Feeling lost in a sea of interview questions? Landed that dream interview for Flatwork Finisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Flatwork Finisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

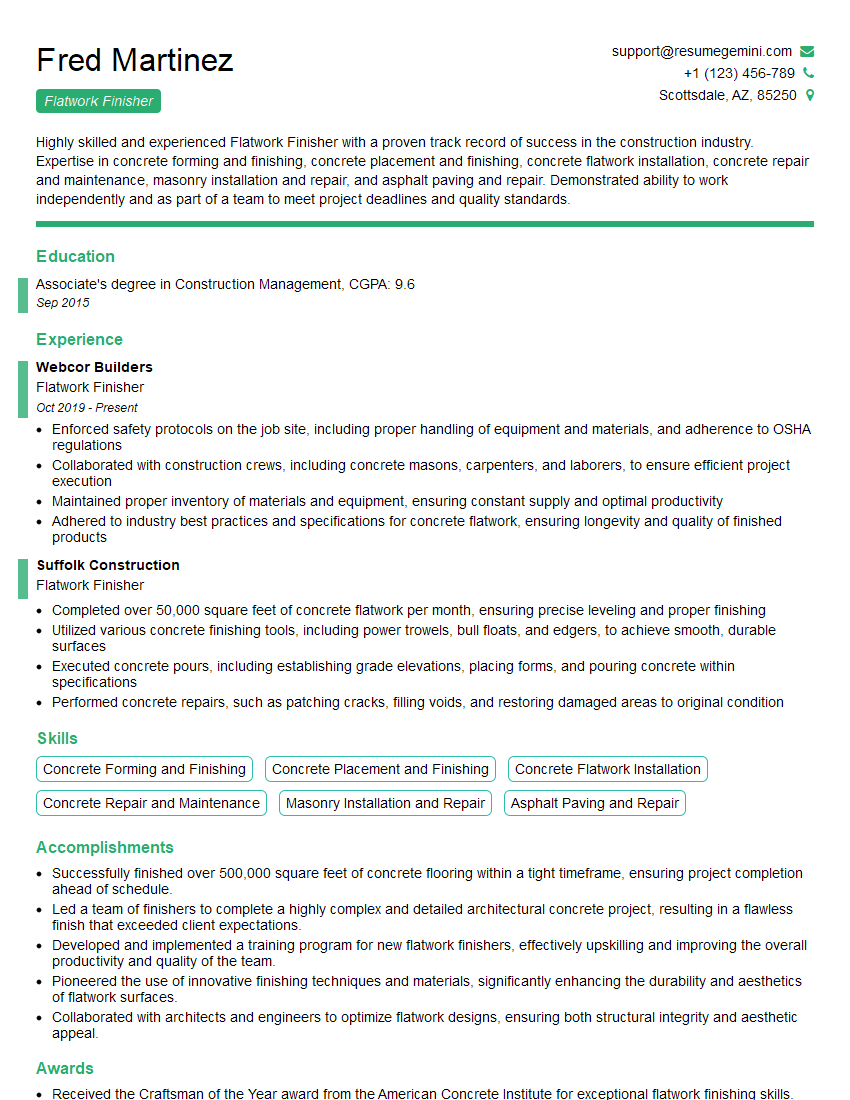

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flatwork Finisher

1. How do you prepare the concrete mix for flatwork finishing?

To prepare the concrete mix for flatwork finishing, I follow these steps:

- Ensure the concrete mix meets the specified strength and workability requirements.

- Calculate the necessary materials and adjust the mix design if needed.

- Set up the concrete mixer and add the ingredients according to the mix design.

- Mix the concrete thoroughly until it reaches the desired consistency.

- Test the concrete mix for slump and adjust the water content as necessary.

2. What is the process of placing and finishing a concrete slab?

Placing the Concrete:

- Set up formwork to define the shape and dimensions of the slab.

- Pour the concrete mix into the formwork, spreading it evenly.

- Consolidate the concrete using a vibrator or tamping tool to remove air pockets.

Finishing the Surface:

- Float the surface to level and smooth it using a bull float.

- Trowel the surface to create a dense and wear-resistant finish.

- Apply a curing compound to protect the concrete from moisture loss.

3. How do you control cracking in concrete flatwork?

To control cracking in concrete flatwork, I employ the following strategies:

- Use a well-proportioned and properly cured concrete mix.

- Provide adequate reinforcement, such as wire mesh or rebar.

- Install control joints to induce cracking in predetermined locations.

- Minimize shrinkage by using shrinkage-reducing admixtures or curing properly.

- Protect the concrete from extreme temperature changes.

4. What techniques do you use to achieve different surface finishes on concrete flatwork?

To create different surface finishes, I utilize various techniques:

- Smooth Trowel Finish: Using a power trowel to achieve a smooth and polished surface.

- Broom Finish: Dragging a broom across the surface to create a textured finish.

- Stamped Concrete: Using concrete stamps to create decorative patterns.

- Exposed Aggregate Finish: Washing away the surface layer to reveal the embedded aggregate.

- Acid Staining: Applying an acid solution to create a unique color and patina.

5. How do you repair and maintain concrete flatwork?

For concrete flatwork repair and maintenance, I follow these steps:

- Identify the cause of the damage and determine the appropriate repair method.

- Clean and prepare the damaged area.

- Apply a bonding agent or primer to ensure proper adhesion.

- Fill the damaged area with a suitable patching material.

- Finish the repair by matching the texture and color of the surrounding concrete.

6. What are the safety precautions you observe when working with concrete flatwork?

To ensure safety, I adhere to the following precautions:

- Wear appropriate personal protective equipment, including gloves, goggles, and a respirator.

- Handle concrete mix with care to avoid spills or splashes.

- Use power tools cautiously and follow proper operating procedures.

- Be aware of electrical hazards and keep equipment properly grounded.

- Work in well-ventilated areas to avoid exposure to dust and fumes.

7. How do you stay updated on the latest techniques and best practices in concrete flatwork?

To stay abreast of industry advancements:

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Network with other professionals in the field.

- Seek certification or continuing education opportunities.

8. What are the key factors that determine the quality of concrete flatwork?

Quality concrete flatwork depends on several factors:

- Proper mix design and material selection.

- Skilled workmanship and attention to detail.

- Adequate curing and protection.

- Compliance with building codes and industry standards.

- Regular maintenance and inspection.

9. How do you handle challenges or unexpected situations during a concrete flatwork project?

When faced with challenges:

- Assess the situation and identify potential solutions.

- Consult with experienced colleagues or a supervisor.

- Stay calm and avoid making hasty decisions.

- Implement the best course of action to address the issue.

- Learn from the experience to improve future performance.

10. Describe a project where you successfully applied innovative techniques to achieve exceptional results in concrete flatwork.

In a recent project, we used a laser screed to level and finish a large outdoor plaza.

- The laser screed ensured a precise and uniform surface.

- We also incorporated a decorative concrete overlay with a stamped pattern.

- The result was a visually appealing and durable plaza that exceeded the client’s expectations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flatwork Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flatwork Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flatwork Finishers are responsible for the final finishing and smoothing of concrete surfaces, ensuring a level and visually appealing finish. Their key job responsibilities include:

1. Surface Preparation

Preparing the concrete surface for finishing by removing debris, leveling it, and applying a bonding agent to enhance adhesion.

2. Screeding and Floating

Using a screed to level the concrete and a float to smooth and compact it, creating a flat and even surface.

3. Finishing Techniques

Applying various finishing techniques to achieve the desired surface texture, including troweling, brushing, or stamping.

4. Joint Finishing

Smoothing and sealing joints between concrete slabs or panels to prevent cracking and water penetration.

5. Curing and Protection

Monitoring the curing process of the concrete and protecting the finished surface from damage by applying sealants or curing compounds.

6. Equipment Maintenance

Maintaining and cleaning equipment used in the finishing process, such as screeds, floats, and power tools.

Interview Tips

To ace your interview for a Flatwork Finisher position, follow these tips:

1. Highlight Your Experience

Emphasize your hands-on experience in concrete finishing, including the techniques you are proficient in and the types of projects you have worked on.

2. Showcase Your Attention to Detail

Flatwork Finishers require a keen eye for detail. Highlight your ability to achieve precise and consistent finishes, ensuring a visually appealing and durable surface.

3. Demonstrate Your Physical Fitness

The job involves physically demanding tasks such as screeding and floating. Demonstrate your physical fitness and ability to work in a physically demanding environment.

4. Highlight Your Safety Awareness

Working with concrete can pose safety risks. Emphasize your knowledge of safety protocols and your commitment to maintaining a safe work environment.

5. Research the Company and Industry

Research the company you are applying to and the concrete finishing industry. This shows that you are genuinely interested in the position and the industry as a whole.

Example Outline:

Question: Tell me about your experience in concrete finishing. Answer: “In my previous role as a Flatwork Finisher for [Company Name], I was responsible for the finishing of commercial and residential concrete surfaces. I am proficient in various finishing techniques, including troweling, brushing, and stamping. I have a keen eye for detail and ensure that each project meets the highest standards of quality.”Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flatwork Finisher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.