Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fur Glazing and Polishing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

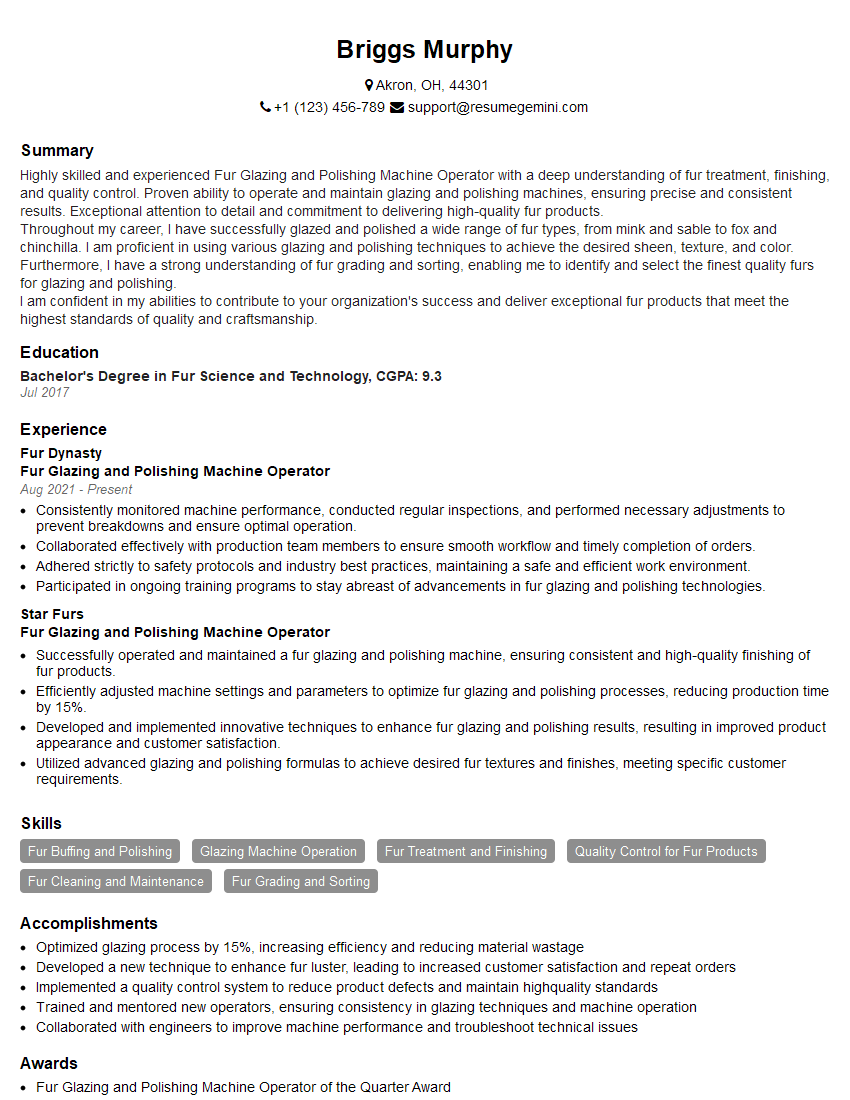

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fur Glazing and Polishing Machine Operator

1. Describe the process of glazing and polishing fur?

The glazing and polishing process involves several key steps:

- Preparation: Fur is first cleaned and degreased to remove any dirt or oils.

- Glazing: A glazing agent, typically a gelatinous substance, is applied to the fur to create a smooth and glossy surface.

- Drying: The glazed fur is allowed to dry thoroughly to set the glaze.

- Polishing: Using a buffing wheel or brush, the glazed fur is polished to achieve a high shine and remove any loose fibers.

2. What are the different types of glazing agents used in fur processing?

Liquid Glazing Agents

- Gelatin

- Casein

- Polyvinyl alcohol

Solid Glazing Agents

- Gum arabic

- Tragacanth

- Shellac

Emulsion Glazing Agents

- Oil-in-water emulsions

- Water-in-oil emulsions

3. How do you determine the appropriate glazing agent and concentration for a particular fur type?

- Fur Type: Different fur types, such as beaver, mink, or fox, have varying absorption and adhesion properties, requiring specific glazing agents.

- Desired Effect: The intended glossiness and stiffness of the finished product influence the choice of agent and concentration.

- Environmental Factors: Humidity and temperature can affect the drying and polishing process, so considerations must be made.

- Experience and Experimentation: Trial and error, combined with knowledge of different fur types and glazing agents, is essential.

4. What are the common defects that can occur during glazing and polishing?

- Glaze Cracking: Occurs when the glazed film is too thick or applied unevenly.

- Glaze Peeling: Caused by insufficient adhesion between the glaze and the fur.

- Fur Stiffening: Excessive glazing can make the fur stiff and unnatural.

- Burnishing: Over-polishing can damage the fur and result in a dull appearance.

- Color Fading: Improper chemical use or exposure to sunlight can cause fur discoloration.

5. How do you ensure the quality of the glazed and polished fur?

- Inspection: Regularly inspect fur during and after processing to identify any defects promptly.

- Testing: Conduct tests on sample fur to determine glaze adhesion, gloss, and durability.

- Monitoring Process Parameters: Control temperature, humidity, and application rates to maintain consistent quality.

- Training and Supervision: Provide proper training to operators and supervise their work to ensure adherence to standards.

6. What are the safety precautions that should be taken when operating glazing and polishing machines?

- Wear Protective Gear: Gloves, eye protection, and a respirator are essential to prevent exposure to chemicals and dust.

- Proper Ventilation: Ensure adequate ventilation to exhaust fumes and dust generated during the process.

- Machine Guarding: All moving parts of the machines should be properly guarded to prevent accidents.

- Electrical Safety: Follow proper electrical wiring and grounding practices to prevent electrical hazards.

- Training and Supervision: Operators should receive thorough training on safety procedures and be supervised to maintain safety standards.

7. Describe the maintenance and cleaning procedures for glazing and polishing machines.

Regular maintenance and cleaning are crucial for optimal machine performance and safety:

- Daily Cleaning: Remove fur residue, dust, and glazing agents from the machines using brushes, compressed air, and cleaning solutions.

- Weekly Inspection: Check for wear or damage to brushes, wheels, and other components. Lubricate moving parts as needed.

- Monthly Maintenance: Conduct thorough cleaning and inspection of all machine parts. Calibrate sensors and adjust settings if necessary.

- Annual Overhaul: Perform a comprehensive inspection and repair or replace worn or damaged components to ensure peak performance.

8. What troubleshooting steps would you take if the glazing or polishing process is not producing satisfactory results?

- Check Machine Settings: Verify if settings for temperature, speed, and pressure are optimal for the fur type and desired results.

- Inspect Raw Material: Ensure that the fur is properly cleaned and degreased before glazing and polishing.

- Examine Glazing Agent: Check the concentration and application of the glazing agent. Adjust as necessary to achieve the desired effect.

- Test Machine Components: Inspect brushes, wheels, and other parts for wear or damage that could affect performance.

- Review Process Parameters: Re-evaluate the drying and polishing time and temperature to ensure they are appropriate for the fur type.

9. How do you stay updated on the latest advancements in fur glazing and polishing techniques?

- Industry Conferences and Exhibitions: Attend industry events to learn about new technologies, products, and best practices.

- Trade Publications and Journals: Subscribe to relevant publications to stay informed about advancements in the field.

- Online Resources: Utilize reputable websites and forums to access technical articles and research findings.

- Networking and Collaboration: Connect with professionals in the industry to exchange knowledge and insights.

- Continuing Education: Participate in workshops or training programs to enhance skills and stay up-to-date with industry standards.

10. What are your career aspirations in the field of fur processing?

My career aspirations within the field of fur processing are to:

- Enhance my Technical Skills: Continuously seek opportunities to improve my understanding of glazing and polishing techniques, as well as the properties of different fur types.

- Supervisory and Management Roles: Advance to supervisory or management positions, where I can lead and motivate teams to achieve high-quality results.

- Innovation and Development: Contribute to the research and development of new glazing and polishing methods that enhance the quality and sustainability of fur products.

- Industry Expertise: Become recognized as an expert in fur glazing and polishing, sharing my knowledge through mentorship and technical presentations.

- Environmental Stewardship: Promote environmentally responsible practices within the fur processing industry, ensuring the sustainability of natural resources.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fur Glazing and Polishing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fur Glazing and Polishing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fur Glazing and Polishing Machine Operators are responsible for operating and maintaining glazing and polishing machines to produce a variety of fur products. These machines apply a protective coating to the fur, which gives it a glossy finish and helps to prevent it from becoming damaged. Machine operators must be able to adjust the machine settings and ensure that the fur is properly treated. They also need to be able to identify and correct any problems that may occur during the glazing and polishing process.

1. Machine Operation

Operate and maintain glazing and polishing machines to apply a protective coating to fur products.

- Adjust machine settings to ensure proper treatment of fur.

- Monitor the glazing and polishing process to identify and correct any problems.

2. Product Inspection

Inspect finished fur products to ensure that they meet quality standards.

- Check for defects in the glazing and polishing finish.

- Identify any areas that need to be reworked.

3. Machine Maintenance

Perform routine maintenance on glazing and polishing machines to ensure optimal performance.

- Clean and lubricate machine components.

- Replace worn or damaged parts.

4. Safety and Compliance

Follow all safety regulations and procedures.

- Wear appropriate personal protective equipment.

- Maintain a clean and safe work area.

Interview Tips

Preparing for an interview can be daunting, but there are some simple steps you can take to increase your chances of success. Here are a few tips to help you ace your interview for a Fur Glazing and Polishing Machine Operator position:

1. Research the Company

Take some time to learn about the company you’re applying to. This will show the interviewer that you’re interested in the position and that you’ve taken the time to learn about their company culture.

- Visit the company website.

- Read the company’s social media pages.

- Talk to people who work at the company.

2. Practice Your Answers

Once you’ve researched the company, take some time to practice answering common interview questions. This will help you feel more confident and prepared during your interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This doesn’t mean you have to wear a suit, but you should choose clothes that are clean, pressed, and appropriate for the job you’re applying for.

- Choose clothes that are comfortable and allow you to move freely.

- Avoid wearing clothes that are too revealing or too casual.

- Make sure your clothes are clean and pressed.

4. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and authentic, and let your personality shine through.

- Be confident in your abilities.

- Be enthusiastic about the position.

- Be yourself and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fur Glazing and Polishing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!