Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Screen Making Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Screen Making Technician so you can tailor your answers to impress potential employers.

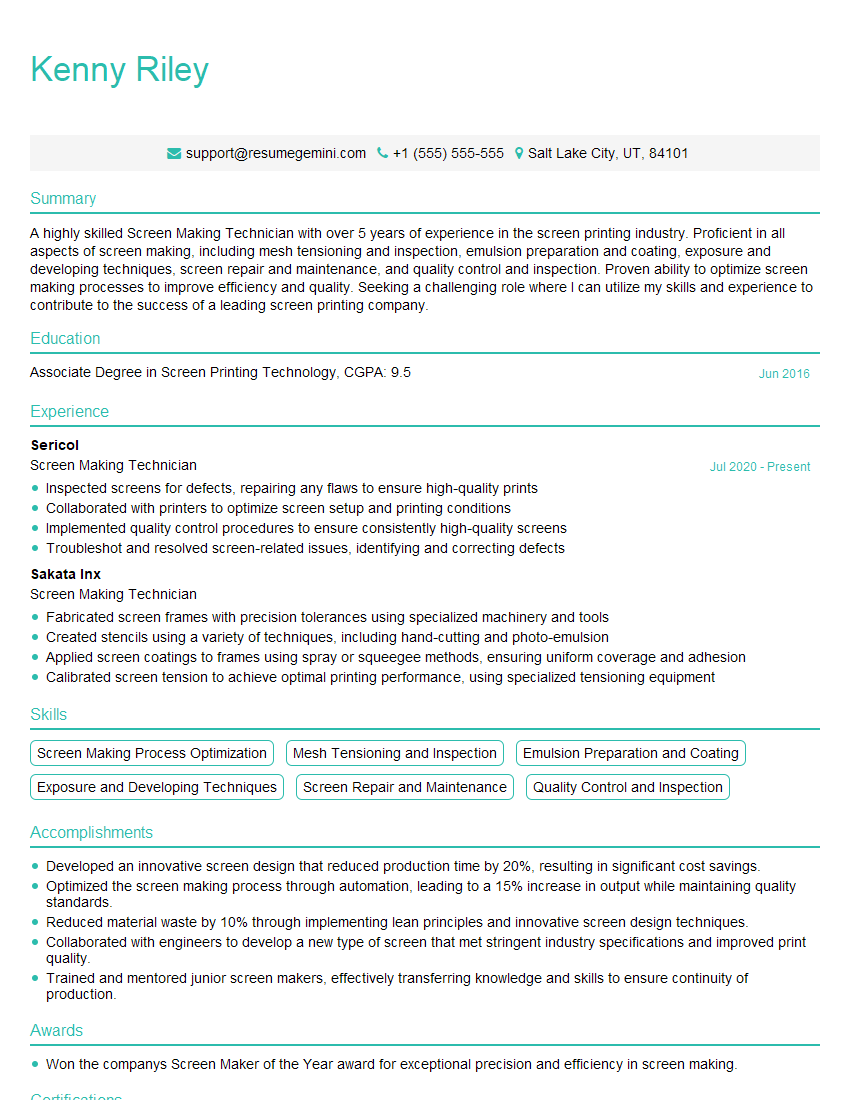

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screen Making Technician

1. What are the different types of screen printing inks?

- Plastisol inks are the most common type of screen printing ink. They are made from a PVC resin and are very durable and long-lasting.

- Water-based inks are another popular type of screen printing ink. They are made from a water-based acrylic resin and are less durable than plastisol inks, but they are also more environmentally friendly.

- UV-curable inks are a type of screen printing ink that is cured by exposure to ultraviolet light. They are very durable and resistant to chemicals and abrasion.

- Discharge inks are a type of screen printing ink that is used to create a distressed or vintage look. They are made from a bleach-based solution and are applied to the fabric before being cured.

2. What are the different types of screen printing presses?

Manual presses

- Manual presses are the most common type of screen printing press. They are operated by hand and are relatively inexpensive.

- Manual presses are best suited for small-scale printing projects.

Automatic presses

- Automatic presses are more expensive than manual presses, but they are also more efficient and can print larger quantities of garments.

- Automatic presses are best suited for large-scale printing projects.

3. What are the different types of screen printing screens?

- Wooden screens are the most common type of screen printing screen. They are made from a wooden frame and are covered with a mesh fabric.

- Metal screens are more durable than wooden screens and are often used for printing larger quantities of garments.

- Polyester screens are a type of screen printing screen that is made from a polyester fabric. They are very durable and can be used for a variety of printing applications.

4. What are the different types of screen printing squeegees?

- Wooden squeegees are the most common type of screen printing squeegee. They are made from a wooden handle and a rubber blade.

- Metal squeegees are more durable than wooden squeegees and are often used for printing larger quantities of garments.

- Plastic squeegees are a type of screen printing squeegee that is made from a plastic blade. They are very durable and can be used for a variety of printing applications.

5. What are the different types of screen printing emulsions?

- Diazo emulsions are the most common type of screen printing emulsion. They are made from a diazonium salt and are sensitive to UV light.

- Photopolymer emulsions are a type of screen printing emulsion that is made from a photopolymer resin. They are not sensitive to UV light and are instead cured by exposure to a light source.

6. What are the different steps involved in the screen printing process?

- Create a design

- Create a screen

- Apply emulsion to the screen

- Expose the screen to light

- Develop the screen

- Print the design

- Cure the print

7. What are some common problems that can occur during the screen printing process?

- Registration problems

- Ink bleeding

- Screen burn-out

- Ghosting

- Pinholes

8. How can you troubleshoot common problems that occur during the screen printing process?

- Registration problems can be caused by a number of factors, including misaligned screens, incorrect tension on the fabric, or a damaged screen.

- Ink bleeding can be caused by using too much ink, applying too much pressure to the squeegee, or using a screen that is not properly tensioned.

- Screen burn-out can be caused by exposing the screen to too much light or using a light source that is too strong.

- Ghosting can be caused by using a screen that has not been properly developed or by using a squeegee that is too soft.

- Pinholes can be caused by using a screen that has not been properly coated with emulsion or by using a squeegee that is too hard.

9. What are some tips for getting the best results from the screen printing process?

- Use high-quality materials

- Prepare your screens properly

- Use the correct amount of ink

- Apply the ink evenly

- Cure the prints properly

10. What are some new trends in the screen printing industry?

- Digital screen printing

- 3D screen printing

- Sustainable screen printing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screen Making Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screen Making Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Screen Making Technicians are responsible for making and maintaining screens used in the printing industry. They work with a variety of materials, including fabric, wire, and metal, and use specialized equipment to create screens that meet specific requirements.

1. Prepare the screen frame

The first step in making a screen is to prepare the frame. This involves cutting the frame to the desired size and shape, and then stretching the fabric over the frame and securing it with tacks or staples.

- Cut the frame to the desired size and shape.

- Stretch the fabric over the frame and secure it with tacks or staples.

2. Apply the emulsion

Once the frame is prepared, the next step is to apply the emulsion. Emulsion is a light-sensitive liquid that is applied to the fabric of the screen. When exposed to light, the emulsion hardens, creating a stencil that will allow ink to pass through in the desired areas.

- Apply the emulsion to the fabric of the screen.

- Expose the emulsion to light to harden it.

3. Develop the screen

Once the emulsion has been exposed to light, it is developed to remove the unexposed areas. This is done by washing the screen with water or a developer solution.

- Wash the screen with water or a developer solution.

- Rinse the screen and dry it.

4. Inspect the screen

Once the screen has been developed, it is inspected to ensure that it is free of defects. This involves looking for pinholes or other areas where the emulsion has not hardened properly.

- Inspect the screen for pinholes or other defects.

- Repair any defects that are found.

Interview Tips

Interviewing for a Screen Making Technician position can be a challenging but rewarding experience. Here are some tips to help you ace the interview and land the job.

1. Research the company

Before you go on an interview, it is important to do your research on the company. This will help you understand the company’s culture, values, and goals. You can find information about the company on their website, social media pages, and Glassdoor. You should also read any news articles or reviews about the company.

- Visit the company’s website and social media pages.

- Read news articles or reviews about the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Write out your answers to common interview questions.

- Practice your answers out loud in front of a mirror or with a friend.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Screen Making Technician. Be prepared to talk about your skills and knowledge, and how you have used them in previous jobs.

- List your skills and knowledge in a resume or portfolio.

- Prepare examples of how you have used your skills and knowledge in previous jobs.

4. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic and positive about their work. Show the interviewer that you are passionate about screen making and that you are excited about the opportunity to work for their company.

- Smile and make eye contact with the interviewer.

- Speak clearly and enthusiastically about your work.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Screen Making Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.