Are you gearing up for a career in Mixer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mixer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

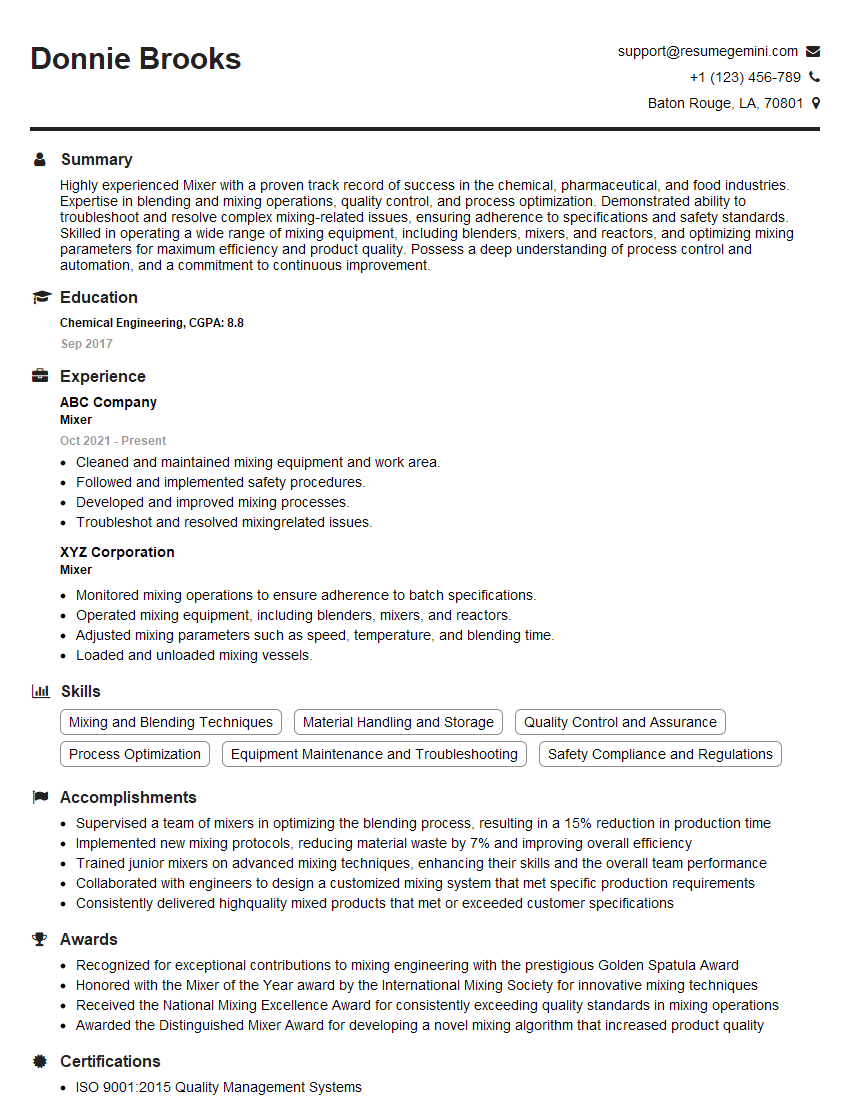

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mixer

1. What are the key components of a mixer and how do they work together to mix ingredients?

Sample Answer:

- Motor: Provides power to rotate the beaters or paddles.

- Speed settings: Allow for different mixing speeds to accommodate various ingredients and techniques.

- Attachments: Include beaters for whisking and whipping, paddles for mixing and folding, and dough hooks for kneading.

- Mixing bowl: Holds the ingredients and provides a contained space for mixing.

- Safety features: May include a locking mechanism to prevent the mixer from operating when the bowl is not properly attached.

2. Describe the difference between a stand mixer and a handheld mixer and discuss the pros and cons of each.

Sample Answer:

Stand Mixer

- Pros: Powerful, hands-free operation, larger capacity, good for heavy mixing tasks.

- Cons: Bulky, can be more expensive, requires counter space.

Handheld Mixer

- Pros: Compact, portable, easy to store, more affordable.

- Cons: Less powerful, requires manual operation, smaller capacity.

3. What are the different types of ingredients that can be mixed using a mixer, and how do you adjust the settings for each?

Sample Answer:

- Light ingredients (whipped cream, egg whites): High speed, whisk attachment.

- Medium ingredients (cake batter, cookie dough): Medium speed, paddle attachment.

- Heavy ingredients (bread dough, yeast dough): Low speed, dough hook attachment.

4. How do you troubleshoot common problems that can occur when using a mixer?

Sample Answer:

- Mixer won’t turn on: Check power cord, ensure bowl is securely attached.

- Attachments not rotating: Ensure attachments are properly inserted.

- Ingredients not mixing properly: Adjust speed or attachment.

- Mixer overheating: Allow for cool-down time, reduce mixing time or speed.

5. What safety precautions should be taken when using a mixer?

Sample Answer:

- Keep hands and hair away from rotating parts.

- Ensure the mixer is properly assembled before use.

- Do not overload the mixing bowl.

- Unplug the mixer before cleaning or making any adjustments.

- Follow manufacturer’s instructions for proper use and maintenance.

6. How do you clean and maintain a mixer to ensure its longevity and optimal performance?

Sample Answer:

- Cleaning: Disassemble mixer, wash attachments and bowl thoroughly, wipe down the base with a damp cloth.

- Maintenance: Check brushes and lubrication regularly, replace worn or damaged parts as needed.

7. What are the latest advancements in mixer technology, and how do they benefit users?

Sample Answer:

- Smart mixers with built-in scales: Monitor weights to ensure accuracy in recipes.

- Multi-function mixers with attachments for juicing, slicing, and grinding: Expand functionality and reduce the need for multiple appliances.

- Induction heating mixers: Heat ingredients directly in the mixing bowl, reducing cooking time.

8. What is the pre/post mixing process to manufacture a product?

Sample Answer:

Pre-Mixing Process:

- Selecting and measuring ingredients.

- Blending dry ingredients.

- Prepping wet ingredients (e.g., melting butter).

Post-Mixing Process:

- Proofing (for yeast-based products).

- Shaping or molding.

- Baking, cooking, or processing.

9. What are the different types of mixers used in the manufacturing of products?

Sample Answer:

- Horizontal mixers: Mix ingredients in a horizontal trough.

- Vertical mixers: Mix ingredients in a vertical cylindrical container.

- Planetary mixers: Mixers with attachments that rotate around a central axis.

- Ribbon mixers: Mixers with ribbon-shaped blades that blend ingredients.

10. How do you control the temperature of ingredients and the mixing process?

Sample Answer:

- Using refrigerated ingredients.

- Mixing in a temperature-controlled environment.

- Monitoring temperature with probes or sensors.

- Adjusting mixing speed and duration to prevent overheating.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mixers are responsible for blending and agitating materials to create various products, such as food, beverages, cosmetics, and pharmaceutical products. They operate industrial mixers and blending equipment to ensure that ingredients are thoroughly combined, maintaining consistent quality and adhering to specified ratios.

1. Equipment Operation

Operate and maintain industrial mixers and blending equipment, ensuring efficient and safe operation.

- Monitor equipment performance, adjust settings, and troubleshoot problems.

- Clean and maintain mixing tanks, pipes, and other equipment.

2. Quality Control

Monitor and control mixing processes to ensure product quality and consistency.

- Collect and analyze samples to verify product specifications.

- Adjust ingredient ratios and mixing parameters to meet quality standards.

3. Production and Scheduling

Plan and coordinate production schedules to meet customer demand.

- Estimate mixing times and material requirements for each product.

- Monitor inventory levels and order supplies as needed.

4. Safety and Compliance

Follow established safety protocols and maintain a clean and organized work environment.

- Wear appropriate personal protective equipment (PPE).

- Adhere to industry regulations and quality assurance standards.

Interview Tips

Preparing for an interview as a Mixer requires researching the specific industry and company you are applying to. Here are some tips to help you ace the interview:

1. Research the Role and Company

Review the job description thoroughly and identify the key responsibilities and qualifications.

- Research the company’s website, news articles, and social media pages to gain insights into their culture and values.

2. Highlight Relevant Skills and Experience

Emphasize your expertise in operating industrial mixers and blending equipment.

- Quantify your accomplishments by providing specific examples of how you ensured product quality and resolved technical issues.

- If applicable, discuss your knowledge of industry regulations and quality assurance standards.

3. Demonstrate Attention to Detail

Mixers need to be meticulous in their work to ensure accurate mixing ratios and product quality.

- During the interview, demonstrate your attention to detail by asking insightful questions and actively listening to the interviewer’s responses.

4. Prepare for Technical Questions

Be ready to answer questions about your technical knowledge and experience with mixing equipment.

- Review common interview questions related to mixer operation, troubleshooting, and safety procedures.

- Consider practicing your responses using the STAR method (Situation, Task, Action, Result).

5. Ask Questions

Asking well-thought-out questions at the end of the interview shows your interest and engagement.

- Prepare questions about the company’s production processes, quality control measures, and safety protocols.

Next Step:

Now that you’re armed with the knowledge of Mixer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mixer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini