Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Silk Screen Processor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Silk Screen Processor so you can tailor your answers to impress potential employers.

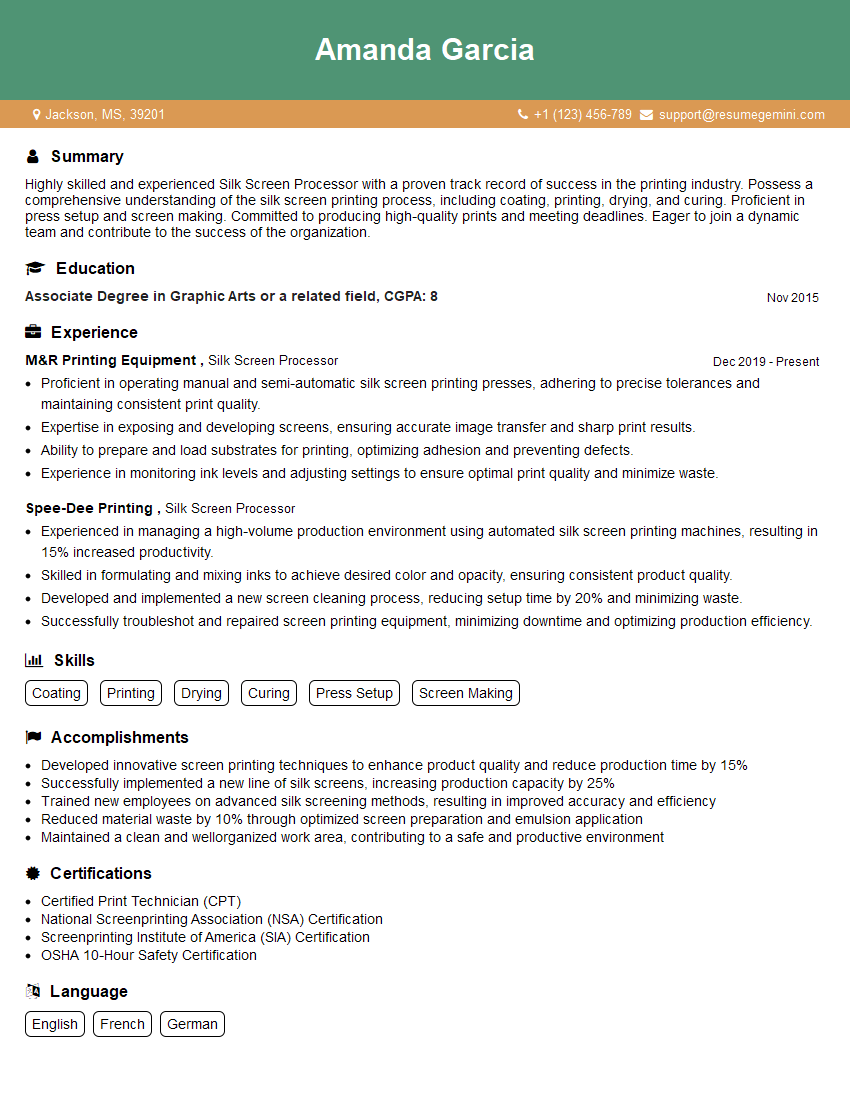

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Silk Screen Processor

1. What is the difference between a single-color and a multi-color screen printing process?

- Single-color screen printing involves using a single screen to print one color at a time, while multi-color screen printing uses multiple screens to print multiple colors in sequence.

- Multi-color screen printing requires careful alignment of the screens to ensure accurate color registration.

2. What factors affect the quality of a screen printed image?

Factors that affect the quality of the screen printed image

- The quality of the screen

- The type of ink used

- The mesh count of the screen

- The tension of the screen

- The exposure time of the screen

- The squeegee pressure

Measures to ensure quality

- Using high-quality screens and inks

- Selecting the appropriate mesh count for the desired image quality

- Properly tensioning the screen

- Optimizing the exposure time

- Applying the correct squeegee pressure

3. What are the different types of screens used in screen printing?

- Wood frames: Traditional and cost-effective, made of wood and covered with a mesh fabric.

- Metal frames: More durable and precise than wood frames, often used for high-volume printing.

- Vacuum frames: Hold the screen in place using a vacuum, providing a flat and stable printing surface.

- Stretcher bar frames: Lightweight and portable, made of aluminum or plastic, with adjustable tension.

4. What is the purpose of a squeegee in screen printing?

- Transfers ink through the screen onto the substrate

- Controls the amount of ink deposited

- Creates a smooth and even layer of ink

- Can be made of various materials (e.g., rubber, polyurethane) with different durometers (hardness)

5. How do you maintain and troubleshoot a screen printing machine?

- Regular cleaning: Remove ink residue and debris from screens, squeegees, and equipment

- Screen tension check: Ensure screens are properly tensioned for optimal printing results

- Alignment adjustment: Calibrate the machine to ensure accurate registration of screens and printing

- Troubleshooting: Identify and resolve issues such as ink bleeding, ghosting, or poor adhesion

6. What are the different types of inks used in screen printing?

- Plastisol inks: Durable, opaque, and heat-cured

- Water-based inks: Environmentally friendly, easy to clean up, but less durable

- Solvent-based inks: Vibrant colors, fast-drying, but require proper ventilation

- UV-curable inks: Cured using ultraviolet light, providing instant drying and high adhesion

7. What is the importance of proper screen exposure in screen printing?

- Defines the image: Exposure hardens the emulsion on the screen, creating the areas that will allow ink to pass through.

- Controls ink deposition: Proper exposure ensures that the hardened emulsion is sufficiently thick to prevent ink from bleeding or bridging.

- Maintains image quality: Accurate exposure minimizes distortion and ensures sharp and clear prints.

8. How do you handle and store screens to ensure their longevity?

- Proper storage: Store screens in a cool, dry place away from direct sunlight and moisture.

- Cleaning: Remove ink and emulsion residue promptly to prevent clogging and damage.

- Handling with care: Avoid bending or warping screens, and use protective covers when not in use.

- Re-tensioning: Re-tension screens regularly to maintain proper tension and prevent sagging.

9. What safety precautions should be taken when working with screen printing chemicals and equipment?

- Proper ventilation: Ensure adequate ventilation in the workspace to avoid exposure to harmful fumes.

- Protective gear: Wear gloves, masks, and protective clothing to prevent skin and eye irritation.

- Chemical handling: Follow manufacturer’s instructions for handling and storage of inks, solvents, and other chemicals.

- Equipment safety: Keep equipment properly maintained and use safety guards to prevent accidents.

10. Describe your experience in optimizing screen printing processes to improve efficiency and quality.

- Process optimization: Identified bottlenecks and implemented changes to streamline workflow and reduce production time.

- Quality control: Developed and implemented quality control measures to ensure consistent and high-quality prints.

- Equipment upgrades: Researched and recommended equipment upgrades to enhance efficiency and improve print quality.

- Training and development: Provided training to operators on best practices and process improvements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Silk Screen Processor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Silk Screen Processor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Silk Screen Processor is responsible for the production of high-quality printed materials using silk screen printing techniques. Their key responsibilities include:

1. Screen Preparation

Preparing silk screens by stretching, coating, and exposing them to create the desired printing image.

2. Ink Mixing and Printing

Mixing and preparing inks, and operating silk screen printing machines to apply ink to various substrates, such as paper, fabric, or metal.

3. Quality Control

Inspecting printed materials for defects and ensuring final products meet specifications and quality standards.

4. Equipment Maintenance

Maintaining and cleaning silk screen printing equipment, including presses, screens, and inks.

Interview Tips

To ace an interview for a Silk Screen Processor position, candidates should:

1. Research the Company and Industry

Familiarize yourself with the company’s website, mission, and industry trends. This demonstrates interest and enthusiasm for the role.

2. Highlight Relevant Experience and Skills

Emphasize your experience in silk screen printing, including specific techniques and equipment. Showcase your attention to detail and quality.

3. Prepare for Technical Questions

Expect questions about screen preparation, ink mixing, and printing processes. Provide detailed and clear explanations, supported by examples from your experience.

4. Practice Situational and Behavioral Questions

Prepare for questions that assess your problem-solving abilities, teamwork skills, and handling of challenges. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the role and industry, and arrive on time to demonstrate punctuality and respect.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Silk Screen Processor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.