Are you gearing up for a career in Armhole Presser? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Armhole Presser and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

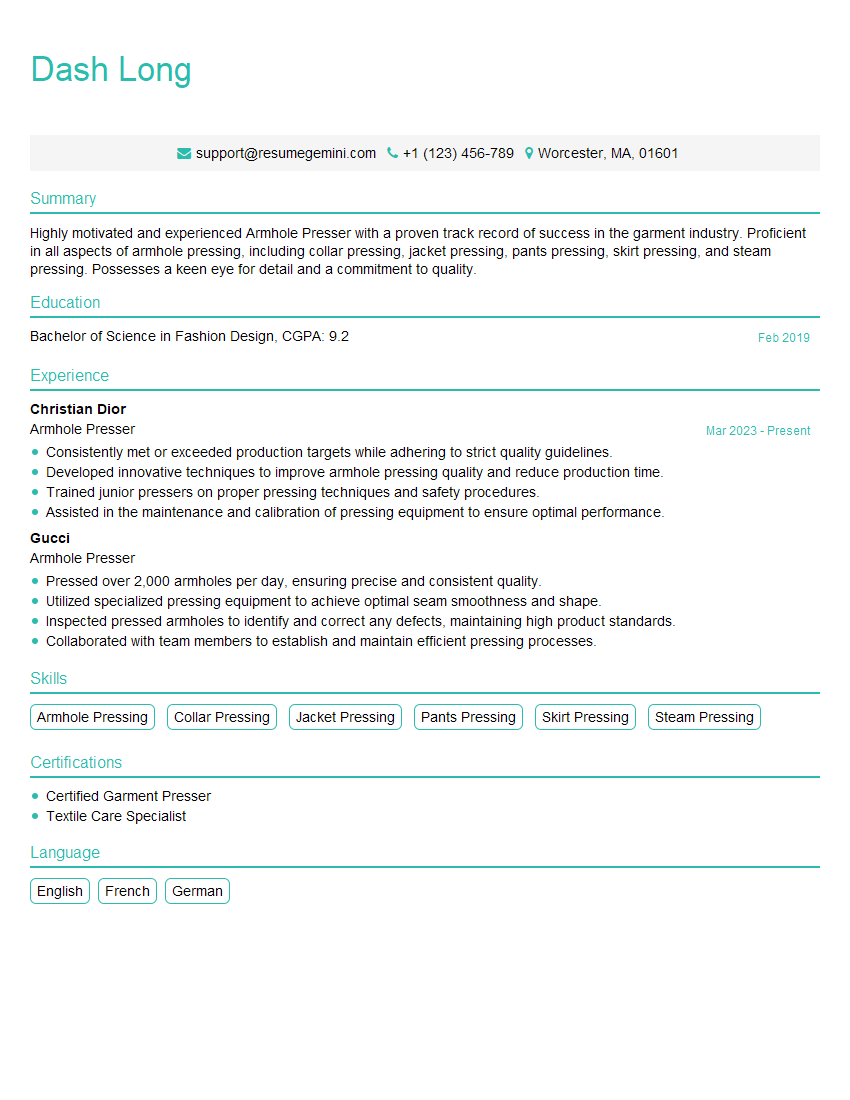

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Armhole Presser

1. Explain the importance of seam allowance in pressing armholes?

- Seam allowance helps to prevent fraying and unraveling of the fabric.

- It also provides a guide for precise stitching, ensuring the armhole is evenly pressed and symmetrical.

- Proper seam allowance ensures the armhole fits the garment correctly and provides a clean, professional finish.

2. Describe the different types of presser feet used for armhole pressing.

- Sleeve Roll Presser Foot: For curved areas like armholes, provides a smooth, even finish.

- Tailor’s Ham Presser Foot: Designed to press darts, curves, and small details, including armholes.

- Cording Presser Foot: Used for pressing cording or piping into armholes, providing a clean and professional look.

3. Explain the process of pressing an armhole using a sleeve roll presser foot.

Pre-Treatment:

- Trim and notch the seam allowance.

- Apply starch or moisture to the fabric to enhance the pressing results.

Pressing:

- Attach the sleeve roll presser foot to the sewing machine.

- Set the appropriate heat and steam settings for the fabric.

- Gently insert the armhole curve into the presser foot, rolling the fabric away as you press.

- Repeat until the entire armhole is pressed smoothly and evenly.

4. How do you determine the ideal pressing temperature and time for different fabrics?

- Refer to the garment label or fabric care guide.

- Test a small, inconspicuous area of the fabric to ensure the temperature and time are not too high.

- Start with a lower temperature and gradually increase it until the desired results are achieved.

- Consider the fabric’s composition, thickness, and texture.

5. Explain how to avoid pressing marks or imprints on delicate fabrics.

- Use a pressing cloth or parchment paper between the fabric and the iron.

- Set the iron to a lower temperature.

- Press with a light touch and avoid applying excessive pressure.

- Test the fabric in an inconspicuous area to determine the appropriate settings.

6. How do you handle challenging armholes, such as those with gathers or unusual shapes?

- Gathered Armholes: Press the seam allowance away from the gathers, then carefully press the gathers themselves using a fine point on the iron or a gathering presser foot.

- Unusual Shapes: Use a combination of presser feet and pressing techniques to accommodate the unique shape, such as a sleeve roll presser foot for curves and a tailor’s ham for darts.

7. What are some common mistakes to avoid when pressing armholes?

- Overpressing, which can damage or discolor the fabric.

- Not pressing the seam allowance properly, which can lead to fraying and uneven edges.

- Using the wrong presser foot, which can cause puckering or uneven pressing.

- Not testing the fabric before pressing, which can result in damage.

8. How do you ensure the armholes are pressed symmetrically?

- Use a template or guide to mark the armhole curves before pressing.

- Press one armhole at a time and compare it to the other for symmetry.

- Fold the garment along the center front or back to check if the armholes match.

9. Explain how you optimize the quality of your armhole pressing.

- Use a high-quality iron and presser feet.

- Maintain the cleanliness of the iron and its components.

- Practice regularly to improve technique and precision.

- Seek feedback from supervisors or experienced colleagues to enhance skills.

10. Describe a situation where you encountered a challenging armhole pressing task and how you overcame the difficulties.

- Explain the specific garment and armhole design.

- Describe the techniques and tools you employed to press the armholes effectively.

- Highlight any obstacles encountered and how you resolved them.

- Emphasize the positive outcome and the skills you demonstrated.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Armhole Presser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Armhole Presser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Armhole Presser is a skilled professional who plays a crucial role in the clothing manufacturing process. Their primary responsibility is to ensure the smooth and precise pressing of armholes, a vital step in shaping and finishing garments.

1. Pressing and Finishing Armholes

The Armhole Presser operates specialized pressing equipment to press and shape the armholes of various garments. They use heat and moisture to achieve the desired crease and shape, ensuring the armholes maintain their form and fit throughout the garment’s use.

2. Maintaining Equipment

To ensure optimal performance and safety, the Armhole Presser is responsible for maintaining and cleaning pressing equipment, including checking for any malfunctions or damages that require attention. They ensure that the equipment is calibrated and functioning correctly to achieve the best possible results.

3. Quality Control

The Armhole Presser plays a key role in quality control by inspecting pressed armholes for any defects or inconsistencies. They identify and correct any issues to ensure that garments meet the required standards of quality and appearance.

4. Teamwork and Communication

Armhole Pressers work closely with other members of the production team, including other pressers, sewers, and supervisors. They communicate effectively to coordinate work schedules, adhere to production deadlines, and ensure seamless workflow.

Interview Tips

To ace an interview for an Armhole Presser position, follow these tips and preparation hacks:

1. Research the Company and Role

Before the interview, take time to research the company’s profile, values, and specific requirements for the Armhole Presser role. This will demonstrate your interest, enthusiasm, and attention to detail.

2. Emphasize Skills and Experience

Highlight your technical skills in garment pressing and armhole shaping. Quantify your experience and provide specific examples of your accomplishments, such as the number of garments pressed or the quality standards you achieved.

- Example: “In my previous role, I pressed an average of 300 garments per day, ensuring consistent and precise armhole shaping that met the company’s quality standards.”

3. Showcase Quality Control

Emphasize your attention to detail and commitment to quality control. Share instances where you identified and corrected defects, which will demonstrate your proactive approach and dedication to delivering exceptional results.

- Example: “I once identified slight inconsistencies in the shape of pressed armholes. I promptly reported the issue to my supervisor and worked with the sewing team to adjust their techniques, ensuring that all subsequent garments met the desired specifications.”

4. Highlight Teamwork and Communication

Accentuate your ability to work effectively in a team environment and communicate clearly. Share examples of how you coordinated with other pressers or production staff to complete projects efficiently.

- Example: “I worked closely with the sewing team to understand their specific requirements for armhole shaping. This allowed me to tailor my pressing techniques to meet their expectations and ensure the final garments met the desired fit and appearance.”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Armhole Presser role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.