Feeling lost in a sea of interview questions? Landed that dream interview for Flatwork Presser but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Flatwork Presser interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

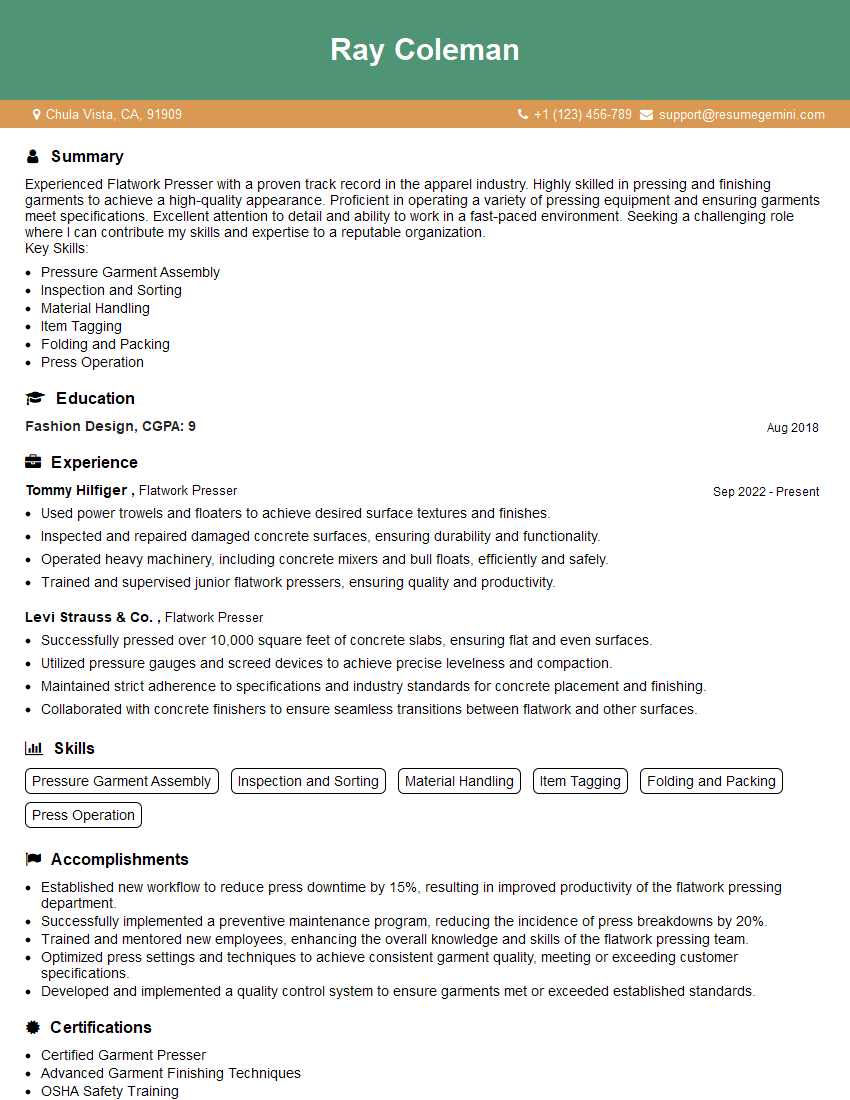

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flatwork Presser

1. What are the different types of flatwork pressers and their applications?

There are various types of flatwork pressers, each designed for specific applications:

- Single-roll press: Used for a wide range of fabrics, providing good press quality and speed.

- Double-roll press: Commonly used for heavy fabrics, providing more pressure for sharper creases.

- Flat-bed press: Ideal for delicate and heat-sensitive fabrics, using a vacuum to hold garments in place without direct contact.

- Revolving-head press: Used for high-volume operations, featuring a rotating head that presses multiple garments simultaneously.

- Shirt press: Specifically designed for pressing shirts, providing a sharp crease on the collar and cuffs.

2. How do you determine the correct pressure and temperature settings for different fabrics?

Considering Fabric Type:

- Delicate fabrics (e.g., silk, lace) require lower pressure and temperature to avoid damage.

- Heavier fabrics (e.g., linen, denim) can withstand higher pressure and temperature for sharper creases.

Using Fabric Labels:

- Always refer to the garment labels for specific care instructions, including recommended pressing temperatures.

- If labels are missing or unclear, test a small, inconspicuous area of the fabric before pressing the entire garment.

Experience and Knowledge:

- With experience, you can develop an intuitive understanding of the ideal settings for different fabrics.

- Attend training or workshops to enhance your knowledge and stay up-to-date with best practices.

3. What techniques do you use to achieve a smooth and wrinkle-free finish on flatwork?

To achieve a smooth and wrinkle-free finish, I employ the following techniques:

- Proper Garment Preparation: Inspect garments for stains or tears and remove any foreign objects before pressing.

- Careful Fabric Handling: Handle fabrics gently to avoid stretching or creasing. Use a pressing cloth for delicate areas.

- Accurate Temperature Control: Set the press to the recommended temperature for the fabric type, preventing scorching or damage.

- Optimal Pressure Application: Apply even pressure across the fabric, avoiding excessive force that can damage the garment.

- Steam Utilization: Use steam effectively to moisten the fabric and facilitate crease removal without causing water stains.

4. How do you maintain and troubleshoot a flatwork presser to ensure optimal performance?

To maintain and troubleshoot a flatwork presser, I follow these key steps:

- Regular Cleaning: Regularly clean the press head, platen, and covers to remove dust, lint, and fabric residue.

- Checking Pressure Adjustment: Ensure the pressure is set correctly for different fabrics to prevent damage or improper pressing.

- Maintaining Optimal Temperature: Calibrate the thermostat regularly to ensure accurate temperature readings and prevent overheating.

- Troubleshooting Common Issues: Address minor issues promptly, such as wrinkles in the fabric (adjust pressure), uneven pressing (clean the platen), or water stains (reduce steam usage).

- Preventive Maintenance: Perform routine inspections and schedule periodic servicing by a qualified technician to maintain the press in optimal condition.

5. What are the safety precautions you observe when operating a flatwork presser?

To ensure a safe work environment, I adhere to the following safety precautions when operating a flatwork presser:

- Proper Training: Ensure adequate training and supervision before operating the press to prevent accidents.

- Guarding and Shields: Wear appropriate hand protection and use the safety shield to prevent contact with hot surfaces.

- Electrical Safety: Check electrical connections regularly and follow proper lockout/tagout procedures during maintenance.

- Steam Safety: Use steam cautiously and maintain a safe distance to avoid burns. Ensure the steam valve is closed when not in use.

- Fire Safety: Keep the work area clear of flammable materials and have a fire extinguisher nearby in case of emergencies.

6. How do you handle garments with special care requirements, such as those made of delicate fabrics or with embellishments?

To handle garments with special care requirements, I follow these specific techniques:

- Delicate Fabrics: Use a pressing cloth or a low-temperature setting to avoid damaging delicate materials like silk or lace.

- Embellishments: Avoid direct contact with presser surfaces to prevent crushing or damaging beads, sequins, or other embellishments.

- Reverse Pressing: Press delicate garments inside out to protect the outer fabric from heat and pressure.

- Steam Control: Use steam sparingly and adjust the steam output to avoid water stains or fabric distortion.

- Test Pressing: Always test a small, inconspicuous area of the garment before pressing the entire piece to ensure compatibility with the pressing settings.

7. What is the importance of maintaining a clean and organized work area for flatwork pressing?

Maintaining a clean and organized work area is crucial for several reasons:

- Quality Control: A clean work area prevents dirt, lint, or foreign objects from transferring onto pressed garments.

- Efficiency: An organized space allows for smooth workflow and minimizes time spent searching for tools or materials.

- Safety: Removing clutter reduces tripping hazards and promotes a safe working environment.

- Fabric Protection: Keeping the area clean prevents dust or debris from settling on fabrics, which could damage delicate materials.

- Professionalism: A well-maintained work area reflects a sense of professionalism and attention to detail.

8. How do you work effectively in a fast-paced and high-volume flatwork pressing environment?

To work effectively in a fast-paced and high-volume pressing environment, I employ the following strategies:

- Time Management: Prioritize tasks and allocate time efficiently to meet production goals.

- Organization: Maintain a well-organized work area to minimize wasted time and increase productivity.

- Multitasking: Handle multiple tasks simultaneously while maintaining accuracy and quality.

- Physical Endurance: Ensure physical stamina to sustain the demands of a physically active role.

- Teamwork: Collaborate effectively with colleagues to handle high volumes and ensure smooth workflow.

9. Can you describe a challenging situation you faced while working as a flatwork presser and how you overcame it?

In a previous role, I encountered a high volume of garments with intricate embellishments. To overcome this challenge, I meticulously adjusted the presser settings and utilized a pressing cloth to protect the embellishments. I also prioritized these garments to ensure they received the necessary care and attention to detail. By carefully managing my time and working diligently, I successfully pressed all the garments while maintaining a high quality standard.

10. What are your career goals and how do you see the role of flatwork presser contributing to your professional development?

As a flatwork presser, I aspire to gain proficiency in all aspects of the craft and contribute to the overall quality of the garments produced. I believe this role will provide me with valuable hands-on experience in fabric care, attention to detail, and time management. Through continuous learning and dedication, I aim to advance my career in the garment industry, potentially specializing in delicate fabric handling or garment restoration.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flatwork Presser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flatwork Presser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flatwork pressers are responsible for ironing and pressing flatwork items such as tablecloths, napkins, sheets, pillowcases, and curtains. They must ensure that the items are pressed to a high standard of quality, with no wrinkles or creases. Flatwork pressers may also be responsible for folding and packing the items.

1. Ironing and pressing flatwork items

Flatwork pressers use a variety of pressing equipment to iron and press flatwork items. They must be able to adjust the temperature and pressure of the equipment to suit the type of fabric they are working with.

- Use a variety of pressing equipment, such as irons, presses, and steamers.

- Adjust the temperature and pressure of the equipment to suit the type of fabric being pressed.

- Iron and press flatwork items to a high standard of quality, with no wrinkles or creases.

2. Folding and packing flatwork items

Flatwork pressers may also be responsible for folding and packing flatwork items. They must be able to fold the items neatly and securely, and they must be able to pack them in a way that prevents wrinkles or creases.

- Fold flatwork items neatly and securely.

- Pack flatwork items in a way that prevents wrinkles or creases.

3. Maintaining a clean and organized work area

Flatwork pressers must maintain a clean and organized work area. They must keep their equipment clean and in good working order, and they must keep their work area free of clutter.

- Keep equipment clean and in good working order.

- Keep work area free of clutter.

4. Following safety procedures

Flatwork pressers must follow all safety procedures when operating pressing equipment. They must be aware of the potential hazards of the equipment, and they must take steps to protect themselves and others from injury.

- Follow all safety procedures when operating pressing equipment.

- Be aware of the potential hazards of the equipment.

- Take steps to protect themselves and others from injury.

Interview Tips

To ace an interview for a flatwork presser position, it is important to be prepared. Here are a few tips to help you prepare for your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and it will also help you to prepare for the specific questions that you may be asked during your interview.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work for the company, if possible.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly during your interview.

- Write down your answers to common interview questions.

- Practice your answers out loud.

- Get feedback from a friend or family member.

3. Dress professionally

It is important to dress professionally for your interview. This shows the interviewer that you are serious about the position and that you respect the company.

- Wear a suit or business dress.

- Make sure your clothes are clean and pressed.

- Accessorize with a tie or scarf.

4. Be on time for your interview

Punctuality is important for any interview. Plan your route in advance and give yourself plenty of time to get to your interview location. Arriving on time shows the interviewer that you are organized and respectful of their time.

- Plan your route in advance.

- Give yourself plenty of time to get to your interview location.

- Arrive on time, even if you have to wait a few minutes.

5. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax and be yourself, and let your personality shine through.

- Be honest and genuine.

- Don’t try to be someone you’re not.

- Let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flatwork Presser interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!