Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Screen Print Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

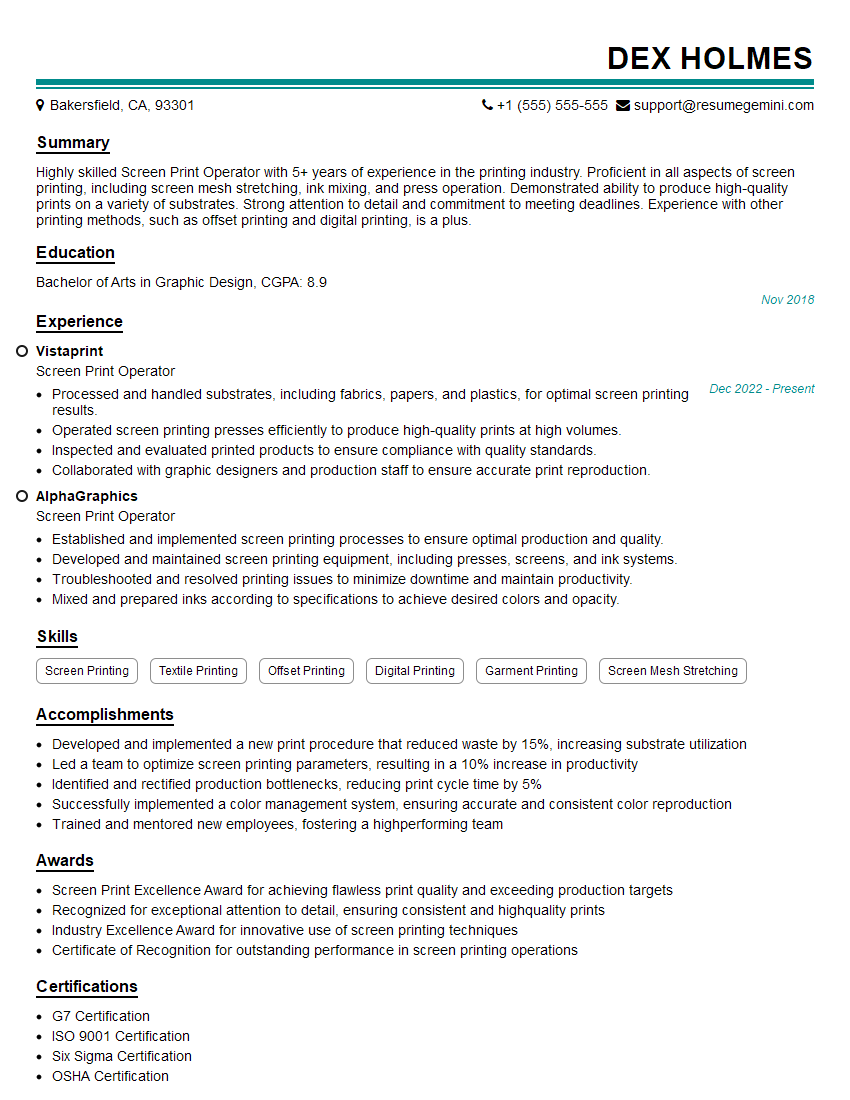

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screen Print Operator

1. Describe the process of preparing a screen for printing?

Preparing a screen for printing involves several steps:

- Degreasing the screen to remove any oils or contaminants.

- Applying a photosensitive emulsion to the screen and exposing it to UV light through a positive or negative film.

- Washing out the exposed emulsion, leaving the desired design open on the screen.

- Drying the screen and mounting it on the printing press.

2. How do you ensure the accuracy of registration when printing multiple colors?

Alignment Techniques:

- Using registration marks on the screen and artwork.

- Employing jigs or fixtures to align the screen precisely over the substrate.

Registration Equipment:

- Laser alignment systems for precise registration.

- Micrometers for measuring and adjusting registration.

3. What are the different types of meshes used in screen printing and how do they affect the print quality?

Mesh count refers to the number of threads per inch in the screen. Different mesh counts impact print quality:

- Higher mesh counts (e.g., 200-300 threads/inch) produce finer details and smoother prints.

- Lower mesh counts (e.g., 110-150 threads/inch) allow for thicker ink deposits and are suitable for coarse designs.

- Choosing the appropriate mesh count depends on the desired print effect, ink type, and substrate.

4. How do you troubleshoot common screen printing issues, such as misregistration, ink bleeding, or pinholes?

Troubleshooting common issues requires a systematic approach:

- Identify the specific issue and its potential causes.

- Check screen tension, emulsion exposure, ink viscosity, and press settings.

- Make adjustments to improve alignment, prevent ink bleeding, and eliminate pinholes.

- Maintain records of troubleshooting steps for future reference.

5. What is the role of ink viscosity in screen printing, and how do you adjust it?

Ink viscosity is crucial in screen printing:

- High viscosity inks require more pressure to push through the screen, resulting in thicker deposits.

- Low viscosity inks flow easily, reducing pressure requirements and producing thinner prints.

- Adjusting ink viscosity involves using additives or modifiers to achieve the desired consistency.

6. How do you maintain and clean screen printing equipment to ensure optimal performance?

Maintaining screen printing equipment includes:

- Regularly cleaning screens with solvents or degreasers to remove ink residues.

- Inspecting and replacing worn or damaged parts, such as squeegees and screens.

- Calibrating and maintaining press settings for accurate registration and print quality.

- Implementing a preventive maintenance schedule to minimize downtime.

7. Describe the different methods used to cure screen printed inks and their advantages and disadvantages.

Ink curing methods include:

- Advantages: Fast curing, durable prints, high gloss.

- Disadvantages: Requires specialized equipment, can damage some substrates.

- Advantages: Instant curing, low energy consumption.

- Disadvantages: Requires UV lamps, can fade over time.

- Advantages: No specialized equipment, cost-effective.

- Disadvantages: Slow curing, vulnerable to smudging.

Heat Curing:

UV Curing:

Air Drying:

8. What factors influence the choice of substrate for screen printing?

Substrate selection is based on several factors:

- Type of print design and desired effect.

- Compatibility with the printing ink and curing method.

- Surface texture, porosity, and dimensional stability.

- Cost, availability, and environmental considerations.

9. How do you ensure the safety of yourself and others in the screen printing environment?

Safety measures include:

- Wearing appropriate personal protective equipment (PPE), such as gloves, masks, and safety glasses.

- Proper ventilation to remove solvent fumes.

- Handling chemicals and inks according to their safety data sheets (SDS).

- Following established safety protocols and maintaining a clean workspace.

10. What are the latest trends and advancements in screen printing technology?

Recent advancements include:

- Digital screen printing for high-quality, variable data printing.

- Automated screen printing machines for increased efficiency and accuracy.

- Development of new inks and emulsions for specialized applications.

- Environmental initiatives to reduce waste and emissions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screen Print Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screen Print Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Screen Print Operator is responsible for the day-to-day operations of a screen printing machine. This includes preparing the machine, setting up the job, and monitoring the printing process to ensure quality and efficiency.

1. Machine Operation

Screen Print Operators are responsible for the safe and efficient operation of screen printing machines. This includes:

- Loading and unloading materials

- Adjusting machine settings

- Monitoring the printing process

- Troubleshooting and resolving issues

2. Job Setup

Screen Print Operators are also responsible for setting up print jobs. This includes:

- Creating and preparing screens

- Mixing and preparing inks

- Setting up the printing press

3. Quality Control

Screen Print Operators are responsible for ensuring the quality of printed products. This includes:

- Inspecting printed materials

- Identifying and correcting defects

- Maintaining quality control standards

4. Maintenance

Screen Print Operators are also responsible for basic maintenance of the screen printing machine. This includes:

- Cleaning and lubricating the machine

- Tightening bolts and screws

- Replacing worn or damaged parts

Interview Tips

Preparing well for an interview can increase your chances of making a positive impression. Here are some interview tips to help you ace your interview for a Screen Print Operator position:

1. Research the Company

Take some time to research the company you’re applying to. This will help you understand their business, their values, and their culture. It will also help you answer questions about the company during your interview.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during your interview. Some common interview questions you may be asked include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with screen printing?

3. Dress Professionally

First impressions matter. Dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also make sure your hair and nails are neat and tidy.

4. Be Punctual

Punctuality shows that you respect the interviewer’s time. Arrive for your interview on time, or even a few minutes early. This will show that you are organized and that you are serious about the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Screen Print Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!