Are you gearing up for a career in Rotoprinter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rotoprinter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

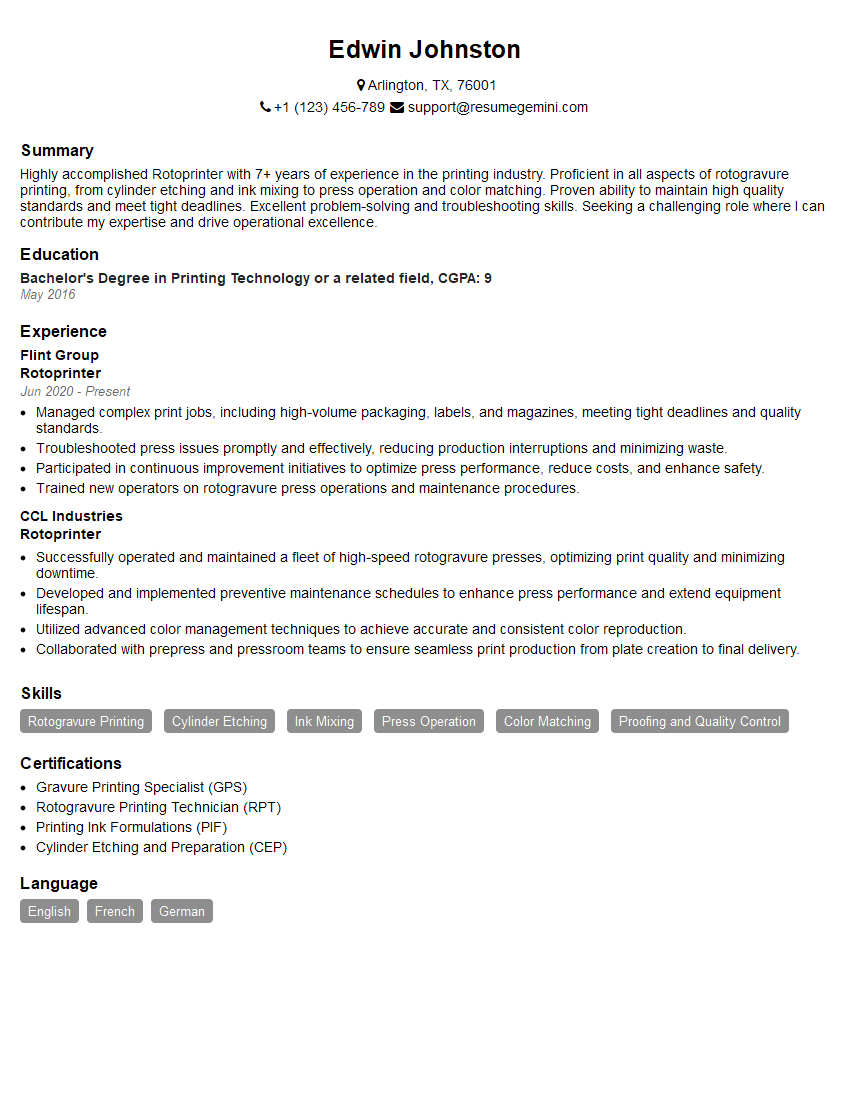

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotoprinter

1. Explain the process of rotogravure printing.

- Rotogravure printing, also known as gravure printing, is an intaglio printing process where the image areas are engraved or etched into a metal cylinder.

- The engraved cylinder is then inked and the excess ink is wiped away leaving ink only in the recessed areas.

- The paper is then passed through the press and the ink is transferred from the cylinder to the paper.

2. What are the advantages of rotogravure printing?

- High-quality printing with accurate color reproduction.

- Long print runs possible with minimal downtime.

- Suitable for printing on a wide variety of substrates.

- Cost-effective for large volume printing.

Disadvantages:

- High initial setup costs due to the need for specialized equipment and engraved cylinders.

- Not suitable for short print runs.

- Complex process requiring skilled operators.

3. What factors influence the quality of rotogravure printing?

- Quality of the engraved cylinder.

- Ink viscosity and tack.

- Paper quality and surface characteristics.

- Press conditions such as speed and pressure.

- Skill of the operator.

4. Describe the different types of cylinders used in rotogravure printing.

- Steel cylinders: Hard and durable, suitable for long print runs.

- Copper cylinders: Softer than steel, allowing for finer details and better image quality.

- Ceramic cylinders: Non-porous and resistant to wear, used for printing on plastic films and other non-absorbent substrates.

5. Explain the process of cylinder engraving for rotogravure printing.

- The cylinder is first coated with a photosensitive material.

- A film positive of the image is placed on the cylinder and exposed to light.

- The exposed areas of the photosensitive coating harden, while the unexposed areas are washed away.

- The remaining hardened areas are etched into the cylinder using a chemical solution.

6. What is the role of the doctor blade in rotogravure printing?

- The doctor blade is a thin, flexible blade that removes excess ink from the engraved cylinder before it comes into contact with the paper.

- The angle and pressure of the doctor blade are critical to achieving optimal ink transfer and print quality.

7. Describe the different types of inks used in rotogravure printing.

- Solvent-based inks: Fast-drying and produce vibrant colors.

- Water-based inks: More environmentally friendly but require longer drying times.

- UV-curable inks: Cure instantly when exposed to UV light, allowing for higher press speeds.

8. What are the safety precautions that must be observed in rotogravure printing?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and respirators when handling chemicals.

- Ensure proper ventilation to avoid exposure to harmful fumes.

- Store and dispose of chemicals safely according to manufacturer’s instructions.

- Follow lockout/tagout procedures when servicing or repairing equipment.

9. What is the role of quality control in rotogravure printing?

- Inspecting incoming materials and equipment.

- Monitoring press conditions and making adjustments as needed.

- Checking print samples regularly to ensure color accuracy, registration, and other quality parameters.

- Implementing corrective actions to resolve any quality issues.

10. What trends are emerging in rotogravure printing technology?

- Digital cylinder engraving for faster and more accurate cylinder production.

- Development of new inks and coatings with improved environmental performance.

- Integration of automation and robotics for increased efficiency and productivity.

- Exploration of new applications such as printing on flexible packaging and electronics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotoprinter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotoprinter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rotoprinters are responsible for operating rotogravure printing presses, which are used to produce high-quality images on a variety of materials, such as paper, plastic, and metal.

1. Prepress Operations

In the prepress stage, rotoprinters are responsible for preparing the printing plates. This includes creating and editing digital files, and transferring the images to the printing plates.

- Create and edit digital files using graphic design software

- Transfer images to printing plates using a computer-to-plate (CTP) system

2. Printing Operations

Rotoprinters operate rotogravure printing presses to print images on a variety of materials. This involves setting up the press, loading the printing plates, and monitoring the printing process.

- Set up the rotogravure printing press according to the printing job specifications

- Load the printing plates onto the press

- Monitor the printing process and make adjustments as needed

3. Postpress Operations

After the printing process is complete, rotoprinters are responsible for finishing the printed materials. This includes cutting, folding, and binding the materials.

- Cut the printed materials to the desired size and shape

- Fold the printed materials into the desired format

- Bind the printed materials together using a variety of methods

4. Quality Control

Rotoprinters are responsible for ensuring that the printed materials meet the required quality standards. This involves inspecting the materials for defects and making adjustments to the printing process as needed.

- Inspect the printed materials for defects, such as smudges, streaks, and misprints

- Make adjustments to the printing process as needed to ensure that the printed materials meet the required quality standards

Interview Tips

Preparing for an interview for a rotoprinter position can be daunting, but by following some simple tips and tricks, you can increase your chances of success.

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific rotoprinter position you are applying for. This will help you to understand the company’s culture, values, and goals, as well as the specific responsibilities of the role.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read online reviews of the company to get a sense of their culture and employee satisfaction.

- Review the job description carefully to identify the key requirements of the role.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked during an interview for a rotoprinter position. By practicing your answers to these questions in advance, you can increase your confidence and deliver more polished and articulate responses.

- Tell me about your experience with rotogravure printing.

- What are your strengths and weaknesses as a rotoprinter?

- Why are you interested in working for our company?

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of an interview is a great way to show the interviewer that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- What are the biggest challenges facing the rotogravure printing industry today?

- What are the most important qualities you are looking for in a rotoprinter?

- What is the company’s culture like?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Wear a suit or business casual attire.

- Be punctual for your interview.

- Make eye contact with the interviewer and give a firm handshake.

5. Be Yourself and Be Confident

The most important thing is to be yourself and be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

- Be honest and authentic in your answers.

- Show the interviewer that you are confident in your abilities.

- Be enthusiastic and positive about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rotoprinter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.