality standards.

- Maintaining records of quality control checks.

- Reporting any quality issues to the supervisor.

Interview Tips

Preparing for a job interview can be a daunting task, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace your interview for a Printing Press Operator Apprentice position:

1. Research the Company and Position

Before you go into your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate. You can find this information on the company’s website, social media pages, and Glassdoor.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully to understand the specific requirements of the position.

- Check out the company’s social media pages to get a sense of their culture and employee engagement.

- Read reviews of the company on Glassdoor to learn about the experiences of current and former employees.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Write out your answers to common interview questions and practice delivering them out loud.

- Ask a friend or family member to conduct a mock interview with you.

- Use the STAR method to answer behavioral interview questions.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also avoid wearing excessive jewelry or perfume/cologne.

- Wear a suit or dress pants and a button-down shirt or blouse.

- Make sure your clothes are clean and pressed.

- Avoid wearing excessive jewelry or perfume/cologne.

- Be well-groomed and have a neat haircut.

4. Be Punctual

Punctuality is important for any job interview, but it is especially important for a Printing Press Operator Apprentice position. This is because printing presses are often used on tight deadlines, and employers need to know that you are reliable and can be counted on to be on time.

- Plan your route to the interview in advance and allow yourself plenty of time to get there.

- If you are running late, call the interviewer to let them know.

- Be prepared to wait a few minutes if the interviewer is running behind.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Printing Press Operator Apprentice, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Printing Press Operator Apprentice positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.