Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rolling Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

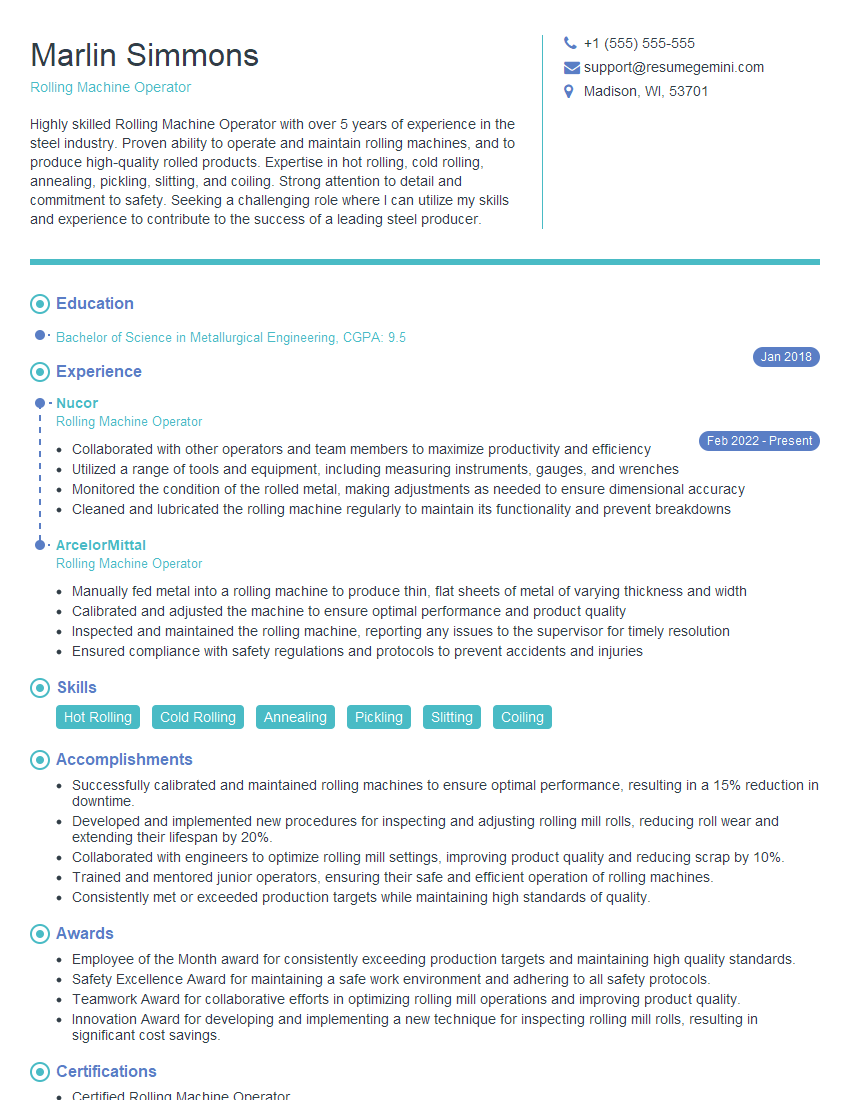

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rolling Machine Operator

1. Describe the key technical skills required to operate a rolling machine effectively?

Key technical skills required to operate a rolling machine effectively include:

- Understanding of rolling mill operations

- Knowledge of different types of rolling machines

- Ability to calibrate and adjust rolling machine settings

- Skill in monitoring and controlling rolling processes

- Troubleshooting and maintenance of rolling machines

2. Explain the process of setting up a rolling machine for a specific job?

Material Preparation:

- Select the appropriate material for the job

- Prepare the material by cleaning and removing any surface impurities

Machine Setup:

- Set the roll gap according to the desired thickness

- Set the rolling speed and tension

- Calibrate the sensors for monitoring

Pre-rolling Checks:

- Ensure the machine is lubricated

- Check all safety features

- Run a test roll to verify settings

3. How do you ensure the quality of the rolled product?

To ensure the quality of the rolled product, I follow these steps:

- Monitor the rolling process closely

- Inspect the rolled product for defects

- Make adjustments to the rolling machine as needed

- Follow established quality control procedures

- Calibrate and maintain the measurement instruments regularly

4. What are the safety precautions that need to be taken when operating a rolling machine?

The following safety precautions should be taken when operating a rolling machine:

- Wear appropriate personal protective equipment (PPE)

- Keep the work area clean and organized

- Never operate the machine when it is not in good working order

- Be aware of the pinch points and other hazards

- Follow all safety procedures and guidelines

5. What are the preventive maintenance tasks that you perform on a rolling machine?

Preventive maintenance tasks that I perform on a rolling machine include:

- Regularly lubricating all moving parts

- Checking and adjusting the roll gap

- Monitoring the oil levels

- Cleaning the machine and removing any debris

- Inspecting the machine for any signs of wear or damage

6. How do you troubleshoot common problems that occur during rolling operations?

To troubleshoot common problems during rolling operations, I:

- Identify the problem and its symptoms

- Refer to the machine’s troubleshooting guide

- Check the machine’s settings and adjust as needed

- Inspect the machine for any signs of wear or damage

- Consult with a supervisor or mechanic if the problem persists

7. What is the role of automation in modern rolling mills?

Automation plays a crucial role in modern rolling mills, providing benefits such as:

- Increased productivity

- Improved product quality

- Reduced labor costs

- Enhanced safety

- Reduced downtime

8. What are the different types of rolling mills used in the industry?

Different types of rolling mills used in the industry include:

- Hot rolling mills

- Cold rolling mills

- Tandem mills

- Reversing mills

- Shape rolling mills

9. How do you calculate the rolling force required for a given material?

The rolling force required for a given material can be calculated using the following formula:

Rolling Force = (Yield Strength of Material x Material Thickness x Roll Radius) / Coefficient of Friction

10. What are the different roll materials used in rolling mills?

Different roll materials used in rolling mills include:

- Steel

- Alloyed Steel

- Cast Iron

- Ceramics

- Composite Materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rolling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rolling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rolling Machine Operator plays a pivotal role in the manufacturing process, operating sophisticated machinery to produce a wide range of products, from metal sheets to plastic films.

1. Machine Operation

The primary responsibility of a Rolling Machine Operator is to set up, operate, and monitor rolling machines as per established specifications and quality standards.

- Load raw materials, adjust machine settings, and initiate the rolling process.

- Monitor machine performance, make necessary adjustments to ensure optimal production.

2. Quality Control

Ensuring the quality of the final product is paramount. Rolling Machine Operators:

- Inspect raw materials and finished products for defects.

- Conduct routine maintenance and calibration checks on machines.

3. Production Management

Responsibilities extend beyond machine operation, including:

- Maintaining production schedules and optimizing machine efficiency.

- Monitoring material inventory and adjusting production accordingly.

4. Safety and Maintenance

Ensuring a safe and efficient work environment is crucial:

- Adhere to safety protocols, wear protective gear, and follow established procedures.

- Perform regular maintenance and cleaning on machinery and equipment.

Interview Tips

Preparing for an interview can be daunting, but with the right approach, you can increase your chances of success.

1. Research the Company and Position

Thoroughly research the company, industry, and specific job requirements. This will enable you to speak intelligently about your qualifications and demonstrate your interest in the position.

- Visit the company’s website, read their mission statement, and explore their products or services.

- Review the job description carefully, identifying key skills and responsibilities required for the role.

2. Practice Your Answers

Take time to prepare thoughtful answers to common interview questions. Practice delivering your responses confidently and concisely.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples from your past experience.

- Consider potential questions about your technical skills, experience with rolling machines, and commitment to quality.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments with specific metrics whenever possible.

- Showcase your expertise in operating and maintaining rolling machines.

- Demonstrate your understanding of quality control procedures and your ability to produce high-quality products.

4. Prepare Questions for the Interviewer

Asking well-thought-out questions shows your engagement and interest in the position. Prepare a few questions that demonstrate your eagerness to learn more about the company and the role.

- Inquire about the company’s growth plans and industry outlook.

- Ask about specific projects or initiatives that align with your skills and interests.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rolling Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.