Feeling lost in a sea of interview questions? Landed that dream interview for Hand Flatwork Finisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hand Flatwork Finisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

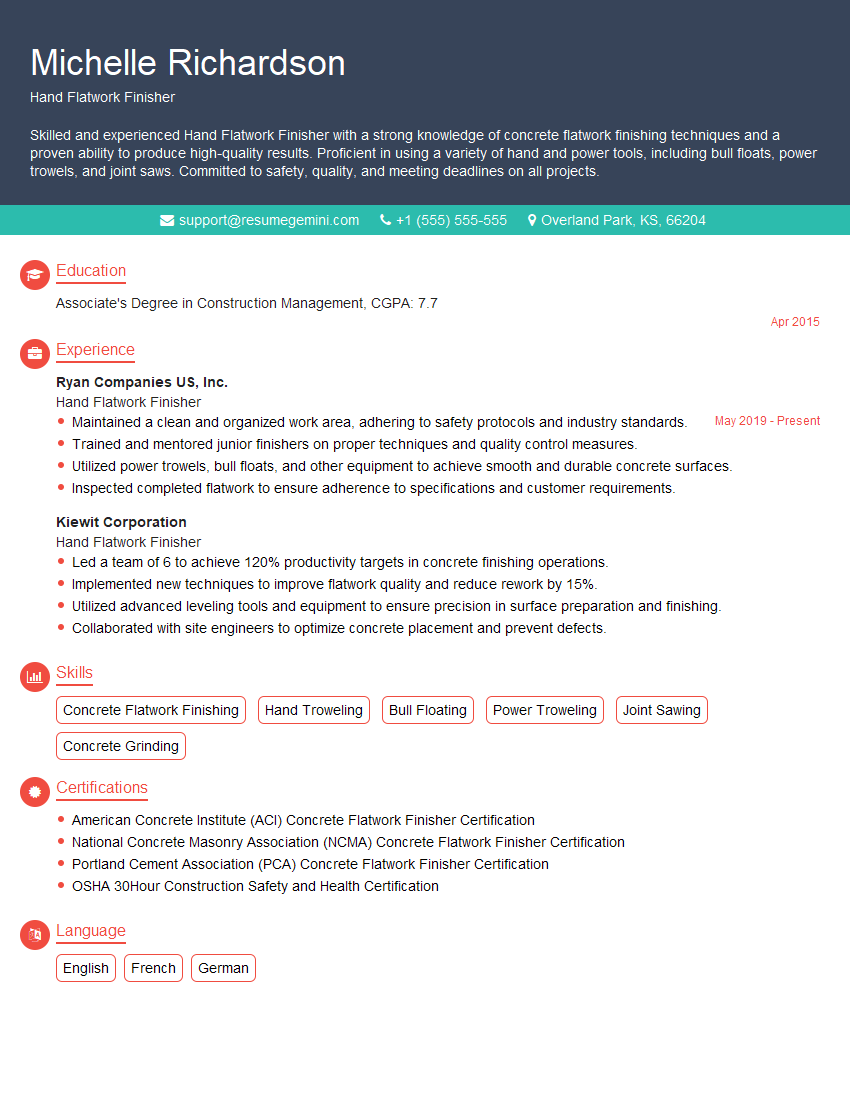

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Flatwork Finisher

1. What are the essential tools and equipment utilized by a Hand Flatwork Finisher?

As a skilled Hand Flatwork Finisher, I am proficient in using a wide range of tools and equipment for surface finishing tasks, including:

- Power trowels and hand trowels for smoothing and leveling concrete surfaces

- Edgers and groovers for creating precision edges and joints

- Floats and bull floats for leveling and floating concrete surfaces

- Specialized finishing tools such as split rollers and texture brushes for creating decorative finishes

- Safety gear, including gloves, eye protection, and dust masks

2. Describe the key steps involved in the hand finishing process for flatwork surfaces.

The hand finishing process for flatwork surfaces typically involves the following sequence of steps:

Surface Preparation

- Inspecting the substrate to ensure proper curing and smoothness

- Cleaning the surface to remove any debris or imperfections

Floating

- Using bull floats to level and consolidate the concrete

- Smoothing the surface with hand floats to remove any imperfections

Troweling

- Power troweling the surface to achieve a dense and smooth finish

- Hand troweling to refine the finish and remove any trowel marks

Edging and Grooving

- Creating clean and precise edges using edgers

- Cutting control joints using groovers to prevent cracking

Curing

- Applying curing compounds or covering the surface to protect it from moisture loss

- Monitoring the curing process to ensure proper strength development

3. What are the common types of surface finishes that can be achieved through hand finishing?

Utilizing various techniques and tools, hand finishing allows for a range of surface finishes to meet different aesthetic and functional requirements:

- Smooth finish: Achieved through meticulous troweling and floating, resulting in a flat and even surface

- Textured finish: Created using specialty tools such as split rollers or texture brushes to enhance traction or decorative appeal

- Exposed aggregate finish: Obtained by removing the surface layer of concrete to reveal the embedded aggregates, providing a unique and durable finish

- Stamped finish: Created using rubber molds to imprint patterns or designs into the concrete surface

4. How do you handle situations where the concrete mix or weather conditions impact the finishing process?

Adapting to challenging concrete mixes or weather conditions is crucial for successful hand finishing:

- Adjusting troweling techniques based on the mix’s workability and setting time

- Monitoring weather conditions and making adjustments, such as using retarders in hot weather or protecting the surface from freezing temperatures

- Consulting with experienced colleagues or supervisors for guidance on handling specific challenges

5. What safety precautions must be observed while performing hand finishing tasks?

Ensuring safety is paramount in hand finishing operations:

- Wearing appropriate personal protective equipment (PPE), including gloves, eye protection, and dust masks

- Maintaining proper work posture and using ergonomic tools to prevent fatigue and injuries

- Handling concrete materials carefully to avoid spills or accidents

- Being aware of potential hazards such as uneven surfaces or electrical wires

- Following company safety protocols and guidelines

6. What techniques do you employ to achieve high-quality and aesthetically pleasing finished surfaces?

Delivering exceptional results requires a combination of technical skills and artistic flair:

- Precise control of troweling and edging techniques to minimize imperfections

- Attention to detail and an eye for aesthetics to ensure a visually appealing finish

- Understanding the principles of concrete curing and proper application of curing compounds

- Working closely with other trades, such as carpenters and masons, to ensure seamless integration of flatwork surfaces

7. How do you stay updated with industry best practices and advancements in hand finishing methods?

Continuous learning is essential for professional growth and delivering exceptional results:

- Attending industry workshops and seminars to stay abreast of new techniques and materials

- Reading trade publications and online resources to stay informed about advancements

- Seeking guidance from experienced professionals or mentors

- Participating in professional organizations and networking with other hand flatwork finishers

8. What is your approach to problem-solving when unexpected challenges arise during a finishing project?

Unexpected challenges are inevitable, and a proactive approach is crucial:

- Assessing the situation thoroughly and identifying potential causes

- Consulting with experienced colleagues or supervisors for advice and alternative solutions

- Implementing corrective measures promptly to minimize the impact on the project timeline

- Documenting lessons learned to prevent similar issues in future projects

9. How do you prioritize tasks and manage your time effectively while working on multiple projects?

Time management and prioritization are essential for success in a fast-paced construction environment:

- Creating a detailed project schedule and breaking down tasks into manageable chunks

- Prioritizing tasks based on urgency and dependency

- Delegating tasks to team members when appropriate

- Maintaining open communication with project managers and colleagues to stay on track

- Utilizing time management tools and techniques to stay organized and efficient

10. Why are you interested in joining our company and what makes you a suitable candidate for this role?

I am eager to join your reputable company because of its commitment to quality and innovation in the construction industry. My passion for hand flatwork finishing, combined with my proven technical skills and dedication to delivering exceptional results, makes me a highly suitable candidate for this role:

- My extensive experience in various hand finishing techniques ensures that I can consistently meet the high standards required by your company.

- My strong work ethic, attention to detail, and ability to work independently and as part of a team make me a valuable asset to any project.

- I am eager to contribute my skills and knowledge to your team and am confident that I can make a positive impact on your company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Flatwork Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Flatwork Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hand Flatwork Finishers are responsible for creating and maintaining smooth, even surfaces on concrete floors, sidewalks, and other flatwork surfaces. They use a variety of hand tools and techniques to achieve the desired finish.

1. Preparing the surface

Before beginning to finish the surface, Hand Flatwork Finishers must prepare the surface by removing any debris or imperfections. This may involve using a broom or compressed air to remove dirt and dust, or using a trowel to fill in any holes or cracks.

2. Applying the finish

Once the surface is prepared, Hand Flatwork Finishers can begin to apply the finish. This may involve using a trowel to spread a thin layer of concrete over the surface, or using a float to smooth out the surface and remove any bumps or ridges.

3. Polishing the surface

Once the finish has been applied, Hand Flatwork Finishers may use a polishing machine to smooth the surface and create a glossy finish. This may involve using a diamond-tipped polishing pad to remove any imperfections and create a smooth, even surface.

4. Maintaining the surface

Once the surface has been finished, Hand Flatwork Finishers are responsible for maintaining the surface and keeping it in good condition. This may involve cleaning the surface with a broom or mop, or applying a sealant to protect the surface from wear and tear.

Interview Tips

Preparing for an interview for a Hand Flatwork Finisher position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the company and the position

Before you go to an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the position. You can find this information on the company’s website, in industry publications, or by talking to people who work at the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that Hand Flatwork Finishers are likely to be asked. These questions may include:

- Tell me about your experience as a Hand Flatwork Finisher.

- What are your strengths and weaknesses as a Hand Flatwork Finisher?

- Why do you want to work for this company?

- What are your salary expectations?

You can practice your answers to these questions by talking to a friend or family member, or by recording yourself and watching it back.

3. Be prepared to talk about your experience

In addition to practicing your answers to common interview questions, you should also be prepared to talk about your experience as a Hand Flatwork Finisher. This may include discussing your specific skills and abilities, as well as your experience working on different types of projects.

4. Be confident and professional

First impressions matter, so it is important to be confident and professional during your interview. This means dressing appropriately, being on time, and making eye contact with the interviewer. It is also important to be honest and enthusiastic about your work.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hand Flatwork Finisher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hand Flatwork Finisher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.