Feeling lost in a sea of interview questions? Landed that dream interview for Strip Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Strip Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

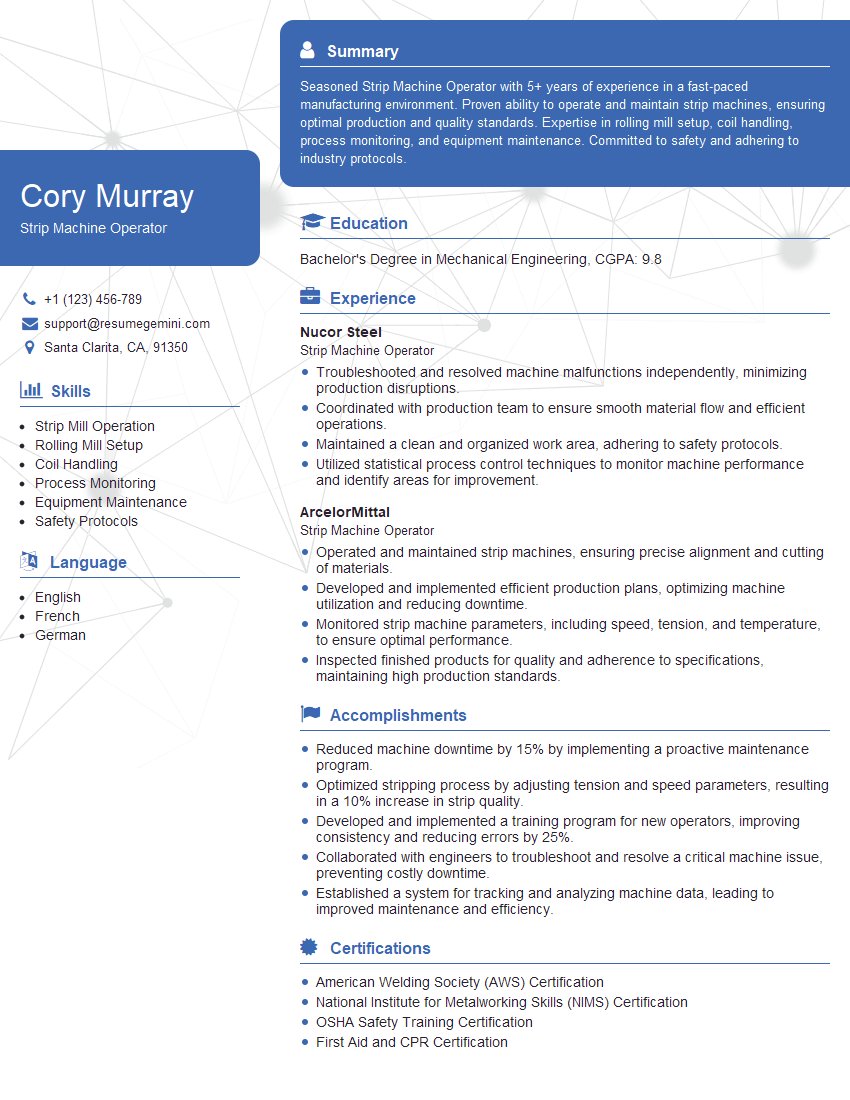

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Strip Machine Operator

1. What are the key responsibilities and duties of a Strip Machine Operator?

- Operate and maintain a stripping machine to remove insulation from wire and cable.

- Set up and adjust the machine to meet production requirements.

- Inspect and identify defective wire and cable.

- Maintain a clean and organized work area.

- Follow safety procedures and regulations.

2. What are the different types of stripping machines and their applications?

Types of stripping machines:

- Manual stripping machines

- Semi-automatic stripping machines

- Automatic stripping machines

- CNC stripping machines

Application of stripping machines:

- Removing insulation from wire and cable

- Cutting and crimping wire and cable

- Soldering and desoldering wire and cable

- Assembly and disassembly of electrical components

3. What are the safety precautions that should be taken when operating a stripping machine?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Keep hands and loose clothing away from moving parts.

- Never operate the machine when it is not properly guarded.

- Follow all lockout/tagout procedures before performing maintenance or repairs.

- Report any unsafe conditions or practices to a supervisor immediately.

4. How do you maintain and troubleshoot a stripping machine?

- Regularly clean and lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine for any signs of wear or damage.

- Troubleshoot common problems, such as:

- Machine not starting

- Machine not cutting properly

- Machine not stripping insulation cleanly

- If you are unable to troubleshoot the problem, contact a qualified technician.

5. What are the quality control procedures that should be followed when operating a stripping machine?

- Inspect the wire and cable before stripping to ensure that it is free of defects.

- Set up and adjust the machine according to the manufacturer’s specifications.

- Monitor the stripping process to ensure that the insulation is being removed cleanly and evenly.

- Inspect the stripped wire and cable to ensure that it meets the required specifications.

- Keep records of all quality control checks.

6. What are the different types of wire and cable that can be stripped using a stripping machine?

- Solid wire

- Stranded wire

- Coaxial cable

- Ribbon cable

- Flat cable

7. What are the different types of insulation that can be removed using a stripping machine?

- PVC

- PE

- XLPE

- Nylon

- Teflon

8. What are the advantages and disadvantages of using a stripping machine?

Advantages:

- Increased production speed

- Improved accuracy and consistency

- Reduced labor costs

- Improved safety

Disadvantages:

- High initial investment cost

- Requires skilled operators

- Can be noisy and generate dust

9. What are the latest trends in stripping machine technology?

- Increased use of automation

- Development of more user-friendly machines

- Integration of new technologies, such as vision systems and lasers

- Development of more sustainable machines

10. What are your career goals and how does this position fit into them?

- I am passionate about the manufacturing industry and I am eager to learn more about the different processes and technologies involved.

- I am a hard worker and I am always willing to go the extra mile.

- I am confident that I have the skills and experience necessary to be successful in this position.

- I am excited about the opportunity to contribute to the company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Strip Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Strip Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Strip Machine Operators are responsible for the efficient operation of strip machines, which cut and shape metal into strips. They work in a variety of industries, including automotive, aerospace, and construction.

1. Set up and operate strip machines

Strip Machine Operators set up and operate strip machines according to the specifications of the job. They adjust the machine’s settings, such as the speed, feed rate, and blade tension, to ensure that the machine produces the desired results.

- Load coils of metal into the machine

- Adjust the machine’s settings

- Start and stop the machine

2. Monitor the machine’s operation

Strip Machine Operators monitor the machine’s operation to ensure that it is running smoothly and producing the desired results. They check the machine’s gauges and dials to monitor the machine’s speed, feed rate, and blade tension.

- Check the machine’s gauges and dials

- Listen for any unusual noises or vibrations

- Make adjustments to the machine’s settings as needed

3. Inspect the finished product

Strip Machine Operators inspect the finished product to ensure that it meets the specifications of the job. They check the product for defects, such as scratches, dents, or tears.

- Visually inspect the finished product

- Measure the product to ensure that it meets the specifications of the job

- Reject any products that do not meet the specifications of the job

4. Maintain the machine

Strip Machine Operators maintain the machine to ensure that it is in good working order. They clean the machine, lubricate the moving parts, and replace worn parts.

- Clean the machine

- Lubricate the moving parts

- Replace worn parts

Interview Tips

Preparing for an interview for a Strip Machine Operator position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Before you go to your interview, it is important to research the company and the position. This will help you understand what the company is looking for and how your skills and experience match the requirements of the job.

- Visit the company’s website to learn more about their products, services, and culture.

- Read online reviews of the company to get a sense of what it is like to work there.

- Talk to people in your network who work for the company or who have worked there in the past.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked during an interview for a Strip Machine Operator position. It is important to practice answering these questions so that you can deliver clear and concise answers.

- Tell me about your experience operating strip machines.

- What are your strengths and weaknesses as a Strip Machine Operator?

- How do you handle working under pressure?

3. Be prepared to talk about your safety experience

Safety is a critical aspect of operating strip machines. During your interview, you will likely be asked about your safety experience and how you would handle potential hazards.

- Describe your experience with lockout/tagout procedures.

- What are some of the common hazards associated with operating strip machines?

- How would you handle a situation where a strip machine malfunctioned?

4. Be enthusiastic and professional

First impressions matter, so it is important to be enthusiastic and professional during your interview. Dress appropriately, arrive on time, and be prepared to answer questions about your experience and qualifications.

- Dress in business casual attire.

- Arrive on time for your interview.

- Be prepared to answer questions about your experience and qualifications.

Next Step:

Now that you’re armed with the knowledge of Strip Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Strip Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini