Feeling lost in a sea of interview questions? Landed that dream interview for Buffing Wheel Presser but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Buffing Wheel Presser interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

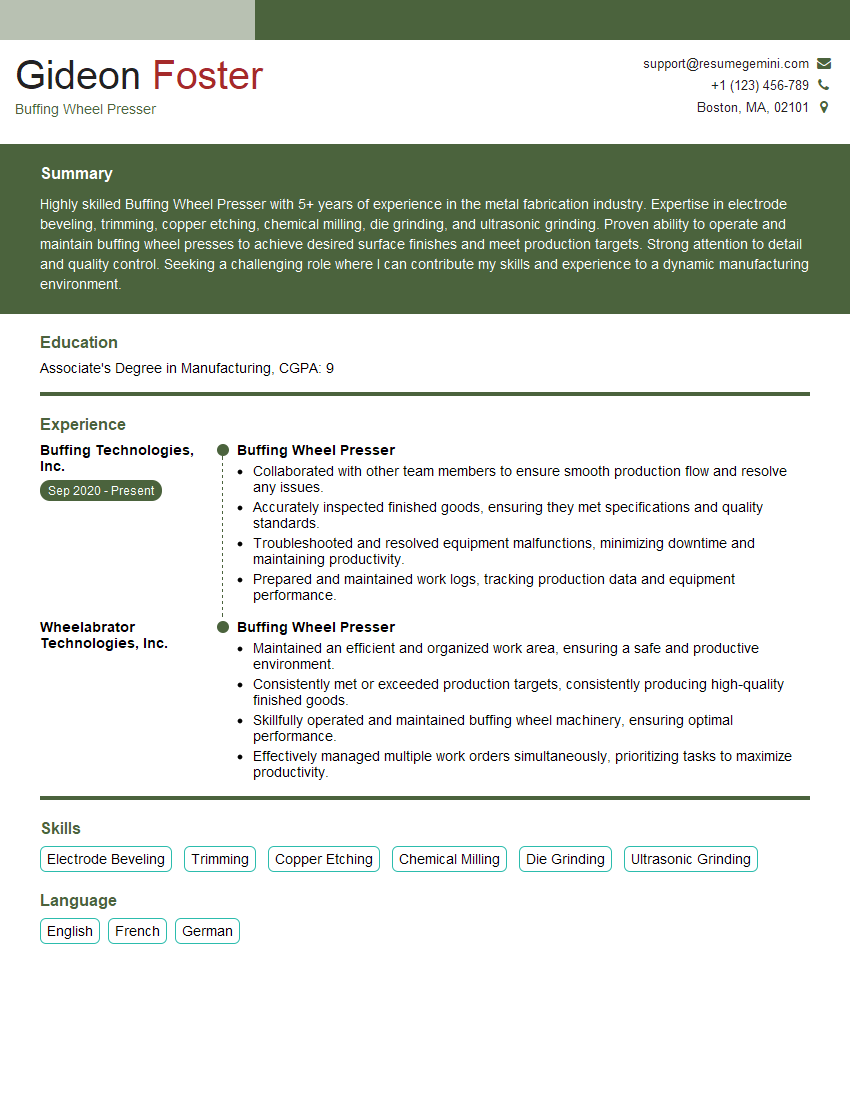

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Buffing Wheel Presser

1. What is the purpose of a buffing wheel?

- Buffing wheels are used to create a smooth and polished surface on metal, wood, and plastic products.

- They are typically made of cotton or wool and are attached to a rotating spindle.

- Compound is applied to the buffing wheel, which helps to remove surface imperfections and produce a high-quality finish.

2. What are the different types of buffing wheels?

Types of Buffing Wheels

- Loose muslin wheels are made of unbleached muslin and are used for general-purpose buffing.

- Sewed muslin wheels are made of bleached muslin and are used for finer buffing.

- Sisal wheels are made of sisal fibers and are used for heavy-duty buffing.

- Polishing wheels are made of felt or other soft materials and are used for final polishing.

Factors to Consider When Choosing a Buffing Wheel

- The material of the workpiece

- The desired finish

- The type of buffing compound being used

- The speed of the buffing wheel

3. What are the safety precautions that must be taken when using a buffing wheel?

- Wear eye protection, gloves, and a dust mask.

- Keep the buffing wheel clean and free of debris.

- Use the correct speed for the material being buffed.

- Hold the workpiece securely.

- Never reach over the buffing wheel while it is running.

4. How do you maintain a buffing wheel?

- Clean the buffing wheel regularly with a brush or compressed air.

- Dress the buffing wheel with a dressing stick or tool to remove any glazing or buildup.

- Store the buffing wheel in a cool, dry place.

5. What are the different types of buffing compounds?

- Tripoli is a coarse compound used for cutting and removing surface imperfections.

- White rouge is a fine compound used for polishing and producing a high-gloss finish.

- Green rouge is a medium-coarse compound used for general-purpose buffing.

- Brown rouge is a fine compound used for polishing and producing a mirror finish.

6. How do you apply buffing compound to a buffing wheel?

- Hold the buffing compound stick against the rotating buffing wheel.

- Apply the compound evenly across the face of the buffing wheel.

- Use a light touch and do not overapply the compound.

7. What are the different techniques for buffing metal?

- Cross buffing is a technique used to remove surface imperfections and create a smooth finish.

- Contour buffing is a technique used to buff irregular surfaces and contours.

- Mirror buffing is a technique used to produce a high-gloss finish on metal surfaces.

8. What are the different techniques for buffing wood?

- Grain buffing is a technique used to follow the grain of the wood and create a smooth finish.

- Cross grain buffing is a technique used to cut against the grain of the wood and remove surface imperfections.

- French polishing is a technique used to produce a high-gloss finish on wood surfaces.

9. What are the different techniques for buffing plastic?

- Fine buffing is a technique used to remove surface imperfections and create a smooth finish.

- Mirror buffing is a technique used to produce a high-gloss finish on plastic surfaces.

10. How do you troubleshoot common buffing problems?

- Chattering is a problem that occurs when the buffing wheel is not properly balanced or dressed.

- Glazing is a problem that occurs when the buffing compound becomes caked on the buffing wheel.

- Loading is a problem that occurs when the buffing wheel becomes clogged with swarf or other debris.

- Burning is a problem that occurs when the buffing wheel is used at too high a speed or pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Buffing Wheel Presser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Buffing Wheel Presser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Buffing Wheel Pressers are responsible for preparing and maintaining buffing wheels, which are used to polish and finish metal surfaces. They may also be responsible for operating buffing machines and performing other related tasks.

1. Prepare and maintain buffing wheels

This involves selecting the appropriate buffing wheel for the job, mounting it on the buffing machine, and dressing it to the desired shape and size. Buffing wheels can be made from a variety of materials, including cotton, sisal, and wool. They can also be impregnated with abrasive compounds, such as aluminum oxide or silicon carbide.

- Select the appropriate buffing wheel for the job.

- Mount the buffing wheel on the buffing machine.

- Dress the buffing wheel to the desired shape and size.

2. Set up and operate buffing machines

This involves adjusting the speed and pressure of the buffing machine to achieve the desired results. Buffing machines can be used to remove burrs and imperfections from metal surfaces, to polish them to a high luster, or to create a specific finish.

- Set up the buffing machine according to the manufacturer’s instructions.

- Adjust the speed and pressure of the buffing machine to achieve the desired results.

- Operate the buffing machine safely and efficiently.

3. Inspect and measure buffed surfaces

This involves visually inspecting the buffed surfaces for defects, such as scratches, pits, or discoloration. Buffing Wheel Pressers may also use measuring tools, such as micrometers or calipers, to ensure that the buffed surfaces meet the required specifications.

- Visually inspect the buffed surfaces for defects.

- Use measuring tools to ensure that the buffed surfaces meet the required specifications.

4. Maintain a clean and organized work area

This involves keeping the buffing area clean and free of debris. Buffing Wheel Pressers may also be responsible for maintaining the buffing machines and other equipment.

- Keep the buffing area clean and free of debris.

- Maintain the buffing machines and other equipment.

Interview Tips

Here are some tips to help you ace your interview for a Buffing Wheel Presser position:

1. Research the company and the position

This will help you understand the company’s culture and what they are looking for in a Buffing Wheel Presser. You can find information about the company on their website, LinkedIn, and other online resources.

- Visit the company’s website.

- Check out the company’s LinkedIn page.

- Read articles about the company in trade publications.

2. Practice your answers to common interview questions

This will help you feel more confident and prepared during your interview. Some common interview questions for Buffing Wheel Pressers include:

- Tell me about your experience preparing and maintaining buffing wheels.

- How do you set up and operate a buffing machine?

- What are some of the common defects that you look for when inspecting buffed surfaces?

3. Be prepared to talk about your safety experience

Working with buffing wheels can be hazardous, so employers will want to know that you are aware of the risks and that you take safety seriously.

- Describe your experience with safety procedures in previous jobs.

- Explain how you would handle a safety hazard in the workplace.

4. Show your enthusiasm for the job

Employers are looking for people who are passionate about their work. Let the interviewer know that you are excited about the opportunity to work as a Buffing Wheel Presser.

- Tell the interviewer why you are interested in the job.

- Explain how your skills and experience make you a good fit for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Buffing Wheel Presser interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!