Are you gearing up for a career in Operating Engineer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Operating Engineer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

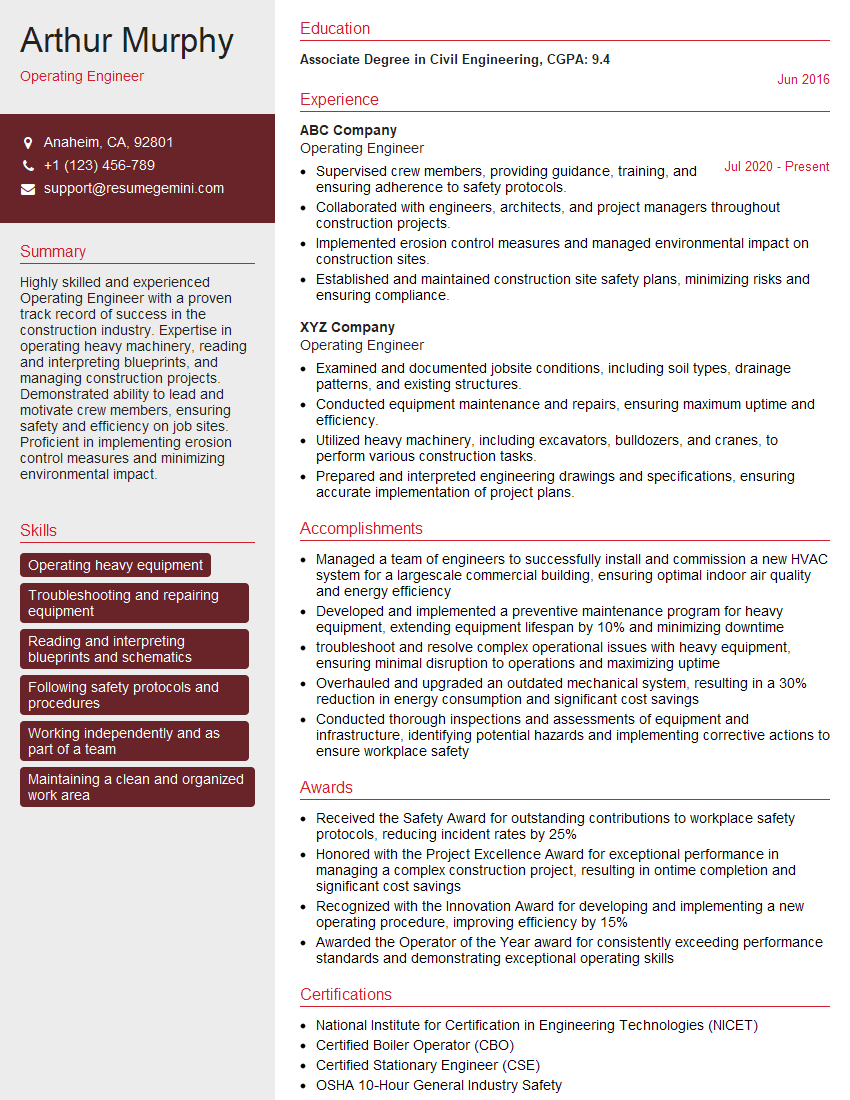

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Operating Engineer

1. What are the key responsibilities of an Operating Engineer?

As an experienced Operating Engineer, I am adept at:

- Operating and maintaining heavy equipment, including cranes, excavators, bulldozers, and graders

- Interpreting blueprints and engineering drawings to ensure proper equipment operation

- Performing routine maintenance and repairs on equipment to ensure optimal performance

- Troubleshooting and resolving technical issues with equipment and machinery

- Collaborating with other team members to coordinate work activities and ensure project success

2. Describe your experience with different types of heavy equipment.

Cranes

- Extensive experience operating hydraulic and lattice boom cranes

- Certified crane operator with a proven track record of safe and efficient crane operations

- Proficient in performing load calculations, rigging, and crane setup

- Thorough understanding of crane capacities, limitations, and safety protocols

Excavators

- Skilled in operating various sizes and types of excavators

- Experienced in trenching, digging, backfilling, and grading operations

- Proficient in using hydraulic attachments, such as buckets, augers, and rock breakers

- Strong understanding of soil mechanics and excavation techniques

3. What are the safety precautions you take when operating heavy equipment?

Safety is paramount in my work. I adhere to the following safety precautions:

- Performing thorough pre-operational inspections to ensure equipment is in safe working condition

- Wearing appropriate personal protective equipment (PPE), such as hard hats, safety glasses, and gloves

- Maintaining a clean and organized work area to minimize hazards

- Following established safety protocols and industry best practices

- Communicating with colleagues and supervisors to coordinate work activities and mitigate risks

- Participating in regular safety training and refresher courses to stay up-to-date on industry standards

4. How do you stay updated on the latest advancements in heavy equipment technology?

I am committed to continuous learning and professional development. To stay abreast of advancements in heavy equipment technology, I actively engage in the following:

- Attending industry conferences, seminars, and workshops

- Reading trade publications and technical journals

- Consulting with equipment manufacturers and industry experts

- Participating in online forums and discussion groups

- Seeking opportunities for hands-on experience with new technologies

5. Describe a challenging project you worked on as an Operating Engineer and how you overcame the challenges.

During the construction of a high-rise building in a densely populated urban area, our team encountered unexpected soil conditions that made excavation challenging. To overcome this obstacle, I proposed a modified excavation plan that involved:

- Using a combination of sheet piling and soil nailing to stabilize the excavation walls

- Implementing a phased excavation approach to minimize the risk of soil collapse

- Working closely with structural engineers to design a support system for the adjacent buildings

- Continuously monitoring soil movement and adjusting the excavation plan as needed

Through careful planning and collaboration, we successfully completed the excavation without any safety incidents or damage to the surrounding structures.

6. How do you prioritize tasks and manage multiple projects simultaneously?

Effectively prioritizing tasks and managing multiple projects requires:

- Creating a clear to-do list and breaking down large tasks into smaller, manageable ones

- Assessing the importance and urgency of each task

- Setting realistic deadlines and allocating resources accordingly

- Delegating tasks to team members when appropriate

- Communicating regularly with supervisors and stakeholders to keep them informed of progress

- Using project management software or tools to track progress and stay organized

7. How do you handle working in a team environment?

As an Operating Engineer, collaboration and teamwork are crucial. I am highly effective in:

- Communicating clearly and concisely with team members

- Cooperating with colleagues to achieve common goals

- Supporting and assisting other team members when needed

- Resolving conflicts respectfully and professionally

- Maintaining a positive and collaborative work environment

- Recognizing and appreciating the contributions of others

8. How do you ensure that the equipment you operate is in top working condition?

Maintaining equipment in top working condition is essential for safety, efficiency, and productivity. I prioritize the following practices:

- Performing regular inspections to identify potential issues early on

- Conducting routine maintenance, such as changing fluids, filters, and spark plugs

- Making minor repairs and adjustments as needed

- Reporting any significant problems or concerns to my supervisor promptly

- Keeping equipment clean and organized, which helps extend its lifespan

- Seeking training on new equipment maintenance techniques and technologies

9. What are your strengths and weaknesses as an Operating Engineer?

Strengths

- Highly skilled in operating and maintaining heavy equipment

- Excellent problem-solving and troubleshooting abilities

- Strong attention to detail and safety consciousness

- Effective communication and teamwork skills

- Adaptable and eager to learn new technologies

Weaknesses

- I tend to be a perfectionist, which can sometimes lead to spending more time on tasks than necessary

- I am relatively new to the industry, but I am actively seeking opportunities to gain more experience

10. Why are you interested in working for our company?

I am drawn to your company’s reputation for excellence in the construction industry. Your commitment to safety, innovation, and customer satisfaction aligns perfectly with my own values and career aspirations. Moreover, I am particularly impressed with your company’s focus on employee development and training. I believe that working for your company would provide me with the opportunity to enhance my skills, contribute to meaningful projects, and build a successful career.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Operating Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Operating Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Operating Engineer holds a crucial role in maintaining, operating, and repairing various types of machinery and equipment in various industries.

1. Operating and Maintaining Machinery

Operating Engineers are responsible for ensuring that machinery and equipment are in optimal working condition. Their duties include starting, stopping, and monitoring equipment performance, as well as conducting routine maintenance tasks.

- Inspecting machinery and equipment for potential issues

- Performing routine maintenance tasks, such as cleaning, lubrication, and minor repairs

2. Troubleshooting and Repairing Equipment

When equipment malfunctions or breaks down, Operating Engineers diagnose the problem and perform the necessary repairs. They use their knowledge of mechanical systems and electrical components to identify and fix issues efficiently.

- Troubleshooting equipment malfunctions and identifying the root cause

- Performing repairs, such as replacing parts, adjusting settings, or recalibrating systems

3. Monitoring and Controlling Processes

Operating Engineers often work in industrial settings where they monitor and control various processes. They ensure that equipment operates within safe and efficient parameters, and they respond to changes in conditions or emergencies.

- Monitoring process parameters, such as temperature, pressure, and flow rates

- Adjusting controls and settings to maintain optimal process conditions

4. Safety and Compliance

Operating Engineers prioritize safety and compliance in all their operations. They adhere to established safety protocols, wear appropriate protective gear, and follow industry regulations.

- Ensuring that equipment is operated safely and in compliance with regulations

- Following established safety protocols and using proper protective gear

Interview Tips

Preparing thoroughly for an Operating Engineer interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and the Role

Before the interview, take the time to research the company you’re applying to and the specific role you’re interviewing for. This will help you understand the company’s culture, values, and the expectations for the position.

- Visit the company’s website to learn about their mission, products or services, and recent news.

- Read job descriptions carefully to identify the key responsibilities and qualifications required for the role.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers accordingly. Practice delivering your responses clearly and concisely.

- Prepare answers to questions about your experience, skills, and why you’re interested in the position.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Highlight Your Technical Skills

Operating Engineers require a strong foundation in technical skills. Be prepared to discuss your knowledge of mechanical systems, electrical components, and troubleshooting techniques.

- Mention any certifications or training you have that demonstrate your technical expertise.

- Provide examples of projects or experiences where you applied your technical skills to solve problems or improve efficiency.

4. Emphasize Your Safety Mindset

Safety is paramount for Operating Engineers. Highlight your commitment to following safety protocols, using proper protective gear, and ensuring equipment is operated safely.

- Describe your understanding of safety regulations and your experience in adhering to them.

- Provide examples of how you have prioritized safety in your previous roles.

5. Be Enthusiastic and Confident

Show your enthusiasm for the role and the industry. Demonstrate your confidence in your abilities and your eagerness to learn and grow.

- Express your interest in the company and the position, and explain why you believe you’re a suitable candidate.

- Maintain a positive attitude throughout the interview and ask thoughtful questions to show your engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Operating Engineer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.