Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rotary Screen Printing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

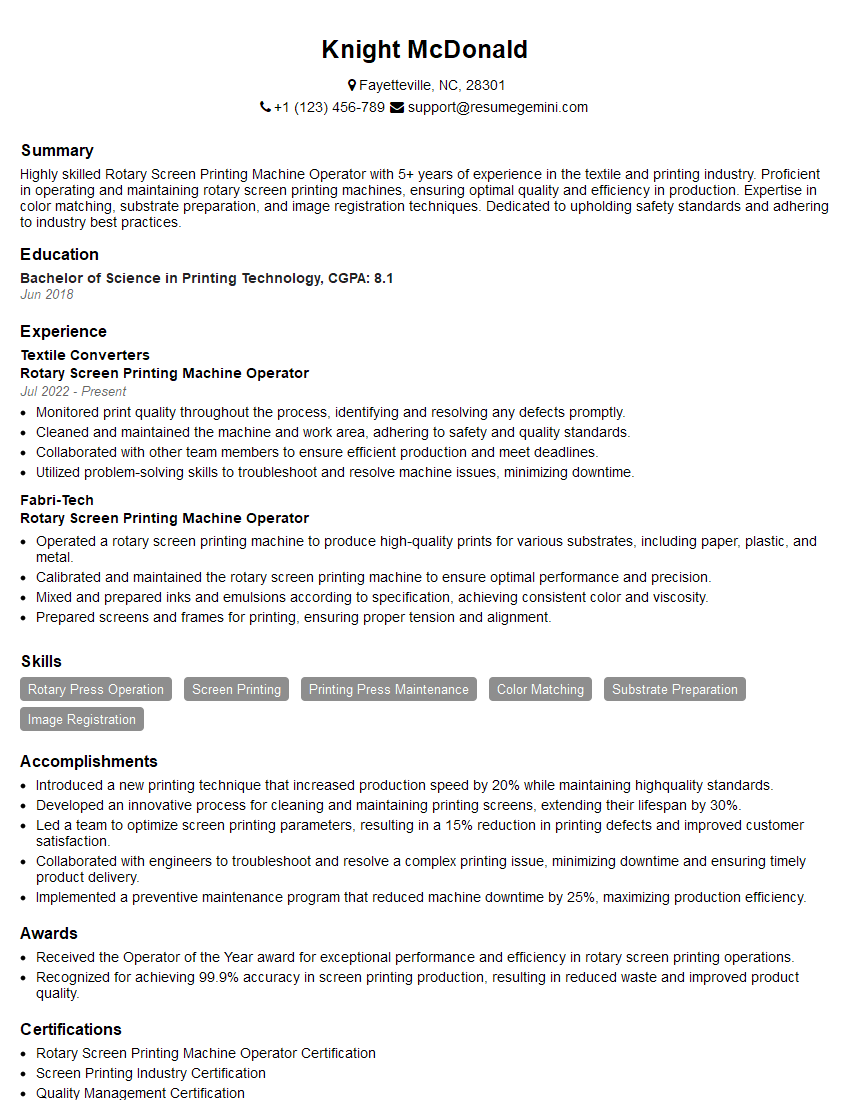

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Screen Printing Machine Operator

1. Explain the process of setting up a rotary screen printing machine for a new print job?

- Inspect the artwork and materials to ensure they meet specifications.

- Select the appropriate screen mesh and emulsion based on the design and substrate.

- Prepare the screens by coating them with emulsion, exposing them to UV light according to the design, and washing out the unexposed areas.

- Install the screens onto the machine and adjust their tension and alignment.

- Load the substrate (paper, fabric, etc.) onto the machine and adjust its feed and tension settings.

- Prepare the ink and adjust its viscosity, color, and other properties as required.

- Set up the machine’s operating parameters, including speed, temperature, and dwell time.

- Conduct a test print and make any necessary adjustments before proceeding with the production run.

2. How do you maintain and troubleshoot a rotary screen printing machine?

Maintenance

- Regularly clean the screens, machine parts, and work area to prevent ink buildup and contamination.

- Inspect and replace worn or damaged parts, such as squeegees, blankets, and belts, to ensure optimal performance.

- Lubricate moving parts according to the manufacturer’s instructions.

- Calibrate the machine’s sensors and controls to maintain accuracy and precision.

- Follow a preventive maintenance schedule to minimize downtime and extend the machine’s lifespan.

Troubleshooting

- Identify the source of the problem by observing the machine’s behavior and error messages.

- Refer to the machine’s manual or consult with a qualified technician for guidance.

- Check for common issues such as screen blockages, ink flow problems, or mechanical failures.

- Take appropriate corrective actions, such as cleaning, replacing parts, or adjusting settings.

- Document the troubleshooting process and any repairs made for future reference.

3. What are the different types of rotary screen printing machines and their applications?

- Flatbed rotary screen printing machines: Suitable for printing on flat substrates such as paper, cardboard, and textiles.

- Cylinder rotary screen printing machines: Designed for printing on cylindrical objects such as bottles, cans, and cups.

- Rotary offset screen printing machines: Utilize an offset blanket to transfer ink from the screen to the substrate, allowing for higher print quality and versatility.

- Digital rotary screen printing machines: Combine digital imaging technology with rotary screen printing, enabling variable data printing and customization.

- Semi-automatic and fully automatic rotary screen printing machines: Vary in their level of automation, from machines requiring manual loading and unloading to fully automated systems.

4. How do you ensure print quality and consistency on a rotary screen printing machine?

- Maintain proper screen tension and alignment to prevent image distortion and registration issues.

- Control ink viscosity and temperature to ensure consistent ink transfer and color matching.

- Use high-quality inks and substrates to achieve optimal print results.

- Regularly calibrate the machine’s sensors and controls to maintain accuracy and precision.

- Implement quality control procedures, such as regular inspections and test prints, to identify and correct any defects.

5. What are the safety precautions you observe when operating a rotary screen printing machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a mask.

- Keep the work area clean and organized to prevent tripping hazards and accidents.

- Securely fasten all machine guards and covers before operating.

- Never reach into the machine while it is running.

- Follow proper handling and storage procedures for inks and chemicals.

- Be aware of the machine’s emergency stop buttons and procedures.

6. How do you handle customer queries and feedback regarding print quality or other issues related to rotary screen printing?

- Listen attentively to the customer’s concerns and ask clarifying questions.

- Inspect the printed materials and identify the source of the problem.

- Communicate the findings to the customer in a clear and professional manner.

- Work with the customer to find a mutually acceptable solution.

- Document the issue and the resolution for future reference.

7. Describe your experience in using different types of inks and substrates in rotary screen printing.

- Experience with various ink types, including water-based, solvent-based, and UV-curable inks.

- Knowledge of different substrate materials, such as paper, cardboard, textiles, and plastics.

- Understanding of how different inks and substrates interact to achieve the desired print quality.

- Ability to adjust ink properties and machine settings to optimize print results for specific substrates.

- Experience in handling and storing inks and substrates safely and efficiently.

8. How do you stay updated with the latest advancements and best practices in rotary screen printing technology?

- Attend industry trade shows and conferences.

- Read technical journals and articles.

- Connect with other professionals in the field through online forums and social media.

- Seek training and certification programs from equipment manufacturers or industry organizations.

- Stay informed about new materials, inks, and printing techniques.

9. What are your strengths and weaknesses as a Rotary Screen Printing Machine Operator?

Strengths

- Proficient in operating and maintaining rotary screen printing machines.

- Strong understanding of printing principles and color matching.

- Excellent attention to detail and quality control.

- Ability to troubleshoot and resolve printing issues quickly and efficiently.

- Experience in working in a fast-paced, production environment.

Weaknesses

- Limited experience with digital rotary screen printing machines.

- Not familiar with all types of inks and substrates.

- Working extended hours or overtime can be challenging.

10. Why are you interested in this Rotary Screen Printing Machine Operator position?

- Passion for rotary screen printing and desire to contribute to the production of high-quality printed materials.

- Excited about the opportunity to learn from experienced professionals and expand my skills.

- Confident in my ability to make a positive impact on your team.

- Believe that my skills and experience align well with the requirements of the position.

- Eager to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Screen Printing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Screen Printing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rotary Screen Printing Machine Operator is entrusted with the proficient operation of high-speed rotary screen printing machines utilizing various substrates to produce high-quality printed materials. The role encompasses an intricate blend of technical expertise, dedication to quality, and a vigilant eye for detail.

1. Machine Operation

The core responsibility lies in skillfully operating the rotary screen printing machine, ensuring optimal performance, efficient production, and adherence to established print specifications. This includes:

- Setting up and calibrating the machine, optimizing print quality parameters

- Managing ink viscosity, color registration, and print alignment with precision

- Troubleshooting and resolving operational issues, maximizing machine uptime

2. Material Handling

Ensuring seamless material flow is paramount, involving:

- Loading and unloading substrates, handling different materials with care

- Monitoring print quality throughout the process, identifying and rectifying defects

- Maintaining a clean and organized work area, adhering to safety protocols

3. Quality Control

Maintaining the highest standards of print quality is non-negotiable, encompassing:

- Inspecting printed materials for defects, ensuring adherence to specifications

- Collaborating with quality control personnel to analyze and resolve issues

- Maintaining meticulous records of print runs and quality control checks

4. Maintenance and Troubleshooting

Ensuring machine longevity and efficiency requires:

- Performing routine maintenance tasks, such as cleaning, lubrication, and adjustments

- Identifying potential problems, taking proactive measures to prevent breakdowns

- Collaborating with maintenance technicians for repairs and complex troubleshooting

Interview Preparation Tips

Ace your Rotary Screen Printing Machine Operator interview with these expert tips:

1. Research the Company and Role

Spend ample time understanding the company’s values, mission, and the specific requirements of the role. This demonstrates your enthusiasm and genuine interest in the position.

- Visit the company website, read industry news, and consult company social media profiles

- Review the job description thoroughly, noting key responsibilities and qualifications

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to showcase your most relevant skills and experience. Emphasize your proficiency in rotary screen printing machine operation, quality control, and maintenance.

- Quantify your accomplishments with specific examples and metrics

- Use industry-specific terminology and demonstrate your technical knowledge

3. Practice Common Interview Questions

Prepare for common interview questions by rehearsing your answers. This will boost your confidence and enable you to articulate your qualifications effectively.

- Tell me about your experience operating rotary screen printing machines

- Describe your quality control process and how you ensure print quality

- How do you troubleshoot and resolve common printing issues?

4. Emphasize Safety and Attention to Detail

In this role, safety and attention to detail are paramount. Highlight your commitment to safety protocols and your meticulous approach to ensuring print quality.

- Share examples of how you prioritize safety in the workplace

- Explain your techniques for identifying and rectifying even minor printing defects

5. Follow Up and Seek Feedback

After the interview, send a brief thank-you note expressing your appreciation and reiterating your interest in the position. If possible, seek feedback on your performance to identify areas for improvement.

- Thank the interviewer for their time and consideration

- Reiterate your key qualifications and how they align with the role

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rotary Screen Printing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.